Bi-component composite adhesive for solar power back panel, and preparation method thereof

A technology for composite adhesives and solar backsheets, which is applied in the field of two-component polyurethane adhesives, two-component composite polyurethane adhesives and their preparation, and can solve the problem of reduced mechanical properties and thermal stability of adhesives, limited hydrolysis resistance, and adhesive viscosity. Advanced problems, to achieve the effect of improving the curing reaction speed, good hydrolysis resistance, and good UV resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

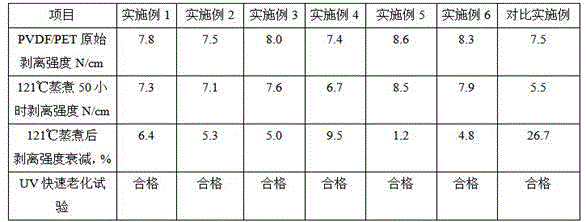

Examples

Embodiment 1

[0025] A two-component composite adhesive for solar back sheets described in this embodiment is composed of A component and B component, wherein, A component is made of the following raw material components in parts by weight: 8 kg of dipropylene glycol, Neopentyl glycol monohydroxypivalate 19.5 kg, 2,4-diethyl-1,5-pentanediol 23 kg, terephthalic acid 12 kg, phthalic anhydride 19 kg, 1,12-lauric acid 18.5 kg Kg, 54.6 kg of ethyl acetate, 1.3 g of dibutyltin dilaurate, 1.6 kg of anti-hydrolysis stabilizer polycarbodiimide STABAXOL P200; component B is HDI trimer; weight of components A and B The ratio is 15:1.

[0026] The preparation method of the above-mentioned two-component composite adhesive for solar backsheets comprises the following steps:

[0027] (1) Preparation of component A:

[0028] Accurately weigh each raw material according to the above-mentioned parts by weight, and put dipropylene glycol, hydroxypivalic acid neopentyl glycol monoester, and 2,4-diethyl-1,5-p...

Embodiment 2

[0033] A two-component composite adhesive for solar back sheets described in this embodiment is composed of component A and component B, wherein component A is made of the following raw material components in parts by weight: 13 kg of dipropylene glycol, Hydroxypivalic acid neopentyl glycol monoester 15 kg, 2,4-diethyl-1,5-pentanediol 22.5 kg, terephthalic acid 10 kg, phthalic anhydride 20 kg, 1,12-lauric acid 19.5 kg Kilogram, 54. 6kg ethyl acetate, 1.6 grams of dibutyltin dilaurate, 2 kilograms of anti-hydrolysis stabilizer polycarbodiimide STABAXOL P200; B component is HDI trimer; the weight ratio of A component to B component It is 15:1.

[0034]The preparation method of the above-mentioned two-component composite adhesive for solar backsheets comprises the following steps:

[0035] (1) Preparation of component A:

[0036] Accurately weigh each raw material according to the above-mentioned parts by weight, and put dipropylene glycol, hydroxypivalic acid neopentyl glycol ...

Embodiment 3

[0040] A two-component composite adhesive for solar back sheets described in this embodiment is composed of component A and component B, wherein component A is made of the following raw material components in parts by weight: 10 kg of dipropylene glycol, Hydroxypivalic acid neopentyl glycol monoester 25 kg, 2,4-diethyl-1,5-pentanediol 15.5 kg, terephthalic acid 10 kg, phthalic anhydride 17 kg, 1,12-lauric acid 22.5 kg Kilogram, 54.6 kilograms of ethyl acetate, 3.2 grams of dibutyltin dilaurate, 2.5 kilograms of anti-hydrolysis stabilizer polycarbodiimide STABAXOL P200; B component is HDI trimer; The weight ratio of A component and B component is 15:1.

[0041] The preparation method of the above-mentioned two-component composite adhesive for solar backsheets comprises the following steps:

[0042] (1) Preparation of component A:

[0043] Accurately weigh each raw material according to the above-mentioned parts by weight, and put dipropylene glycol, hydroxypivalic acid neopen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com