WC particle in-situ reinforced hard alloy and steel ultrasonic soldering method

A technology of cemented carbide and brazing method, which is applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc., and can solve the problems of complex preparation of special brazing material, poor impact load resistance, and complex brazing process. , to achieve the effect of high quality brazing, low cost and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

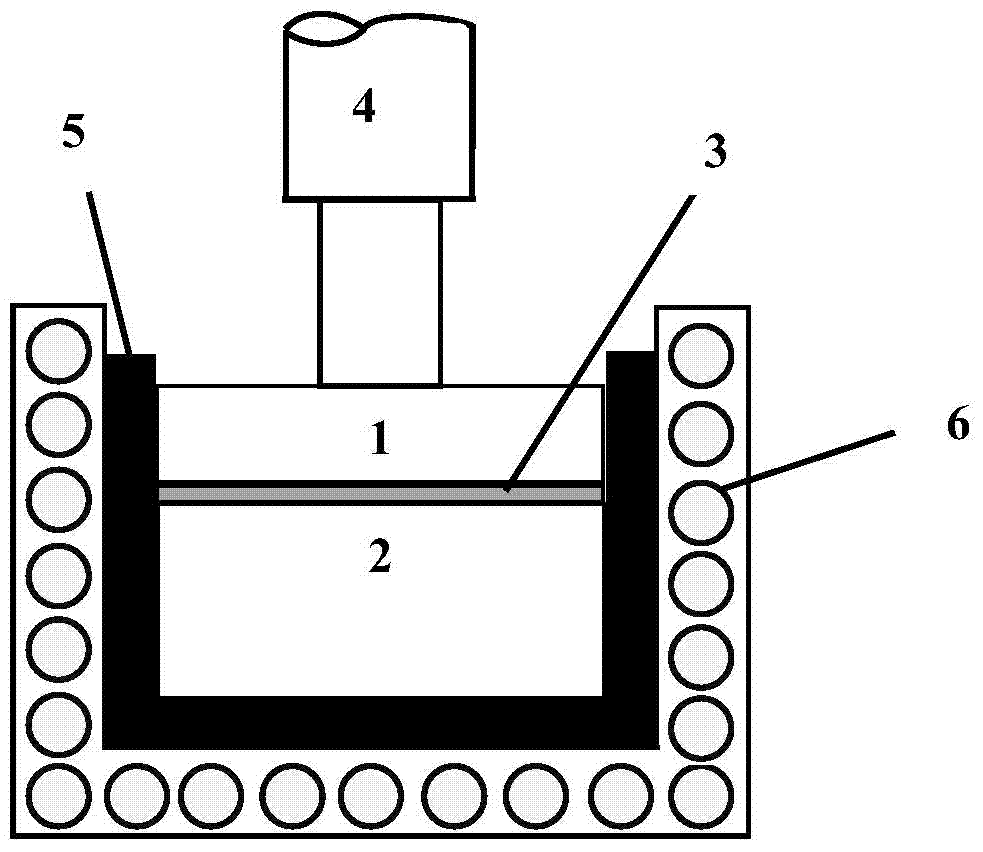

[0017] Such as figure 1 As shown, the embodiment of the present invention is carried out according to the following steps: a, before brazing, grind the surfaces of cemented carbide 1 and steel 2 to be connected respectively, and clean the polished surface with acetone; b, before brazing Place the Ag-based solder foil 3 between the cemented carbide 1 and the steel 2; c, place the ultrasonic head 4 on the surface of the cemented carbide 1 and apply ultrasonic vibration to the cemented carbide and steel to be welded at a temperature of 380°C 5min; d, the brazing process adopts high-frequency induction heating; e, the ultrasonic vibration ends the natural cooling, and the weld seam reinforced by WC ceramic particles is obtained.

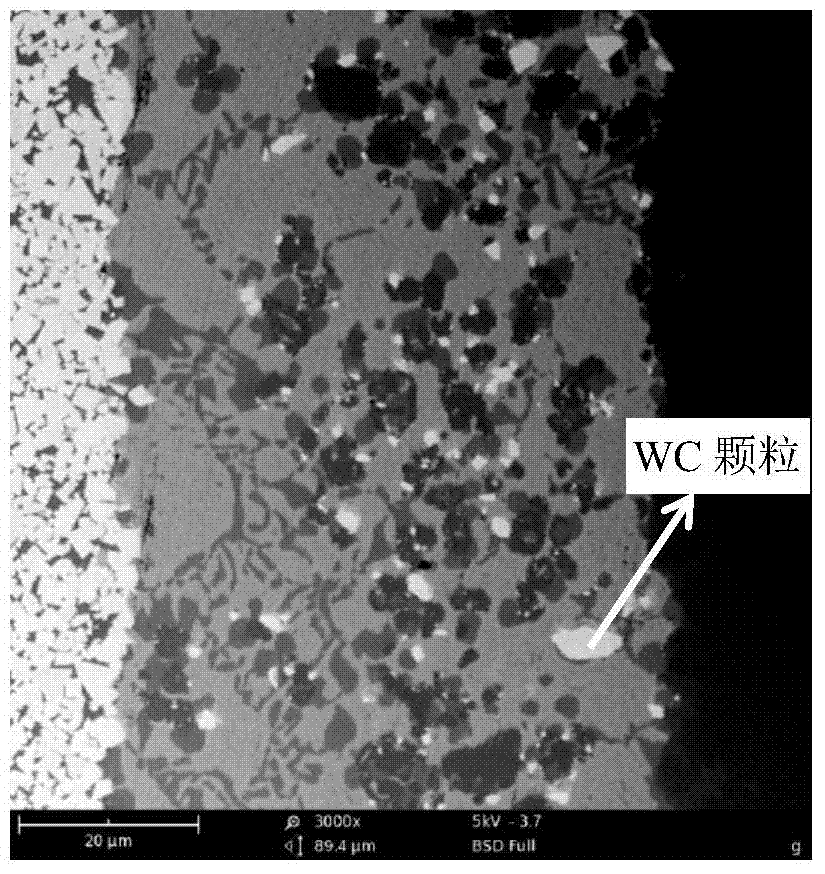

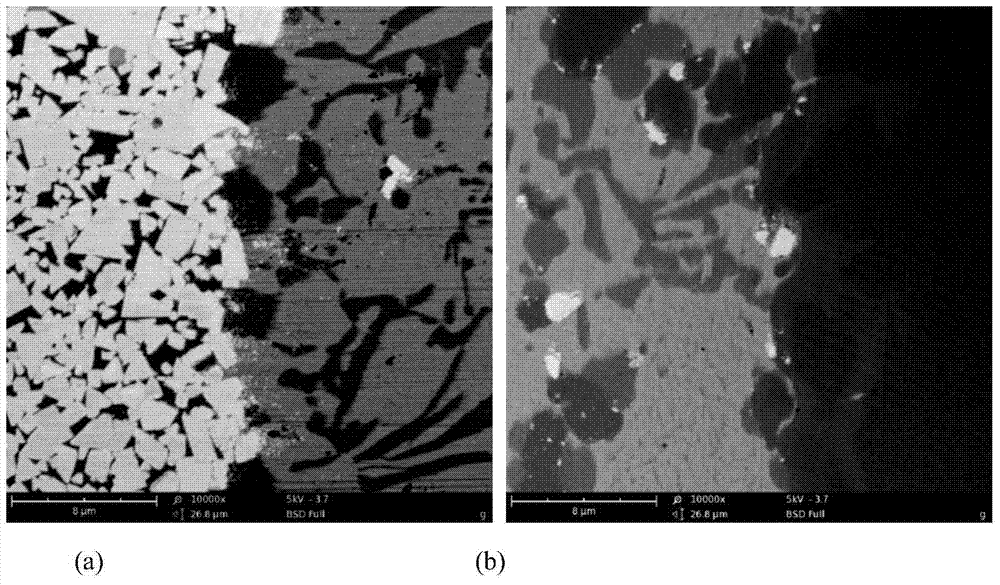

[0018] The microstructure (SEM morphology) of the brazed joint obtained in this embodiment is shown in figure 2 , the double-sided interface structure see image 3 , it can be seen that the interface is well bonded, and white WC particles migrating fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com