Preparation method of silica supported nickel phosphide catalyst

A technology of silica and nickel catalysts, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh 29.7g Ni(NO 3 ) 2 ·6H 2 O was dissolved in water to make a 100ml solution; another 18.9g NaSiO 3 9H 2 O and 11.7 g Na 2 CO 3 Dissolve in water to make 100ml solution. Add the above two solutions dropwise to 200ml of distilled water at the same time under stirring to form a green precipitate. After washing the precipitate with distilled water, add 200ml of n-butanol, evaporate to dryness in a water bath, and then dry it in a 393K oven to obtain Nickel catalyst supported on silicon.

Embodiment 2

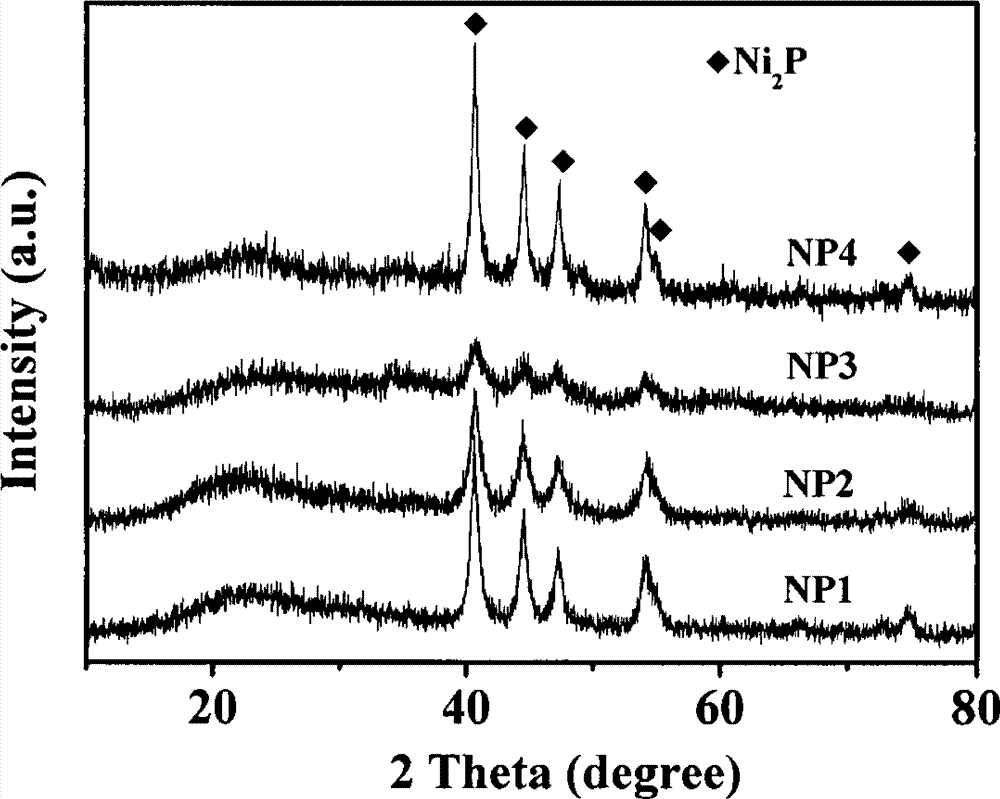

[0018] Weigh 5 g of the silica-supported nickel catalyst of Example 1 and fill it into a reactor, raise the temperature to 673K, feed hydrogen at a flow rate of 100ml / min, reduce the temperature for 2h, then cool down to 543K, and feed 4 wt% triphenyl The n-heptane solution of base phosphine was phosphated for 12h, and the flow rate of n-heptane solution was 15ml / h. 2 Passivate with 1% nitrogen for 12 hours, and the flow rate of nitrogen is 20ml / min, to obtain a passivated silicon dioxide-supported nickel phosphide catalyst. The specific surface area of the prepared catalyst (named NP1) is 123m 2 / g, XRD spectrum is shown in accompanying drawing.

Embodiment 3

[0020] Weigh 5 g of the silica-supported nickel catalyst of Example 1 and fill it into a reactor, raise the temperature to 673K, feed hydrogen at a hydrogen flow rate of 100ml / min, reduce the temperature for 2h, then cool down to 443K, and feed 4wt% triphenyl The n-heptane solution of base phosphine was phosphated for 12h, and the flow rate of n-heptane solution was 15ml / h. 2 Passivate with 1% nitrogen for 12 hours, and the flow rate of nitrogen is 20ml / min, to obtain a passivated silicon dioxide-supported nickel phosphide catalyst. The specific surface area of the prepared catalyst (named NP2) is 197m 2 / g, XRD spectrum is shown in accompanying drawing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com