Medium-temperature type anti-corrosion fluoroaluminate soldering flux and preparation method thereof

A technology for etching fluoroaluminate and brazing flux, which is applied in the field of medium-temperature anti-corrosion brazing flux and its preparation, can solve the problems of difficult industrialization, scarcity of cesium resources, high operating temperature, etc., achieve low price, shorten production process, Effects that solve extraction difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

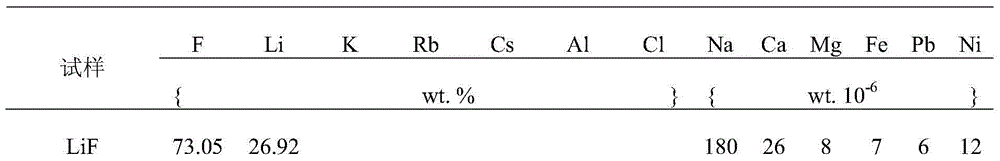

Embodiment 1

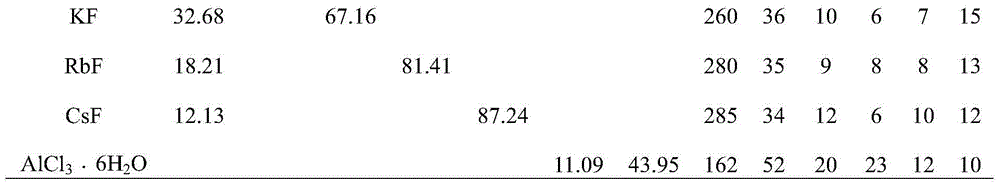

[0054] Preparation of brazing flux: take 1 in Table 2 # The solution is the raw material solution, quantitatively take 1000mL, weigh quantitative AlCl 3 ﹒ 6H 2 Add O1081g and KF 126.11g to the raw material solution, and then add ionized water to dissolve to make a solution. After the dissolution is completed, add 745mL of hydrofluoric acid solution drop by drop, while stirring continuously, so that the two fully react, and the flocculated slurry is filtered , washed and dried to get Rb 3 AlF 6 -RbAlF 4 -Cs 3 AlF 6 -K 3 AlF 6 Quaternary eutectic new brazing flux, then crushed and sieved to obtain 1 # sample. Control the mass ratio of RbF to 30.74wt.%, the mass ratio of KF to 20.66wt.%, AlF 3 The mass ratio is 40.85wt.%, and the mass fraction of CsF is 6.88wt.%.

Embodiment 2

[0056] Preparation of brazing flux: 2 in Table 2 # The solution is the raw material solution, quantitatively take 1000mL, weigh quantitative AlCl 3 ﹒ 6H 2 Add 3.45g of O1563.45g, 194.55g of KF and 585.55g of CsF to the raw material solution, and then add ionized water to dissolve to make a solution. After the dissolution is completed, add 1014mL of hydrofluoric acid solution drop by drop, while stirring continuously to make the two fully react , the obtained flocculation slurry was filtered, washed and dried to obtain Rb 3 AlF 6 -CsAlF 4 -Cs 3 AlF 6 -K 3 AlF 6 Quaternary eutectic new brazing flux, then crushed and sieved to obtain 2 # sample. Control the mass ratio of CsF to 40wt.%, the mass ratio of KF to 15wt.%, the mass ratio of RbF to 15wt.%, AlF 3 The mass ratio is 38.95wt.%.

Embodiment 3

[0058] Preparation of brazing flux: according to 3 in Table 2 # The solution is the raw material solution, quantitatively take 1000mL, then add LiF 12.5g, KF 143g, CsF100g and AlCl 3 ﹒ 6H 2 O 1400g was heated and stirred to dissolve, and after being completely dissolved, 774mL of hydrofluoric acid was slowly added, and at the same time, it was continuously stirred to make the two fully react, and the flocculated slurry was filtered, washed, and dried to obtain a new type of brazing flux mixed with fluoroaluminate. Then crush and sieve to obtain 3 # sample. Control the mass ratio of RbF to 24wt.%, the mass ratio of CsF to 15.5wt.%, the mass ratio of KF to 18.75wt.%, AlF 3 The mass ratio is 43wt.%, the mass fraction of NaF is 0.5wt.%, and the mass fraction of LiF is 1.5wt.%. The preparation of fluoroaluminate by using the lithium sinking mother liquor greatly shortens the process flow and reduces the production cost, which is beneficial to industrial production. The modifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com