A kind of sintered valve guide material and its preparation method

A valve guide and sintering time technology, applied in the valve guide related fields, can solve the problems affecting the longevity and safety of the valve guide, the valve guide is prone to wear, and the hardness is insufficient, and achieves easy promotion and use, high hardness, and production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A sintered valve guide material, made of sintered alloy, wherein the sintered alloy has a metallographic structure, which includes: pearlite phase, ferrite phase, pores, Fe-P-C compound phase, Cu-Sn alloy phase or Cu and Cu - the mixed structure of the Sn alloy phase and the dispersed graphite phase accounting for 1-2% of the mass ratio of the sintered alloy, and the at least one solid lubricant, the lubricant is distributed in the pores or the grain boundaries of the sintered alloy metallographic structure .

[0018] Among them, on the cross-section of the metallographic structure of the sintered alloy, the pearlite phase accounts for 50-85% of the matrix area, the Fe-P-C compound phase accounts for 8-25% of the cross-sectional area of the metallographic structure, and the Cu-Sn alloy phase or Cu The mixed structure with Cu-Sn alloy phase accounts for 0.5-3% of the cross-sectional area of the metallographic structure.

[0019] A preparation method of a sintered va...

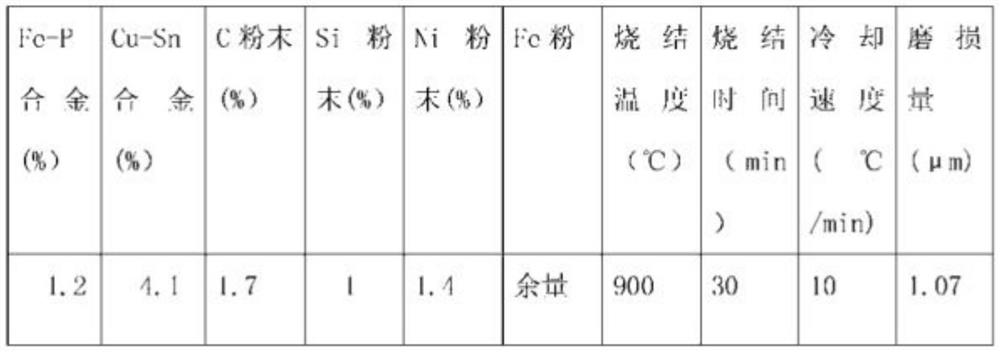

Embodiment 2

[0026] It is basically the same as that of Example 1, furthermore, a preparation method of sintered valve guide material, the preparation method has the following steps:

[0027] A powder mixture was prepared, by mass, which included 1.2% Fe-P alloy powder, 4.1% Cu-Sn alloy powder, 1.7% C powder, 1% Si powder, 1.4% Ni powder and the balance Fe powder ; Wherein, Fe-P powder powder is made up of 16% phosphorus, unavoidable impurity and remainder iron; Cu-Sn alloy powder is made up of 10% tin, unavoidable impurity and remainder copper;

[0028] compressing the powder mixture in the tubular lumen, the powder mixture forms a tubular compact;

[0029] Then the tubular compacted body is sintered in a non-oxidizing atmosphere at a sintering temperature of 900°C;

[0030] Wherein the sintering time is 30 minutes;

[0031] The sintered body obtained by sintering is cooled at a cooling rate of 10° C. / minute or more.

[0032] The obtained valve guide was subjected to a wear test on a w...

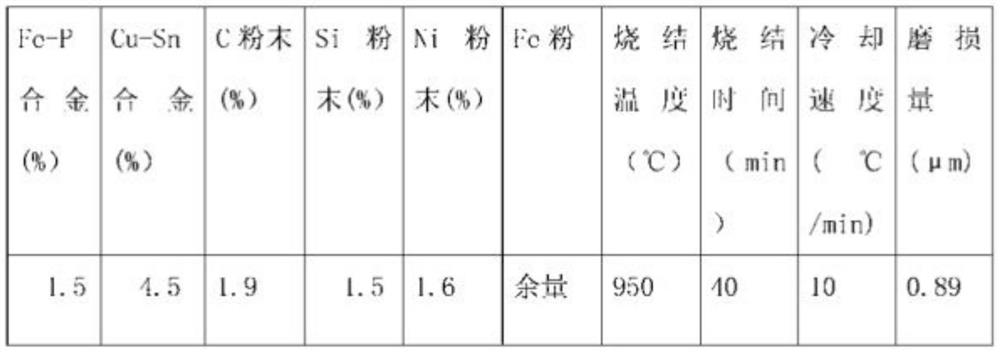

Embodiment 3

[0037] It is basically the same as that of Example 1, furthermore, a preparation method of sintered valve guide material, the preparation method has the following steps:

[0038] A powder mixture was prepared, by mass, which included 1.5% Fe-P alloy powder, 4.5% Cu-Sn alloy powder, 1.9% C powder, 1.5% Si powder, 1.6% Ni powder and the balance Fe powder ; Wherein, Fe-P powder powder is made up of 16% phosphorus, unavoidable impurity and remainder iron; Cu-Sn alloy powder is made up of 10% tin, unavoidable impurity and remainder copper;

[0039] compressing the powder mixture in the tubular lumen, the powder mixture forms a tubular compact;

[0040] Then the tubular compacted body is sintered in a non-oxidizing atmosphere at a sintering temperature of 950°C;

[0041] Wherein the sintering time is 40 minutes;

[0042] The sintered body obtained by sintering is cooled at a cooling rate of 10° C. / minute or more.

[0043] The obtained valve guide was subjected to a wear test on a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com