Full-closed commercial induction cooker

A commercial induction cooker and induction cooker technology, applied in the field of induction cooker, can solve the problems of power short circuit, affecting the service life of the fan and heat dissipation performance, easy to corrode electronic components and electromagnetic heating coils, etc., and achieve the effect of preventing power short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

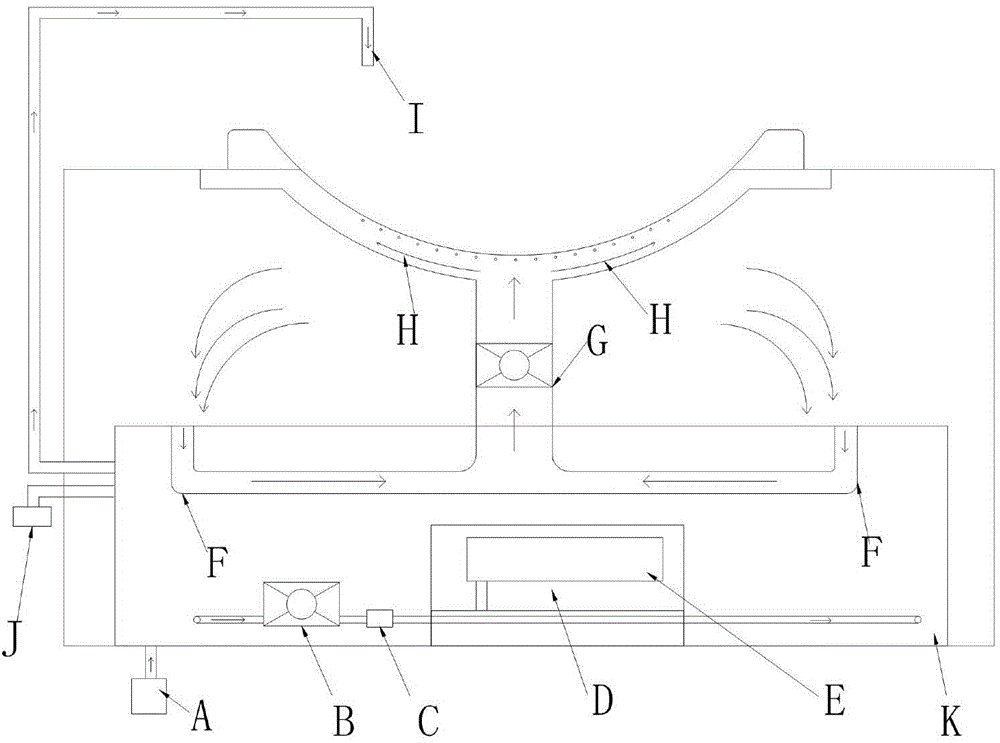

[0009] Such as figure 1 As shown, the fully enclosed commercial induction cooker of the present invention includes a water inlet filter A, a water pump B, an induction cooker core radiator D, an induction cooker core E, a hot air cooling channel F, a coil cooling fan G, a coil cooling channel H, and a faucet I , drain valve J, cooling box K, water filter A is connected to the cooling box, water pump B is located in the cooling box, the radiator D of the induction cooker core is located outside the induction cooker core E, and the hot air cooling channel F is located above the induction cooker core E , the wire reel cooling fan G is located between the hot air cooling channel F and the wire reel cooling channel H, and the faucet I and drain valve J are all communicated with the cooling bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com