Water-soluble bio-based sulfate/sulfonate preparation process and uses of water-soluble bio-based sulfate/sulfonate as green environmental protection adhesive

A technology of viscose and cellulose sulfate, applied in the field of cellulose sulfate, can solve the problems of poor bonding effect of soluble starch, impossibility of popularization and difficult biodegradability, etc., and achieve excellent water solubility and polymer performance , expand the prospect of wide application, good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

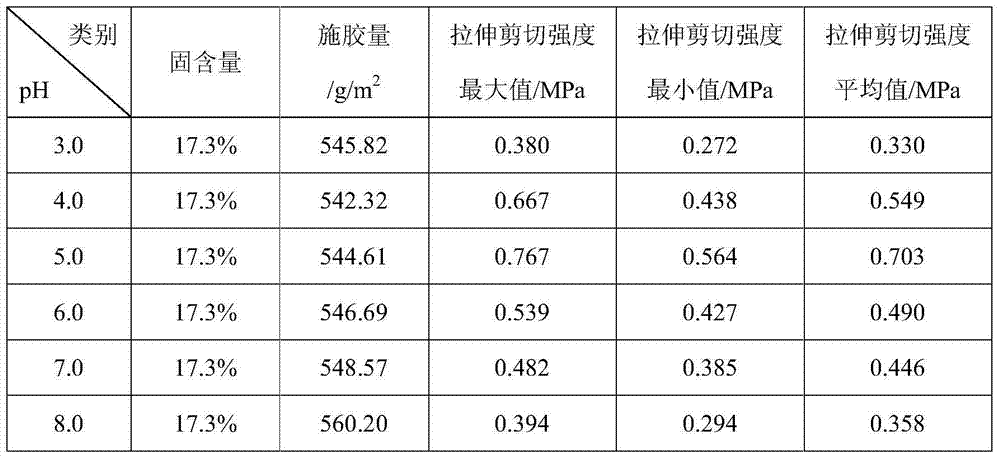

[0036] Liquid SO 3 Soluble in cooled 1,2-dichloroethane to form SO 3 SO with a concentration of 2.9mol / L 3 Dichloroethane solution, under stirring, suspend 80.0g of industrial pulp dried under vacuum at 110°C for 1h in 1600mL of 1,2-dichloroethane, add 200.0mL of SO 3 SO with a concentration of 2.9mol / L 3 / dichloroethane solution, control the temperature rise not to exceed 35°C, adjust the stirring speed to 900rpm, filter and remove the solvent after 4 hours of reaction, slowly add the solid material to a 2.0mol / L-25°C NaOH ice-water mixture for neutralization, and control the temperature No more than 15°C, filter to remove the water-insoluble solid residue, weigh and calculate the conversion rate, the conversion rate is 70%, the degree of substitution (DS) of the product is 1.0, and the adjusted pH is respectively 3, 4, 5, 6, 7 and 8 five liquid products to obtain water-soluble bio-based sulfate adhesives with different pH. According to the national standard GB7124-86, th...

Embodiment 2

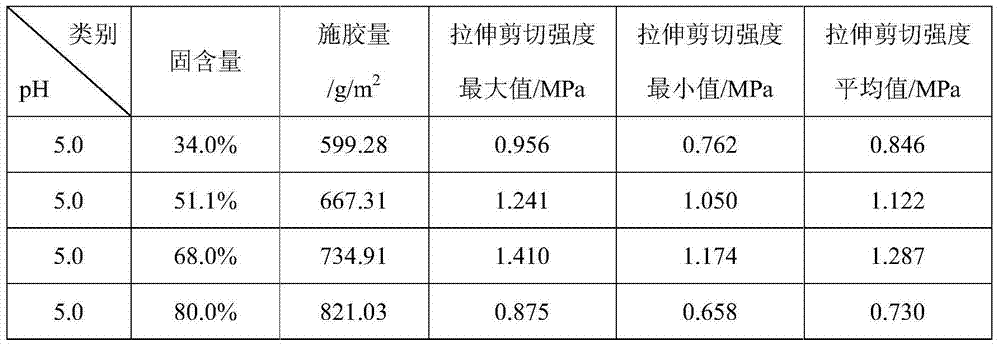

[0041] The liquid product with pH=5 obtained in Example 1 was concentrated to obtain water-soluble biomass-based sulfate viscose adhesives with solid contents of 34.0%, 51.1%, 68.0% and 80%, respectively. According to the national standard GB7124-86 to test its adhesiveness, use wood as the test material, see Table 2 for specific data.

[0042]

[0043] Table 2 The tensile shear strength of different solid content bio-based sulfate salts on wood boards

[0044] It can be seen from the data in Table 2 that the tensile shear strength is the highest when the solid content is within 70%.

Embodiment 3

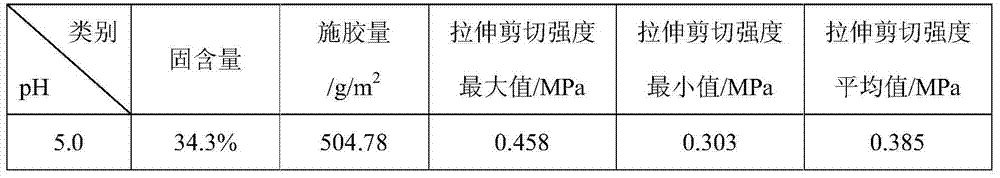

[0046] Gas SO 3 Soluble in 1,2-dichloroethane at -3°C to form SO 3 SO with a concentration of 0.5mol / L 3 Dichloroethane solution, soak 50.0g of bagasse that has been dried under vacuum at 115°C for 5h in 1520mL of 1,2-dichloroethane at 25°C under stirring, add 500.0mL of SO 3 SO with a concentration of 1.0mol / L 3 / dichloroethane solution, stirred at 10°C for 1h, then filtered to remove the solvent, and slowly added the solid material to 2.0m o In the excess NaOH solution of 1 / L 5 ℃, adjust the pH to 5.0, filter to remove the solid residue, weigh and calculate the conversion rate of raw materials, the conversion rate is 20%, and the water-soluble biomass sulfate ester salt viscosity with a degree of substitution (DS) of 0.4 is obtained. Glue. According to the national standard GB7124-86 to test its adhesiveness, aluminum plate is used as the test material. Please refer to Table 3 for the specific data.

[0047]

[0048] The tensile shear strength of the bio-based sulfat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com