Method for preparing copper tungstate/nickel phosphate photoanode film with visible light response

A technology of nickel phosphate light and anode film, applied in electrodes, liquid chemical plating, coatings, etc., can solve the problems of inability to meet practical application requirements, slow interface charge transfer rate, fast carrier recombination speed, etc. Copper tungstate photoelectric conversion efficiency, accelerating hole transfer, and increasing carrier lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A preparation method of a copper tungstate / nickel phosphate photoanode film with visible light response, comprising the following steps:

[0016] 1) At room temperature, add 0.1237g of sodium tungstate and 0.1172g of ammonium oxalate into 15ml of deionized aqueous solution, stir and dissolve; then, slowly drop 5ml of hydrochloric acid with a concentration of 3mol / L into the sodium tungstate solution to obtain White emulsion; mix ammonium oxalate solution and sodium tungstate solution, stir for 30 minutes, the solution becomes clear, pour the solution into a hydrothermal reaction kettle, insert FTO conductive glass, heat at 160°C for 4 hours, WO 3 Grow on the surface of FTO glass, wash with water, and dry in air;

[0017] 2) Dissolve 0.2g of copper nitrate in 5ml of acetic acid solution, take 100μL of the solution and add it dropwise to WO 3 The surface of the thin film electrode was dried at room temperature, calcined in a muffle furnace at 550°C for 2 hours, soaked in...

Embodiment 2

[0021] A method for preparing a copper tungstate / nickel phosphate photoanode film with visible light response. The experimental steps are the same as in Example 1. The hydrothermal temperature is changed to 140°C, the hydrothermal time is set to 6h, and copper ions are repeatedly added dropwise for 3 times, so that Tungsten trioxide is completely converted into copper tungstate; add 0.01g of nickel chloride to 150ml of potassium phosphate solution with a concentration of 0.1mol / L to prepare nickel phosphate precipitation, and drop 20μL of nickel phosphate solid dispersion onto the surface of the copper tungstate electrode. Dry at 120°C to obtain a nickel phosphate-modified copper tungstate film electrode.

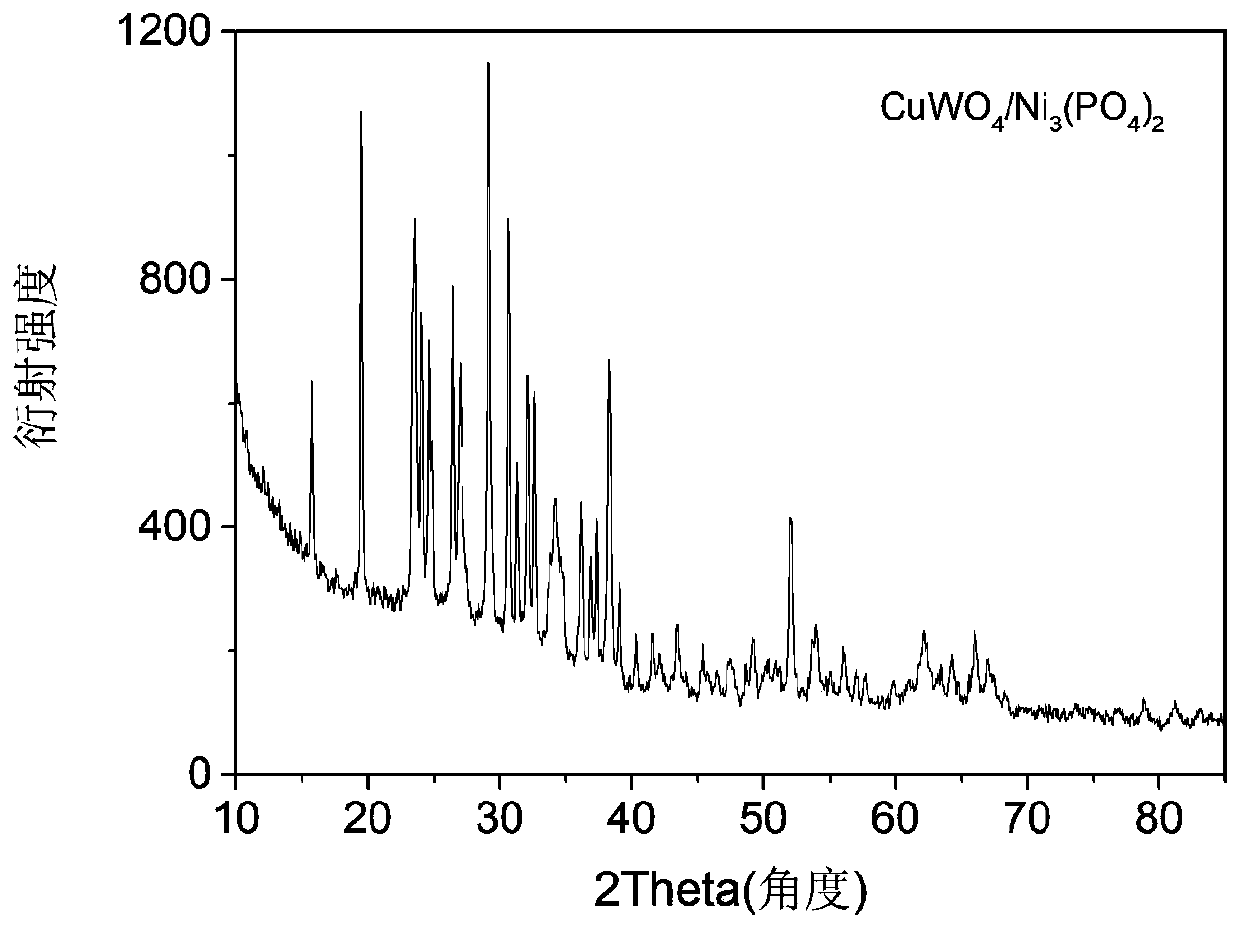

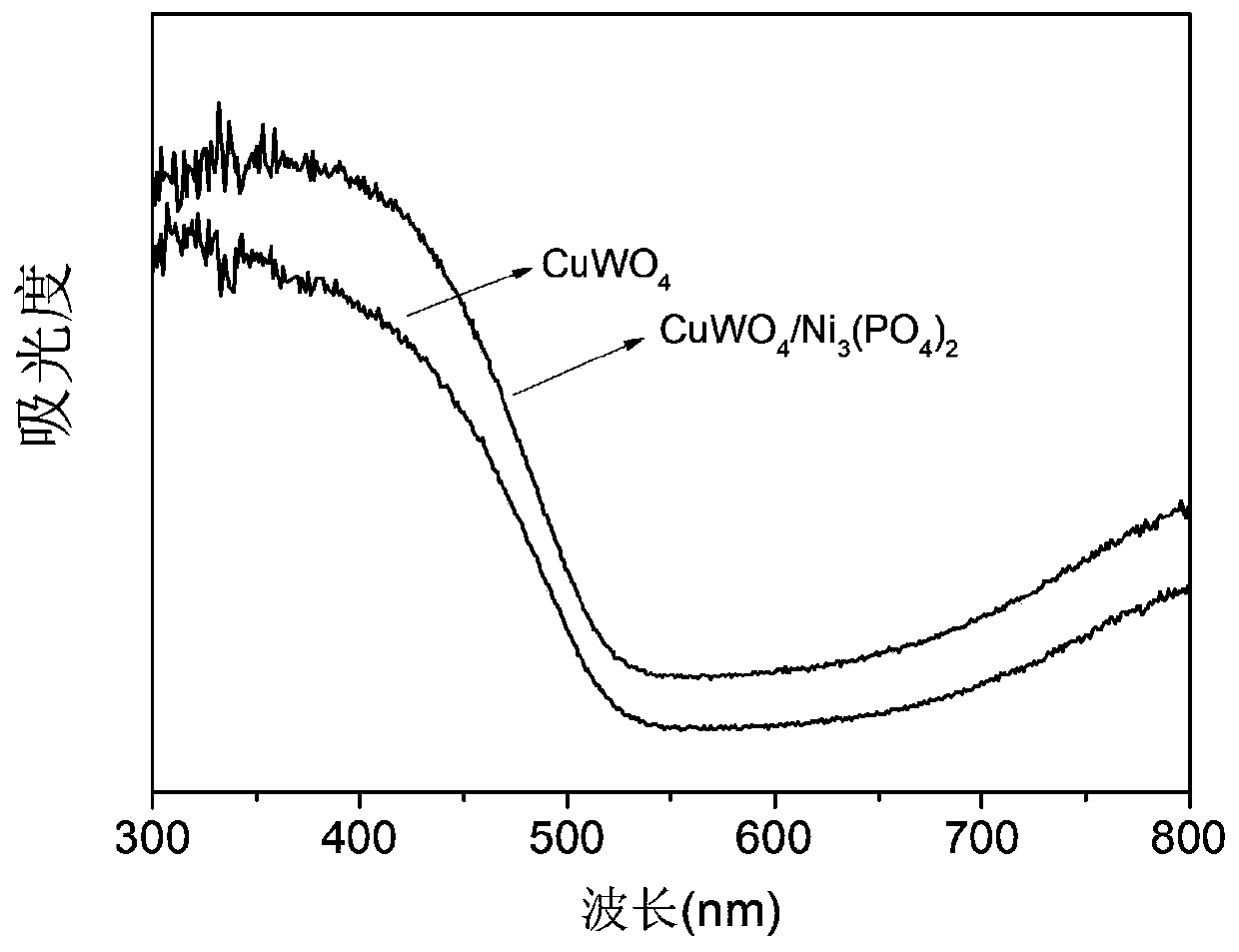

[0022] figure 2 The ultraviolet-visible diffuse reflectance spectra of copper tungstate film electrodes before and after nickel phosphate modification are given. It can be seen that nickel phosphate modification will not change the band edge absorption and band gap value o...

Embodiment 3

[0024] A method for preparing a copper tungstate / nickel phosphate photoanode film with visible light response. The experimental steps are the same as in Example 1. The hydrothermal temperature is changed to 130°C, the hydrothermal time is set to 5h, and copper ions are added dropwise for 3 times; 0.02 Add 1 g of nickel chloride to 100ml of potassium phosphate solution with a concentration of 0.1mol / L to prepare nickel phosphate precipitation, add dropwise 30 μL of nickel phosphate solid dispersion to the surface of copper tungstate electrode, and dry at 100°C to obtain nickel phosphate-modified tungstic acid Copper film electrodes.

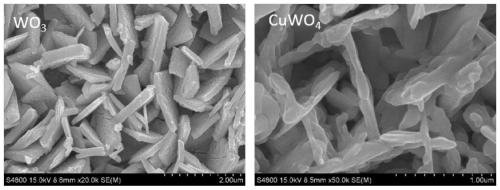

[0025] image 3 The scanning electron microscope images of tungsten trioxide and copper tungstate film electrodes are given. It can be seen that the morphology of hydrothermally synthesized tungsten trioxide is plate-like. These plate-like nanostructures grow vertically on the surface of FTO conductive glass, which can effectively increase the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com