Cu<2+> and Fe<3+> doped laminar bismuth fluoride lithium ion cell anode material prepared through liquid phase synthesis and preparation method of bismuth fluoride lithium ion cell anode material

A lithium-ion battery, liquid-phase synthesis technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of harsh process conditions, great influence of electronic transport characteristics, low electronic conductivity, etc., to avoid side reactions product, excellent electrochemical performance, and the effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

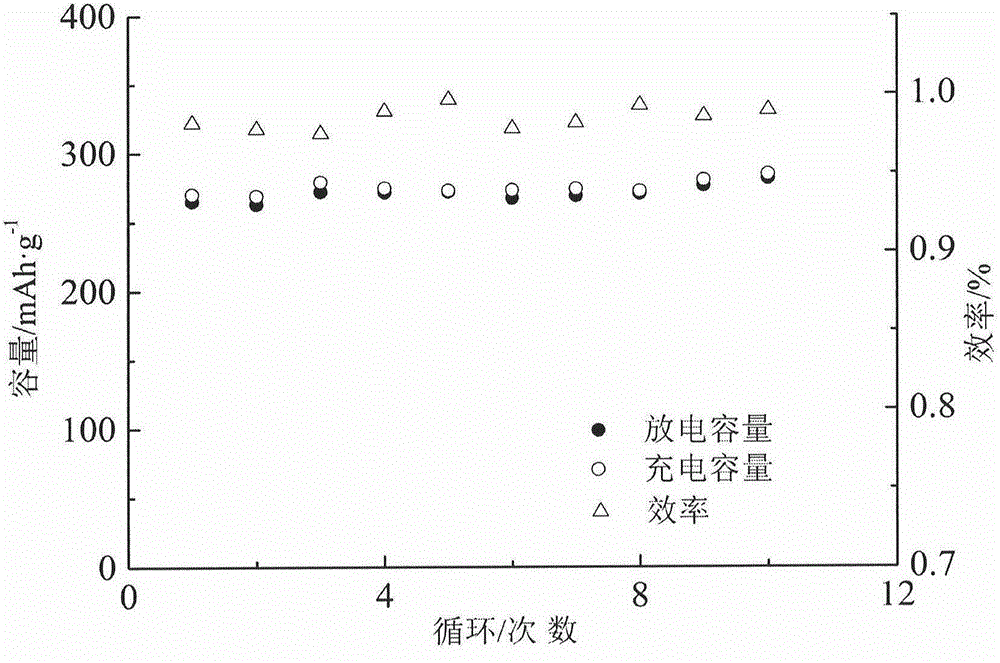

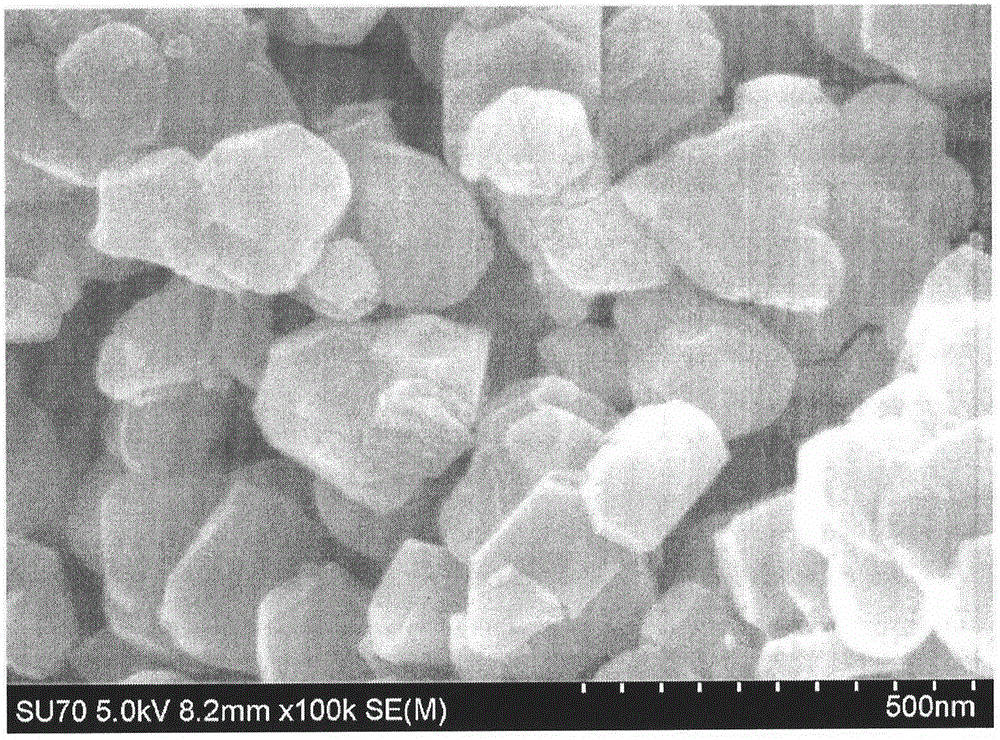

[0018]Embodiment 1: preparation 200mL is composed of 5wt% bismuth nitrate, 1wt% dilute nitric acid, 0.1wt% copper nitrate, 0.1wt% ferric nitrate, 0.1wt% ethanolamine aqueous solution A; preparation 200mL is composed of 15wt% ammonium fluoride, 0.1 Aqueous solution B of polyvinyl alcohol with wt% average molecular weight of 10000-20000; preparation of aqueous solution C consisting of 0.1wt% perfluoroheptanoic acid and 0.1wt% disodium lauryl sulfosuccinic acid monoester; put aqueous solution C into 2L volume , in a cylindrical reactor with an inner diameter of 15 cm to 1 / 3 of the total volume of the reactor, the temperature of the aqueous solution C was set at 40° C. and stirred at a speed of 1250 rpm using a polytetrafluoroethylene stirring paddle with a diameter of 10 cm. Use a peristaltic pump to simultaneously pump the aqueous solution A and the aqueous solution B into the reactor at a speed of 0.1 mL / min until all the prepared aqueous solutions A and B are pumped out. The i...

Embodiment 2

[0019] Embodiment 2: preparation 300mL is composed of 15wt% bismuth nitrate, 0.3wt% copper nitrate, 0.4wt% iron nitrate, 5wt% dilute nitric acid, 0.5wt% aqueous solution A of triethanolamine hydrochloride; preparation 300mL is composed of 45wt% ammonium fluoride , 0.5wt% aqueous solution B of polyvinyl alcohol with an average molecular weight of 10000-20000; the preparation composition is 0.5wt% 2,2-difluorocyclopropanecarboxylic acid and 0.5wt% cocoic acid monoethanolamide sulfosuccinic acid monoester di Sodium aqueous solution C; put aqueous solution C into a cylindrical reactor with a volume of 2L and an inner diameter of 20 cm to 1 / 2 of the total volume of the reactor, set the temperature of aqueous solution C at 60°C and use a cylindrical reactor with a diameter of 15 cm The polytetrafluoroethylene stirring paddle was stirred at a speed of 1500 rpm. Use a peristaltic pump to simultaneously pump the aqueous solution A and the aqueous solution B into the reactor at a rate o...

Embodiment 3

[0020] Example 3: Prepare 250mL of aqueous solution A containing 10wt% bismuth nitrate, 0.2wt% copper nitrate, 0.3wt% ferric nitrate, 3wt% dilute nitric acid, and 0.3wt% triethanolamine; prepare 250mL of 30wt% ammonium fluoride , 0.3wt% op-10 aqueous solution B; the preparation composition is an aqueous solution C of 0.3wt% perfluoroglutaric acid and 0.3wt% potassium monododecyl phosphate; put the aqueous solution C into a 2L volume with an inner diameter of 17 cm In the cylindrical reactor to 2 / 5 of the total volume of the reactor, the temperature of the aqueous solution C was set at 50° C. and stirred at a speed of 1350 rpm using a polytetrafluoroethylene stirring paddle with a diameter of 12 cm. Use a peristaltic pump to simultaneously pump the aqueous solution A and the aqueous solution B into the reactor at a speed of 0.5 mL / min until all the prepared aqueous solutions A and B are pumped out. The inlet of the aqueous solution A into the reactor and the inlet of the aqueou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com