Method of preparing and constructing rubber asphalt waterproof paint without bulge defect

A rubber asphalt and waterproof coating technology, applied in the field of materials, can solve problems such as serious bulging, substandard concrete, and serious sanding, and achieve the effects of strong sunlight resistance and durability, excellent waterproof quality, and high physical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

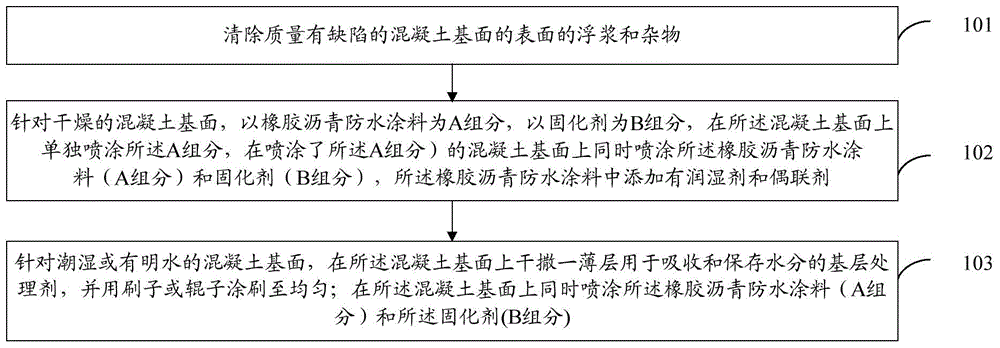

Method used

Image

Examples

Embodiment 1

[0063] Rubber asphalt waterproof coating consists of the following components:

[0064] 90kg of vulcanized rubber modified anionic emulsified asphalt (including: 87.3kg (97%) of asphalt and 2.7kg (3%) of styrene-butadiene-styrene block copolymer)

[0065] 10kg of rubber latex (chloroprene rubber)

[0066] 0.1kg of surfactant (rosin soap)

[0067] 0.1kg of dispersant (condensed naphthalenesulfonic acid sodium salt)

[0068] 0.1kg of stabilizer (sodium alkyl sulfate)

[0069] 0.7 kg of sunscreen (hydrophilic 2-(2-hydroxyphenyl)-benzotriazole UV absorber)

[0070] 0.1kg of defoamer (organic silicon)

[0071] 0.1kg anti-aging agent (N,N'-xylyl-p-phenylenediamine)

[0072] 0.1 kg of wetting agent (sodium ethoxylated alkyl sulfate)

[0073] 0.1 kg of coupling agent (chlorinated methacrylic acid complex).

Embodiment 2

[0075] Rubber asphalt waterproof coating consists of the following components:

[0076] 50kg of vulcanized rubber-modified anionic emulsified asphalt (including: 42.5kg (85%) of asphalt and 7.5kg (15%) of thermoplastic polyolefin-based elastomers of binary ethylene-propylene rubber and EPDM rubber)

[0077] 50kg of latex rubber (Nitrile and Polyisoprene)

[0078] 2 kg of surfactants (alkyldiphenyl ether disulfonates and nonylphenol ethoxylates)

[0079] 0.5kg of dispersant (condensed state naphthalenesulfonic acid sodium salt)

[0080] 0.5kg of stabilizer (sodium alkyl sulfate)

[0081] 0.1kg of sunscreen (hindered amine light stabilizer)

[0082] 0.6kg of defoamer (organic silicon)

[0083] 1kg anti-aging agent (N,N'-xylyl-p-phenylenediamine)

[0084] 1.0kg of wetting agent (octylphenol ethoxylate)

[0085] 1.0kg of coupling agent (methacrylic acid chlorinated complex and Aminopropyltriethoxysilane ).

Embodiment 3

[0087] Rubber asphalt waterproof coating consists of the following components:

[0088] 30kg of vulcanized rubber-modified anionic emulsified asphalt (among them, 21kg (70%) of asphalt and 9kg (30%) of vulcanized styrene-butadiene rubber, vulcanized polyisoprene rubber, vulcanized cis-1, 4-polybutadiene rubber and EPDM rubber)

[0089] 70kg of rubber emulsion (cis-1,4-polybutadiene rubber, carboxylated chloroprene rubber, carboxylated styrene-butadiene rubber)

[0090] 3kg of surfactants (rosin soap, fatty acid soap and sulfated methyl oleate sodium glutamate)

[0091] 2kg of dispersant (condensed state naphthalenesulfonic acid sodium salt)

[0092] 1 kg of stabilizer (sodium alkyl sulfate)

[0093] 2kg of sunscreen (sunscreen containing hindered amine light stabilizers (HALS))

[0094] 1kg of defoamer (organic silicon)

[0095] 0.5kg anti-aging agent (N,N'-xylyl-p-phenylenediamine)

[0096] 2.0 kg of wetting agent (sodium dodecylbenzene sulfonate and laureth (7))

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com