Production method of novel ultra-comfortable moisture-absorbing strong high-molecular-weight polyethylene fiber/viscose blended yarn

A technology of ultra-high molecular weight and polyethylene fiber, which is applied in the direction of yarn, textiles and papermaking, etc. It can solve the problems of low strength of viscose fiber, which limits the development and cannot meet the needs of consumption, and achieves the advantages of expanding the use of clothing, superior moisture absorption and superior strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

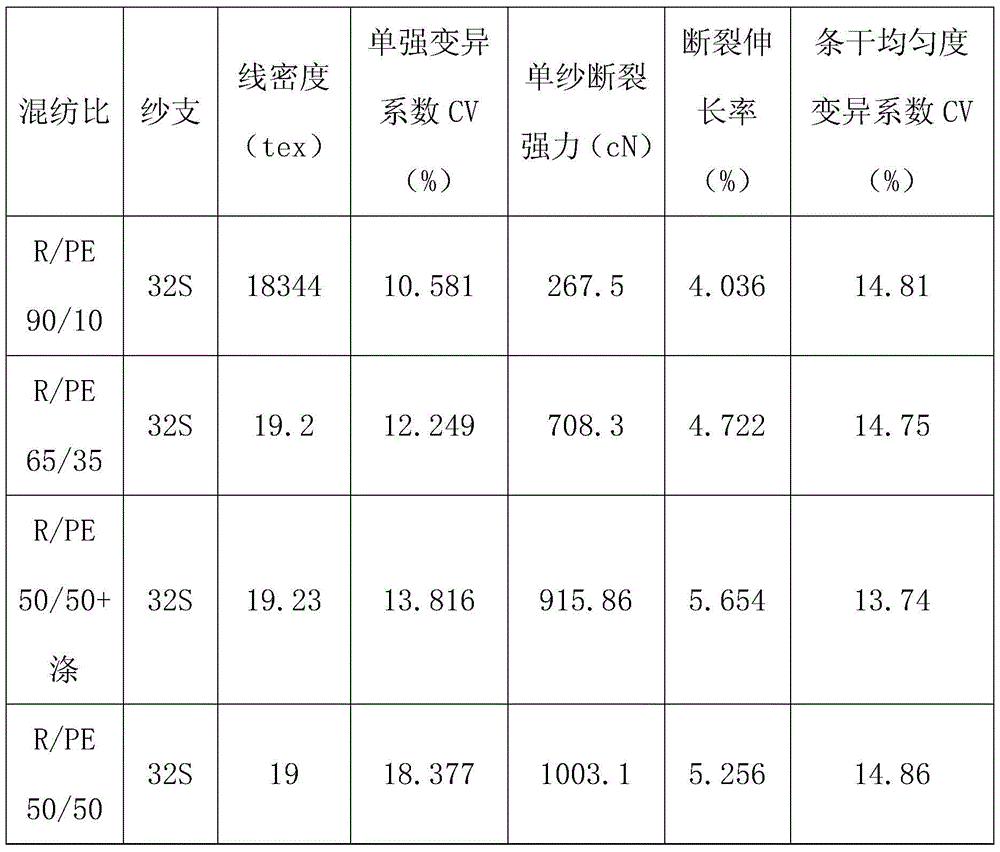

Image

Examples

specific Embodiment 1

[0014] A production method of a novel ultra-comfortable moisture-absorbing strong ultra-high molecular weight polyethylene fiber / viscose blended yarn, which is formed by blending ultra-high molecular weight polyethylene fiber and viscose fiber, and the high molecular weight polyethylene fiber / viscose The blending ratio of the blended yarn is: 10% of ultra-high molecular weight polyethylene fiber, 50% of viscose fiber, and 1% of polyester staple fiber; the length of the fiber is 51mm, and the count of the blended yarn is 10 S , before spinning, the ultra-high molecular weight polyethylene staple fiber is pretreated with antistatic softness and humidity, and it is stuffed for 24 hours. After the pretreatment, it is processed by blending, cleaning, carding, drawing, roving, spun yarn, and self-winding Made into a new type of ultra-comfortable moisture-absorbing strong UHMWPE fiber / viscose blended yarn.

[0015] Prepare Clariant antistatic agent HS-1 as a 1% (weight) solution and ...

specific Embodiment 2

[0021] A production method of a novel ultra-comfortable moisture-absorbing strong ultra-high molecular weight polyethylene fiber / viscose blended yarn, which is formed by blending ultra-high molecular weight polyethylene fiber and viscose fiber, and the high molecular weight polyethylene fiber / viscose The blending ratio of the blended yarn is: ultra-high molecular weight polyethylene fiber 50%, viscose fiber 40%, polyester staple fiber 10%; the length of the fiber is 51mm, and the count of the blended yarn is 40 S , before spinning, the ultra-high molecular weight polyethylene staple fiber is pretreated with antistatic softness and humidity, and it is stuffed for 24-36 hours. After pretreatment, it is mixed, cleaned, carded, drawn, roving, spun, and self-winding A new type of ultra-comfortable moisture-absorbing and strong ultra-high molecular weight polyethylene fiber / viscose blended yarn is processed into a barrel.

[0022] Prepare Clariant antistatic agent HS-1 as a 5% (weig...

specific Embodiment 3

[0028]A production method of a novel ultra-comfortable moisture-absorbing strong ultra-high molecular weight polyethylene fiber / viscose blended yarn, which is formed by blending ultra-high molecular weight polyethylene fiber and viscose fiber, and the high molecular weight polyethylene fiber / viscose The blending ratio of the blended yarn is: ultra-high molecular weight polyethylene fiber 10%, viscose fiber 90%, polyester staple fiber 0%; the length of the fiber is 51mm, and the count of the blended yarn is 30 S , before spinning, the ultra-high molecular weight polyethylene staple fiber is pretreated with antistatic softness and humidity, and it is stuffed for 24-36 hours. After pretreatment, it is mixed, cleaned, carded, drawn, roving, spun, and self-winding A new type of ultra-comfortable moisture-absorbing and strong ultra-high molecular weight polyethylene fiber / viscose blended yarn is processed into a barrel.

[0029] Prepare Clariant antistatic agent HS-1 as a 3% (weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com