Novel pharmaceutical auxiliary material namely silicified microcrystalline cellulose and preparation method thereof

A technology of microcrystalline cellulose and pharmaceutical excipients, applied in pharmaceutical formulations, medical preparations of non-active ingredients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

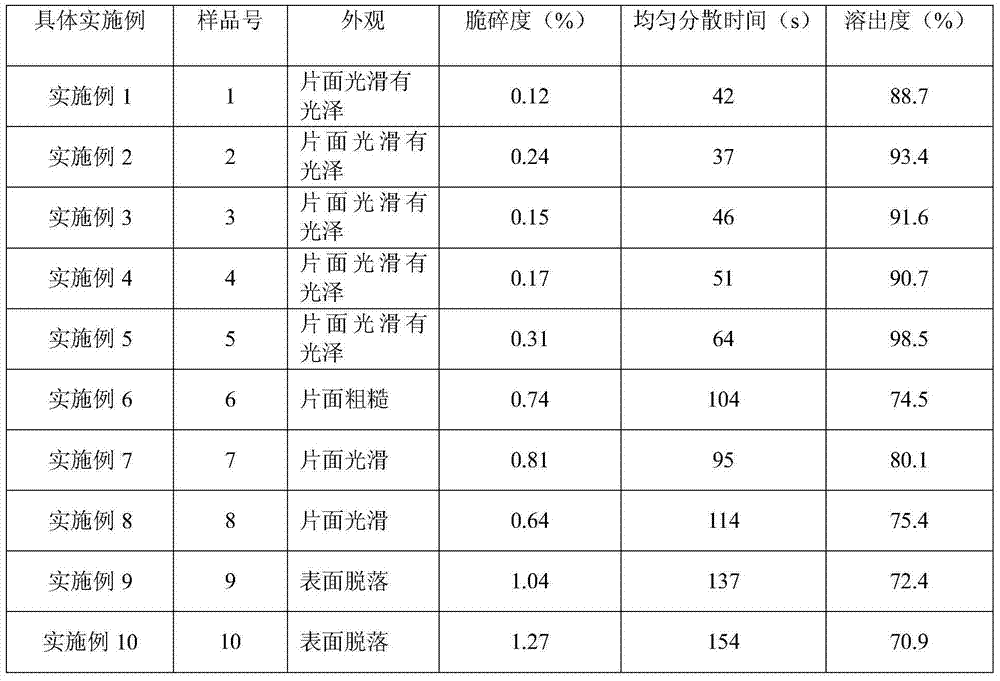

Examples

Embodiment 1

[0019] Components:

[0020] Material name

Proportion(%)

Weight (g)

microcrystalline cellulose

98.15

9815

Micropowder silica gel

1.85

185

[0021] Preparation:

[0022] (1) take by weighing microcrystalline cellulose 9815g and micropowder silica gel 185g of recipe quantity, standby;

[0023] (2) Pass 9815g of microcrystalline cellulose and 154.17g of micropowder silica gel through an 80-mesh sieve for 3 times, add into purified water, stir evenly, and prepare a solution with a solid content of 0.5%, and set aside;

[0024] (3) Add the solution in (2) to the high-shear dispersing homogenizer, set the linear speed to 30m / s, treat it 7 times, and set aside; (4) Add 30.83g of micropowder silica gel to the solution in (3), and stir Evenly, add to the high-shear dispersing homogenizer, set the line speed to 15m / s, process twice, and set aside;

[0025] (5) Put the solution in (4) in the spray dryer, set the air inlet temperat...

Embodiment 2

[0027] Components:

[0028] Material name

Proportion(%)

Weight (g)

microcrystalline cellulose

99.45

9945

Micropowder silica gel

0.55

55

[0029] Preparation:

[0030] (1) microcrystalline cellulose 9945g and micropowder silica gel 55g of prescription quantity are taken by weighing, for subsequent use;

[0031] (2) Pass 9945g of microcrystalline cellulose and 45.83g of micropowder silica gel through an 80-mesh sieve for 3 times, add into purified water, stir evenly, and prepare a solution with a solid content of 4.8% for subsequent use;

[0032] (3) Add the solution in (2) to the high-shear dispersing homogenizer, set the linear velocity to 65m / s, process 5 times, and set aside;

[0033] (4) Add 9.17g of micropowder silica gel to the solution in (3), stir evenly, add it to a high-shear dispersing homogenizer, set the line speed to 18m / s, process 3 times, and set aside;

[0034] (5) Put the solution in (4) in the spray d...

Embodiment 3

[0036] Components:

[0037] Material name

Proportion(%)

Weight (g)

microcrystalline cellulose

99.02

9902

Micropowder silica gel

0.98

98

[0038] Preparation:

[0039] (1) take microcrystalline cellulose 9902g and micropowder silica gel 98g of recipe quantity, standby;

[0040] (2) Pass 9902g of microcrystalline cellulose and 81.67g of micropowder silica gel through an 80-mesh sieve for 3 times, add to purified water, stir evenly, prepare a solution with a solid content of 3.1%, and set aside;

[0041] (3) Add the solution in (2) to a high-shear dispersing homogenizer, set the linear velocity to 50m / s, process it twice, and set aside;

[0042] (4) Add 16.33g of micropowder silica gel into the solution in (3), stir evenly, add it into a high-shear dispersing homogenizer, set the line speed to 22m / s, process it twice, and set aside;

[0043] (5) Put the solution in (4) in the spray dryer, set the inlet air temperature to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com