A selective laser sintering molding method for a heat-conducting functional material

A functional material and selective technology, which is applied in the field of selective laser sintering of thermally conductive functional materials, can solve the problems of complex process, damage to the original shape, high cost, etc., and achieve the effect of simple process and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Disperse 100g KH550 (γ-aminopropyltriethylsilane) in a mixed solution of 5000mL ethanol and water with a mass ratio of 1:1, and then add 20kgAl 2 o 3 The powder (particle size is 3 μm), after being fully stirred, placed in a constant temperature drying oven, first dried at 70 ° C for 2 h, and then dried at 110 ° C for 6 h to obtain the coupled Al 2 o 3 Powder;

[0030] (2) Dry the nylon 12 (PA12) pellets at 80°C, then weigh 16kg of the coupled Al 2 o 3Put the powder and 4kg of dried nylon 12 granules in a mixer, stir for 10 minutes at 1000rpm, and then put them in a twin-screw extruder at 220°C and 240rpm to extrude twice for granulation. Obtain composite pellets;

[0031] (3) The composite granular material prepared according to step (2) is pulverized under the condition of liquid nitrogen cooling, after pulverization, crosses a 120 mesh sieve, and the material on the sieve is pulverized again, and the fine powder under the sieve is a composite thermally condu...

Embodiment 2

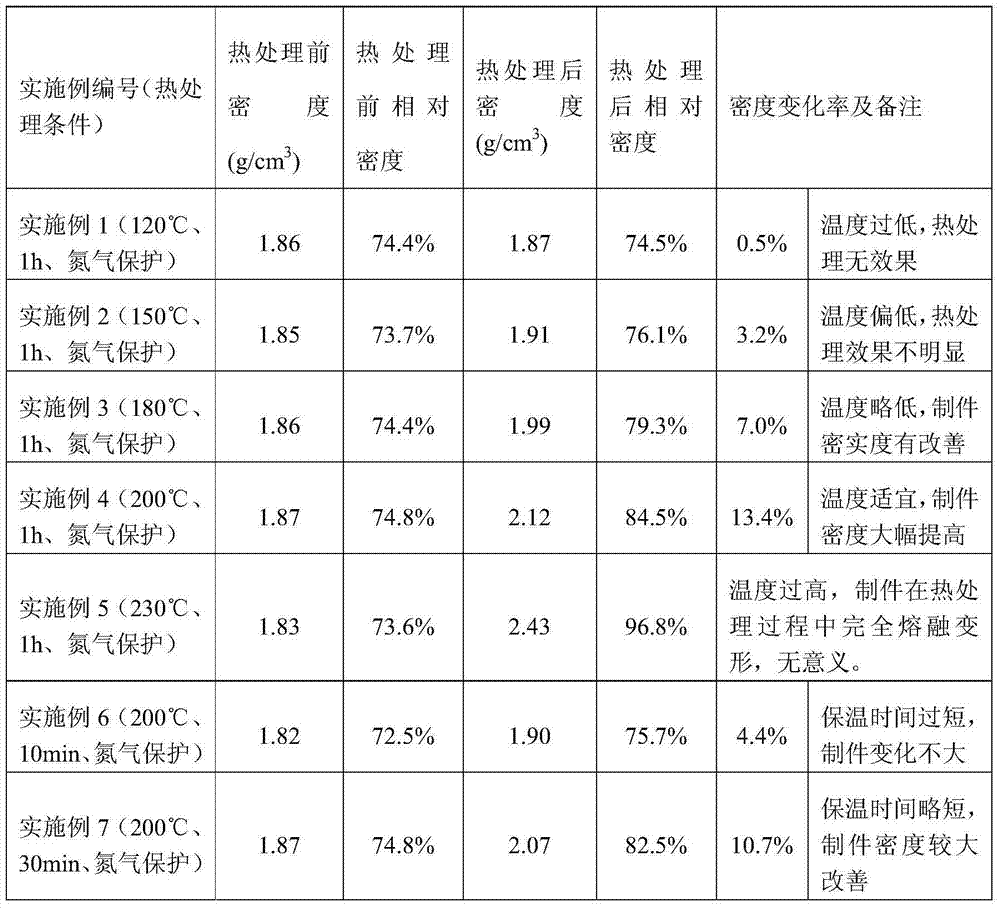

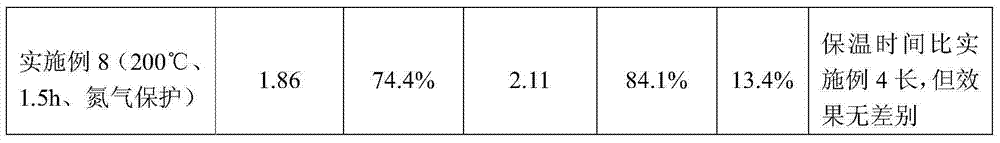

[0035] The method is the same as in Example 1, except that in step (5), the heat treatment temperature is 150° C., and it is incubated for 1 hour; the density after the heat treatment is tested with the Archimedes method density balance, and the density change before and after the heat treatment is compared, and the heat treatment is calculated. The density change rate of the sample under temperature and time, the specific data are shown in Table 1.

Embodiment 3

[0037] The method is the same as in Example 1, the difference is that in step (5), the heat treatment temperature is 180°C, and the heat preservation is carried out for 1h; the density after the heat treatment is tested with the Archimedes method density balance, and the density change before and after the heat treatment is compared, and the heat treatment is calculated. The density change rate of the sample under temperature and time, the specific data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com