A kind of ni-ptfe-sic superhydrophobic anticorrosion coating and preparation method thereof

An anti-corrosion coating, ni-ptfe-sic technology, applied in coatings, electrolytic coatings, etc., can solve the problems of unexplained anti-corrosion effect of super-hydrophobic surface, changes in surface structure and chemical properties, hindering the process of industrial application, etc. Achieve high hardness, improve hydrophobicity, and increase the effect of compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

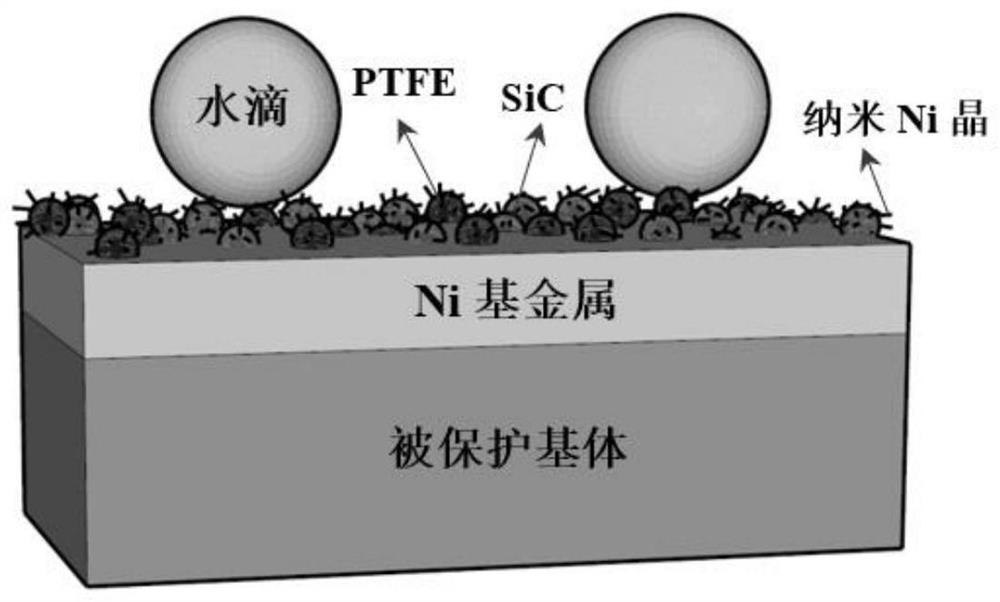

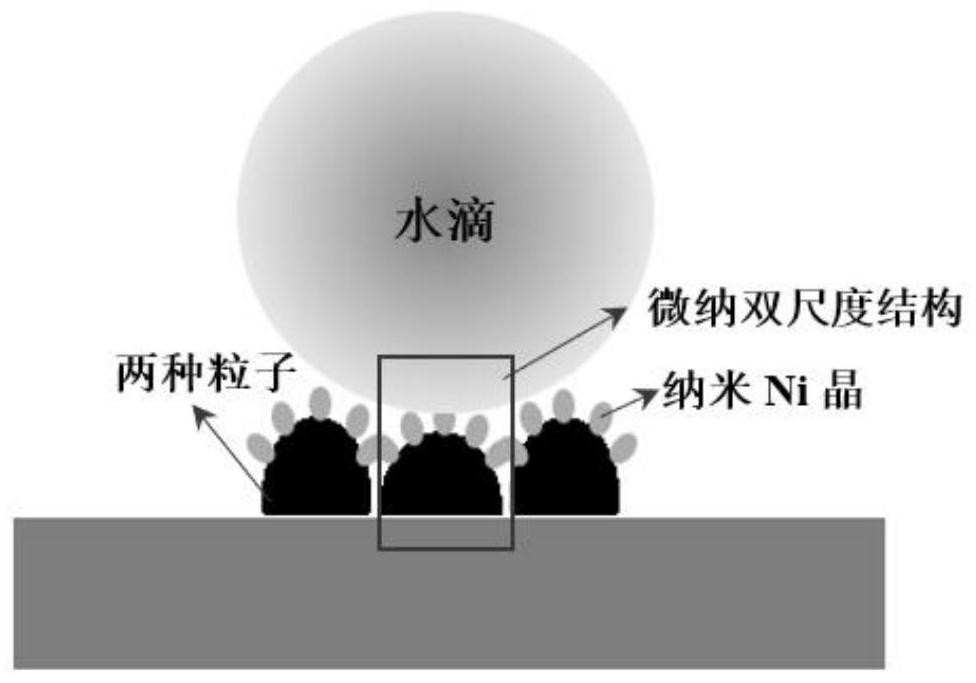

[0032] The invention provides a kind of preparation method of Ni-PTFE-SiC superhydrophobic anticorrosion coating, comprises the following steps:

[0033] Mixing polytetrafluoroethylene nanoparticles, SiC nanoparticles and a nickel-based plating solution to obtain a Ni-PTFE-SiC mixed solution;

[0034] The metal substrate is used as the cathode, the nickel plate is used as the anode, and the Ni-PTFE-SiC mixed solution is used as the plating solution for electrodeposition, and a Ni-PTFE-SiC superhydrophobic anti-corrosion coating is obtained on the surface of the metal substrate.

[0035] The invention mixes polytetrafluoroethylene nanoparticles, SiC nanoparticles and nickel-based plating solution to obtain Ni-PTFE-SiC mixed solution. In the present invention, the average particle size of the polytetrafluoroethylene nanoparticles is preferably 0.7-0.9 μm; the average particle size of the SiC nanoparticles is preferably 0.5-0.7 μm; the solute of the nickel-based plating solution ...

Embodiment 1

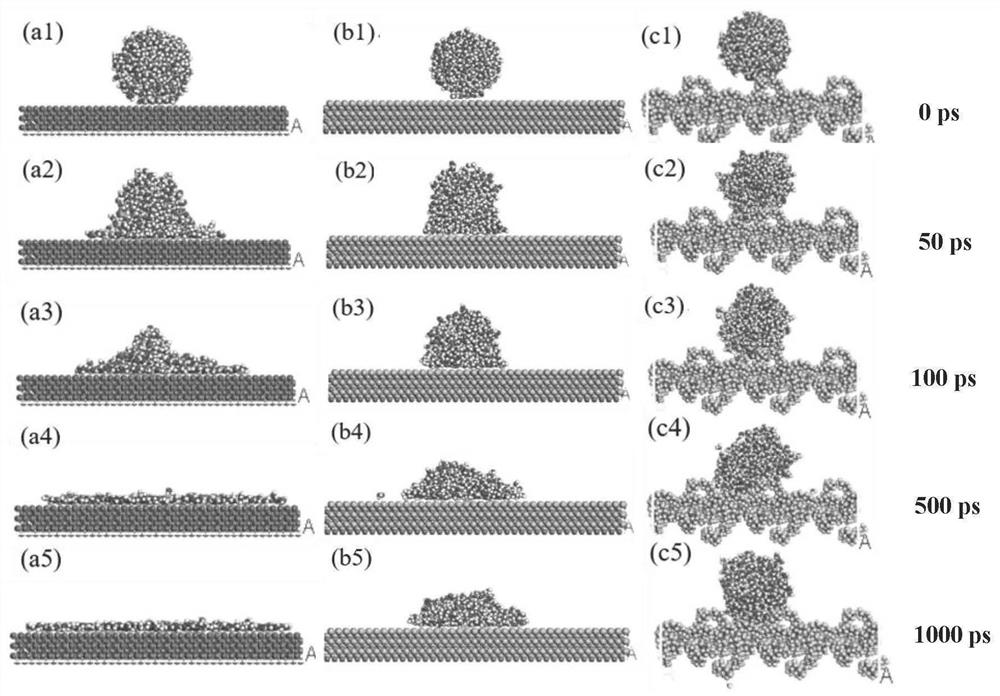

[0051] Molecular dynamics was used to simulate the wetting behavior of water droplets on the surfaces of Ni, PTFE, and SiC to analyze whether the two kinds of nanoparticles embedded in the nickel base were conducive to the improvement of the hydrophobicity of the coating. The specific results are as follows image 3 as shown, image 3 is the wetting process of water droplets on the surface of different materials, where (a1)~(a5) are the wetting process of water droplets on Ni surface, (b1)~(b5) are the wetting process of water droplets on SiC surface, (c1)~ (c5) is the wetting process of water droplets on the surface of PTFE.

[0052] image 3 The results show that: the water molecules on the surface of Ni spread rapidly downwards, and finally form a layer of water film on the surface of the substrate, and the smooth nickel substrate has strong hydrophilicity; when the water droplet is on the surface of SiC, the spreading speed of water molecules is relatively slow. slow, an...

Embodiment 2

[0054] In the electrodeposition process, in order to improve the dispersion of nanoparticles and avoid agglomeration of nanoparticles, a sufficient concentration of surfactant is usually added to improve their dispersion. Compared with PTFE nanoparticles, SiC nanoparticles have a large density. Agglomeration will have an extremely adverse effect on co-deposition. However, the surfactants selected by different preparation processes are different. In order to determine which surfactant has a better dispersion effect on the electrodeposition system of the present invention, molecular dynamics was used to simulate different types of surfactants (hexadecyltrimethyl Ammonium bromide, sodium lauryl sulfate, perfluorooctyl quaternary ammonium iodide) on the dispersion effect of SiC nanoparticles, the results are as follows Figure 4 as shown, Figure 4 is the dispersion of SiC nanoparticles by different surfactants, where (a) is sodium dodecyl sulfate (SDS), (b) is cetyltrimethylammo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com