rubber laminate

一种橡胶层、合体的技术,应用在橡胶层状产品、分层产品、机械设备等方向,能够解决不良率增加、氟橡胶硫化粘合性差、氟橡胶成本高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

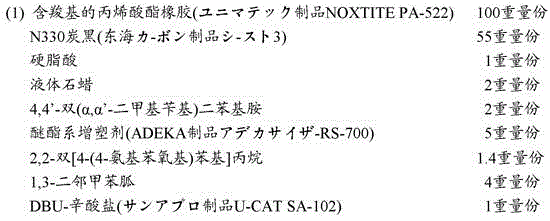

Embodiment 1

[0046]

[0047] The above-mentioned components were kneaded using an 8-inch roll, and then an unvulcanized sheet with a thickness of 3 to 4 mm was produced.

[0048]

[0049] The above-mentioned components were kneaded using an 8-inch roll, and then an unvulcanized sheet with a thickness of 3 to 4 mm was produced.

[0050] (3) Overlay the unvulcanized sheet formed by the above-mentioned carboxyl group-containing acrylate rubber composition with the unvulcanized sheet formed by the polyol crosslinkable fluororubber composition, at a temperature of 160° C., a surface pressure of 10 MPa, and a time of 30 minutes. Under these conditions, press molding is carried out, followed by open vulcanization (secondary vulcanization) at 175°C for 4 hours to form an acrylic rubber / fluororubber laminate.

[0051] A sample (15×100×5 mm) obtained by shearing the obtained rubber laminate was subjected to a peeling test (peeling speed: 50 mm / min) in accordance with JIS K6256, and measurement...

Embodiment 2

[0054] In Example 1, the amount of 1,3-di-o-tolylguanidine was changed to 6 parts by weight and used.

Embodiment 3

[0056] In Example 1, an equivalent amount (1 part by weight) of DBU-toluenesulfonate (U-CATSA506, manufactured by Sunapro) was used instead of DBU-octanoate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com