Flexible filamentous spherical porous amorphous nickel phosphate nanoparticles and preparation method thereof

A Nanoparticle, Nickel Phosphate Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of Soft Spherical Porous Amorphous Nickel Phosphate Nanoparticles

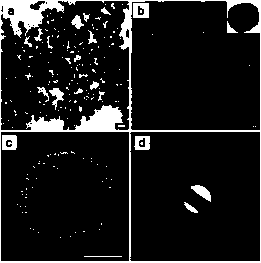

[0029] Under stirring conditions, add 0.1 ml of 2 mol / L sodium dihydrogen phosphate aqueous solution and 0.1 ml of 2 mol / L nickel nitrate aqueous solution to 7 ml of ethylene glycol solution in sequence, after stirring evenly, add 0.16 ml of 5 mol / liter of sodium hydroxide aqueous solution, continue stirring at room temperature for 20 minutes after the dropwise addition, and obtain the transparent precursor solution of light green soft silk spherical nickel phosphate nanoparticles, wherein the concentrations of sodium dihydrogen phosphate, nickel nitrate, and sodium hydroxide are respectively 0.025 mol / liter, 0.025 mol / liter, 0.1 mol / liter; then the prepared precursor solution was reacted at 160 degrees for 1 hour to obtain the following figure 1 The yellow-green colloidal solution shown in a; after natural cooling at room temperature, the nickel phosphate nanoparticle colloidal solution w...

Embodiment 2

[0031] Preparation of Soft Spherical Porous Amorphous Nickel Phosphate Nanoparticles at Different Reaction Temperatures

[0032] Under stirring conditions, add 0.625 ml of 2 mol / L sodium dihydrogen phosphate aqueous solution and 0.625 ml of 2 mol / L nickel nitrate aqueous solution to 47.75 ml of ethylene glycol solution in turn, after stirring evenly, add 1 ml of 5 mol / liter of sodium hydroxide aqueous solution, continue stirring at room temperature for 20 minutes after the dropwise addition, and obtain the transparent precursor solution of light green soft silk spherical nickel phosphate nanoparticles, wherein the concentrations of sodium dihydrogen phosphate, nickel nitrate, and sodium hydroxide are respectively 0.025 mol / L, 0.025 mol / L, 0.1 mol / L; then divide the reaction precursor solution prepared above into four reaction kettles marked A, B, C, and D, and then put the reaction kettles A, B , C, and D were reacted at 120, 140, 160, and 180 degrees Celsius for 1 hour; Co...

Embodiment 3

[0034] Preparation of Soft Spherical Porous Amorphous Nickel Phosphate Nanoparticles at Different Concentrations of Sodium Dihydrogen Phosphate

[0035] Take 4 reaction kettles and mark them as A, B, C, D respectively, then add 7.69 milliliters of ethylene glycol, 0.05 milliliters of 2 mol / liter sodium dihydrogen phosphate aqueous solution, 0.1 milliliter of 2 mol / liter sodium dihydrogen phosphate to A under rapid stirring conditions liter nickel nitrate aqueous solution, and finally add 0.16 ml 5 mol / l sodium hydroxide aqueous solution dropwise; add 7.64 ml ethylene glycol, 0.1 ml 2 mol / l sodium dihydrogen phosphate aqueous solution, 0.1 ml 2 mol / l nickel nitrate solution to B aqueous solution, and finally add 0.16 ml of 5 mol / L sodium hydroxide aqueous solution dropwise; add 7.54 ml of ethylene glycol, 0.2 ml of 2 mol / L sodium dihydrogen phosphate aqueous solution, and 0.1 ml of 2 mol / L nickel nitrate aqueous solution to C, and finally Add 0.16 ml of 5 mol / L sodium hydroxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com