A method for iron extraction by reduction smelting of lead slag

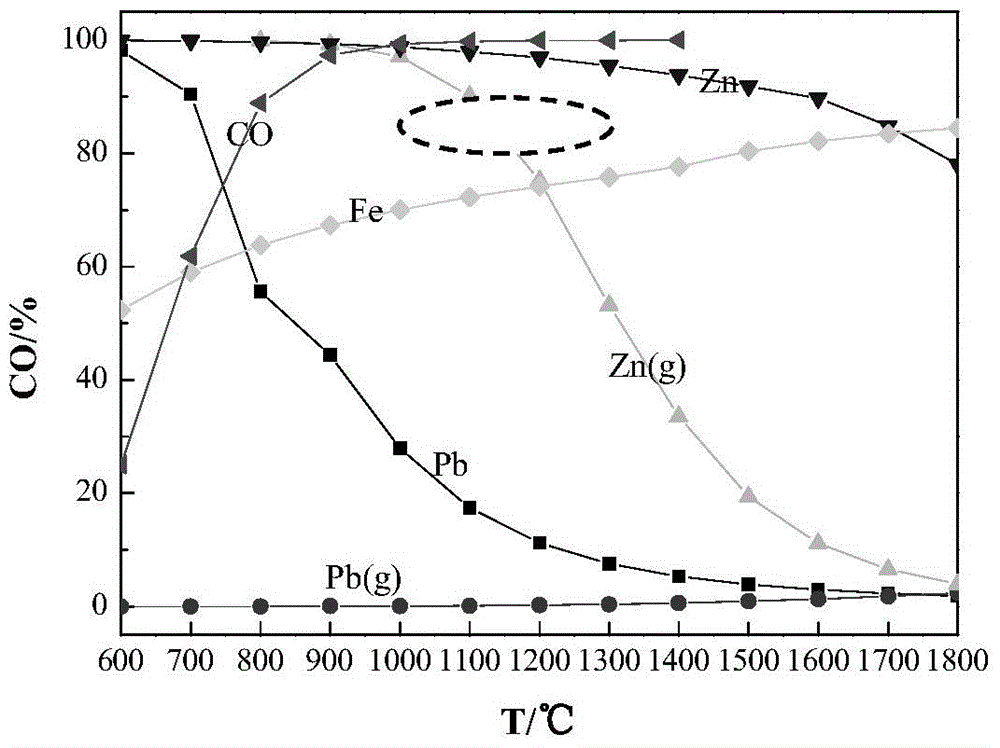

The technology of lead slag and reducing agent is applied in the fields of molten pool smelting, volatilizing and separating lead and zinc, recovering iron, and lead slag reduction smelting and iron extraction, which can solve the problem that iron resources in lead slag cannot be efficiently recycled and reused. Take advantage of the lack of effective methods and other problems to achieve the effects of short smelting time, low carbon consumption and excellent quality of pig iron products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Grind 100g of water-quenched lead slag to -200 mesh (74um) and account for more than 90%. The contents of Zn, Pb, and Fe in the slag are respectively 4.28%, 0.07%, and 22.84%. Add graphite powder C / Fe=1.6, Calcium oxide was added to control the alkalinity to 1.2, mixed evenly, nitrogen was introduced, and smelted at 1575°C for 15 minutes to obtain pig iron with an iron content of 93.74%, and the iron recovery rate was 99.61%.

Embodiment 2

[0032] Grind 100g of unwater-quenched lead slag to -200 mesh (74um) and account for more than 90%. The contents of Zn, Pb, and Fe in the slag are 4.55%, 0.02%, and 30.51% respectively. Add graphite powder C / Fe=1.6 , mixed with calcium oxide to control the alkalinity to 1.2, mixed evenly, fed with nitrogen, and smelted at 1575°C for 15 minutes to obtain pig iron with an iron content of 94.92%, and the iron recovery rate was 96.87%.

Embodiment 3

[0034]Grind 100g of blast furnace slag until -200 mesh (74um) accounts for more than 90%. The contents of Zn, Pb, and Fe in the slag are 12.39%, 2.0%, and 24.10% respectively. Control the alkalinity of calcium oxide to 1.2, mix evenly, pass nitrogen, and melt at 1575°C for 15 minutes to obtain pig iron with an iron content of 93.11%, and the iron recovery rate is 98.58%.

[0035] It can be seen from the above examples that the method of the present invention can effectively recover the iron in the lead slag, the recovery rate of reduction smelting iron is 96.87-99.61%, and the iron content in pig iron is 93.11-94.92%. See Table 1 for the impurity content in pig iron under optimal conditions, and see Table 2 for the national standards for steelmaking pig iron. Comparing Table 1 and Table 2, it can be seen that under the optimal conditions of the present invention, the content of C in the pig iron reaches the national steelmaking pig iron standard, the content of P and S reaches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com