Novel method for purifying and repeatedly using lead and zinc smelting flue gas washing contaminated acid wastewater

The technology of polluted acid wastewater and smelting flue gas is applied in the treatment of lead and zinc smelting flue gas washing polluted acid wastewater, environmental protection metallurgy field, and achieves the effects of high resource recycling rate, simple operation and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

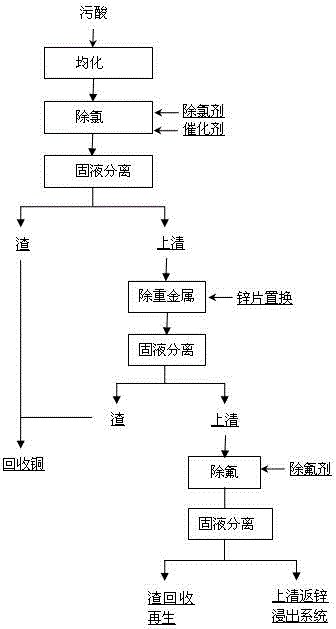

[0020] The invention provides a new method for purifying and reusing lead-zinc smelting flue gas washing polluted acid waste water. The specific process is to homogenize and settle the dirty acid first, and then add the prepared chlorine removal agent and catalyst from the pipeline connecting the supernatant of the homogenization tank and the chlorine removal reaction tank, so that the agent and the dirty acid are fully and uniformly mixed and reacted, and the chlorine removal The addition amount of agent is 0.1%, and the addition amount of catalyst is 0.01%. Continue to remove chlorine in the reaction tank, and the control reaction time is 60 minutes. The supernatant of polluted acid after dechlorination enters the heavy metal removal part. The heavy metal removal part is a reaction tank with stirring. Excessive zinc flakes are accumulated in the reaction tank. in 60 minutes. The polluted acid wastewater passes through the zinc plate replacement reaction tank and enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com