Low temperature electrolyte for lithium-ion power battery and preparation method thereof

A power battery and lithium-ion technology, which is applied in the field of low-temperature electrolyte for lithium-ion power batteries and its preparation, can solve problems such as poor low-temperature performance of the electrolyte, achieve the effects of reducing content, improving low-temperature performance, and improving low-temperature discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

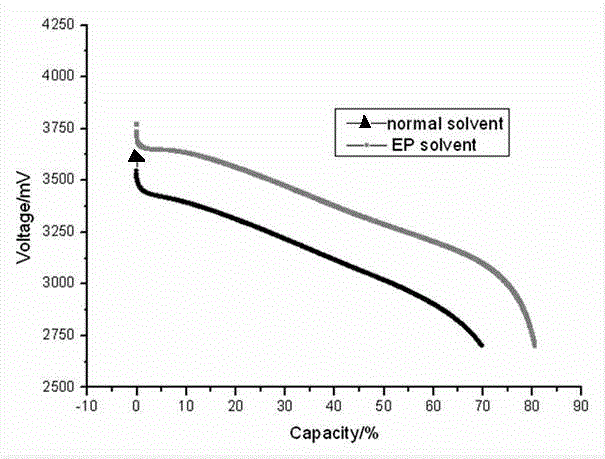

Image

Examples

Embodiment 1

[0030] A preparation method of a low-temperature electrolyte for a lithium-ion power battery, the preparation method is as follows: in a dry, nitrogen-filled glove box, ethylene carbonate, ethyl methyl carbonate, and ethyl propionate are uniformly mixed according to the ratio, and the magnetic induction Stir at 2500GS for 25 minutes, then add additives while stirring within 2 minutes, and continue stirring for 15 minutes at a magnetic induction of 1000GS; then slowly add the solute lithium hexafluorophosphate according to the ratio, turn off the magnetic field, and continue stirring for 30 minutes to obtain a low-temperature electrolyte for lithium-ion power batteries. Among them, the additives are vinyl sulfite and lithium difluorooxalate borate, and the mass parts of each component are 20 parts of ethylene carbonate, 38 parts of ethyl methyl carbonate, 40 parts of ethyl propionate, 1.5 parts of vinyl sulfite and 0.5 part of lithium difluorooxalate borate, and the electrolyte ...

Embodiment 2

[0033] A preparation method of a low-temperature electrolyte for a lithium-ion power battery, the preparation method is as follows: in a dry, nitrogen-filled glove box, ethylene carbonate, ethyl methyl carbonate, and ethyl propionate are uniformly mixed according to the ratio, and the magnetic induction Stir at 2800GS for 30 minutes, then add additives while stirring within 2.5 minutes, and continue stirring for 18 minutes at a magnetic induction of 1200GS; then slowly add the solute lithium hexafluorophosphate according to the ratio, turn off the magnetic field, and continue stirring for 40 minutes to obtain a low-temperature electrolyte for lithium-ion power batteries. Among them, the additives are vinyl sulfite and lithium difluorooxalate borate, and the mass parts of each component are 28 parts of ethylene carbonate, 35 parts of ethyl methyl carbonate, 35 parts of ethyl propionate, 1.8 parts of vinyl sulfite and 0.2 parts of lithium difluorooxalate borate, and the electroly...

Embodiment 3

[0036] A preparation method of a low-temperature electrolyte for a lithium-ion power battery, the preparation method is as follows: in a dry, nitrogen-filled glove box, ethylene carbonate, ethyl methyl carbonate, and ethyl propionate are uniformly mixed according to the ratio, and the magnetic induction The intensity is 3000GS and stirred for 35 minutes, then add the additive while stirring within 3 minutes, the magnetic induction intensity is 1500GS and continue to stir for 20 minutes; then slowly add the solute lithium hexafluorophosphate according to the proportion, turn off the magnetic field, and continue stirring for 45 minutes to obtain a low-temperature electrolyte for lithium-ion power batteries. Among them, the additives are vinyl sulfite and lithium difluorooxalate borate, and the mass parts of each component are 23 parts of ethylene carbonate, 37 parts of ethyl methyl carbonate, 38 parts of ethyl propionate, 1.7 parts of vinyl sulfite and 0.3 parts of lithium difluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com