Preparation method for oxidized graphene/water-soluble polyurethane composite material

A technology of water-soluble polyurethane and composite materials, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve problems such as low strength and poor performance, and achieve good strength of finished products, novel design and controllability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The concrete steps of the preparation method of the graphene oxide / water-soluble polyurethane composite material involved in this implementation are:

[0015] (1) Graphite powder pretreatment process: get 55ml mass fraction and be the concentrated sulfuric acid of 98%, 8g potassium persulfate and 8g phosphorus pentoxide mix uniformly and be heated to 80 ℃ until completely dissolving to form mixed solution, get 16g graphite powder in 400 Add to the mixture at a stirring speed of ~500r / min, and continue to stir at 20-25°C for 6 hours to oxidize the above mixture. After the oxidation is completed, dilute the mixture with 500ml of distilled water and wash it with suction to neutrality (PH=7 ), then vacuum-dried at 35 to 45°C for 4 hours to obtain graphite powder;

[0016] (2) Oxidation treatment process: Take 16g of graphite powder prepared in step (1) and 450ml of concentrated sulfuric acid with a mass fraction of 98% and a temperature of 0°C and mix them in an ice bath at...

Embodiment 2

[0021] In this embodiment, according to the preparation method described in Example 1, in step (4), add 7.5g, 15g, 22.5g and 30g of graphene oxide aqueous phase dispersion prepared in step (3) to 100g water-soluble polyurethane respectively solution to prepare graphene oxide / water-soluble polyurethane composite samples with a solid content of 0.25%, 0.5%, 0.75% and 1%, and then cut the prepared samples for strength tensile testing on a tensile tester. stretch test.

Embodiment 3

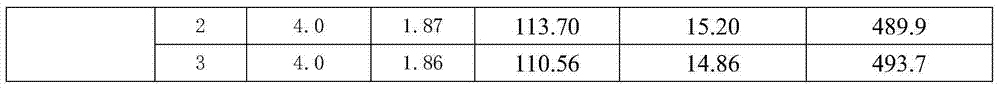

[0023] In the present embodiment, the water-soluble polyurethane composite material whose mass fraction of graphene oxide after drying is 0% is taken as a comparative example, and the quality of graphene oxide after drying respectively prepared in Example 2 is tested with a universal tester in the prior art. The graphene oxide / water-soluble polyurethane composite material samples with fractions of 0.25%, 0.5%, 0.75% and 1% were subjected to tensile strength test and elongation test. During the test, each group of samples was made into a width of 4mm and a thickness of 1.5mm. -2mm film, the specific data are shown in Tables 1 and 2:

[0024]

[0025]

[0026] Table 1

[0027]

[0028] Table 2

[0029]Above-mentioned experimental data shows, the graphene oxide / water-soluble polyurethane composite material prepared by the preparation method of the graphene oxide / water-soluble polyurethane composite material researched and designed by the present invention has good tensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com