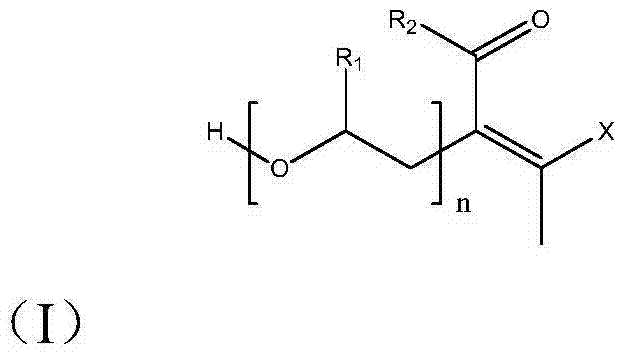

Novel polyetheramine used as a gasoline detergent and a synthetic method thereof

A gasoline detergent and polyetheramine technology, applied in the field of new polyetheramine and its synthesis, can solve the problems of limited application and high stability, and achieve the effects of good selectivity, improved dynamic performance and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0033] Add 10 kilograms of polypropylene glycols (molecular weight 1000), 1 kilogram of acetylacetone, 20 kilograms of toluene and 6.2 grams of DMAP composite catalysts in the 100 liters of reactors that water separator and condensation pipe are housed, stir 4 hours at 25 ℃ earlier, then stir Slowly heated to reflux (~110°C), and the generated water was carried out by toluene. When no water was formed, the reaction was stopped and the temperature was lowered to 70°C.

[0034] Add 0.6 kg of ethylenediamine to the above reaction system, and slowly heat it to reflux (~110°C) under stirring. The generated water is carried out by toluene. Low boiling substances such as toluene were removed under reduced pressure at ℃ to obtain 11.8 kg of the product polyetheramine.

example 2

[0036] Add 10 kilograms of polypropylene glycols (molecular weight 1000), 1.16 kilograms of methyl acetoacetate, 20 kilograms of dimethylbenzene and 3.5 gram imidazole composite catalysts in 100 liters of reactors that water trap and condensation pipe are housed, first 25 ℃ of stirring 4 hours, Then slowly heated to reflux (~140°C) under stirring, the generated water was carried out by xylene, and when no water was formed, the reaction was stopped and the temperature was lowered to 70°C.

[0037] Add 0.6 kg of ethylenediamine to the above reaction system, and slowly heat it to reflux (~140°C) under stirring. The generated water is carried out by xylene. Low boilers such as xylene were removed under reduced pressure at 100°C to obtain 12.1 kg of the product polyetheramine.

example 3

[0039] Add 20 kilograms of polypropylene glycols (molecular weight 2000), 1 kilogram of acetylacetone, 40 kilograms of toluene and 6.2 grams of DMAP composite catalysts in the 100 liters of reactors that water trap and condensation pipe are housed, stir 4 hours at 25 ℃ earlier, then stir Slowly heated to reflux (~110°C), and the generated water was carried out by toluene. When no water was formed, the reaction was stopped and the temperature was lowered to 70°C.

[0040] Add 0.86 kg of piperazine to the above reaction system, and slowly heat it to reflux (~110°C) under stirring, the generated water is carried out by toluene, and when anhydrous is formed, the vacuum degree is 0.1MPa, and the temperature range is 60~100°C Low boilers such as toluene were removed under reduced pressure to obtain 21.9 kg of the product polyetheramine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com