Refine method of hot metal

A technology for molten iron and refining furnaces, which is used in the improvement of process efficiency, manufacturing converters, metal recovery, etc., can solve the problems of bump boiling, reduction in production volume, and increase in loss of refractory materials in the furnace body, so as to increase the compounding amount and the yield of finished products. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

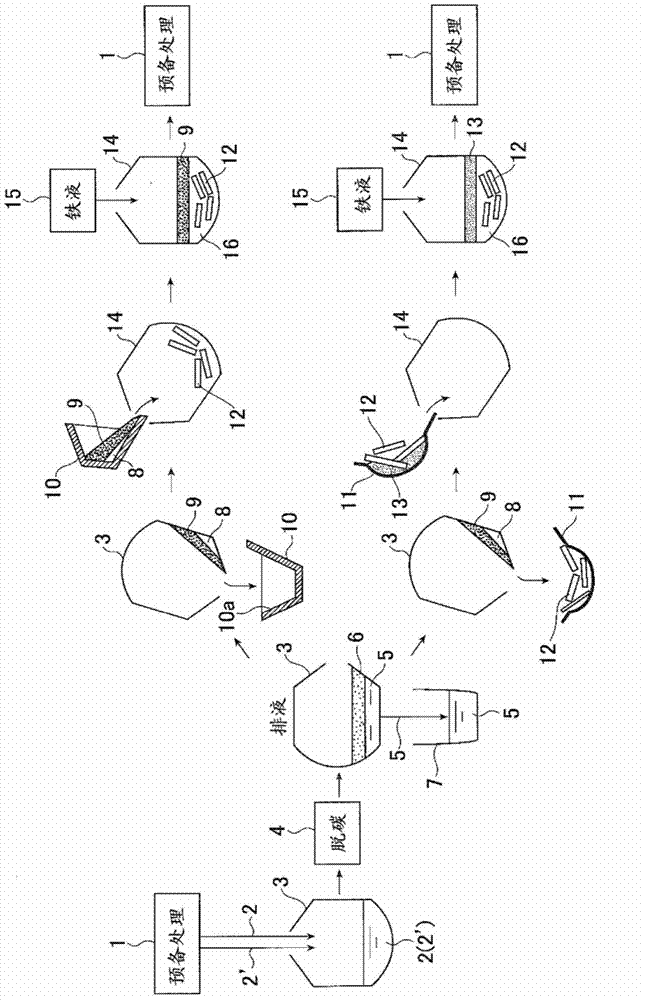

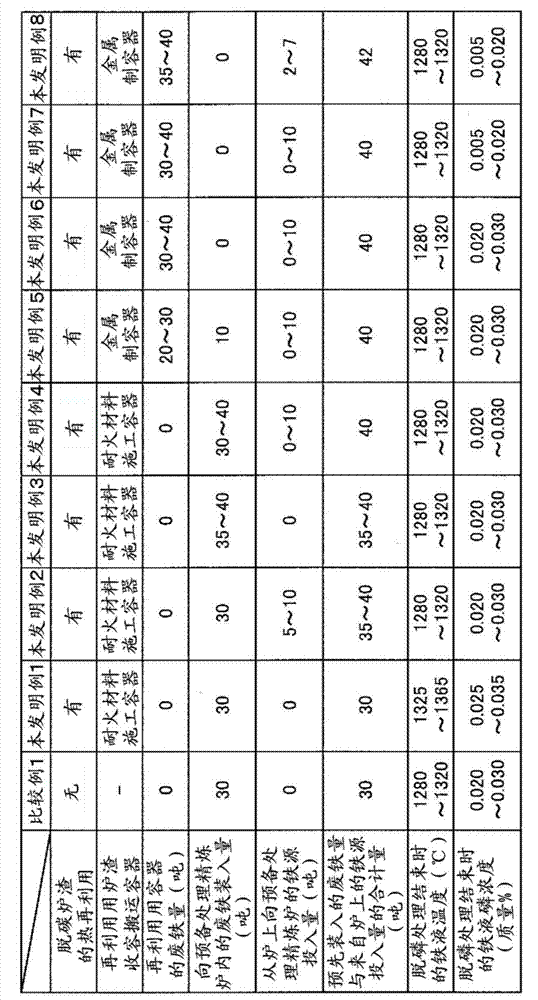

[0063] Hereinafter, the present invention will be described in further detail through examples. according to figure 1 In the shown process flow of the refining method of molten iron of the present invention, the following tests were carried out. In the following test, dephosphorization treatment (desiliconization / dephosphorization treatment) of molten iron that was not desiliconized was implemented in the preliminary treatment refining furnace 14 as a preliminary treatment.

[0064] The low-phosphorus molten iron 2 with a phosphorus concentration of 0.020 mass % is charged into a decarburization refining furnace 3 (converter) with a capacity of 300 tons, and quicklime and dolomite are charged as flux, and argon (Ar Gas) is blown in as a stirring gas and oxygen is supplied from a top blowing lance for decarburization and refining. After the decarburization and refining is completed, the obtained molten steel 5 is discharged to the ladle 7, and the molten steel 5 discharged to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com