Edible fungi bag cultivation technology based on natural rain simulation

A technology of edible fungi and mycelium, applied in cultivation, application, plant cultivation, etc., can solve the problems of lack of edible fungi in the "rain" stage, edible fungus cultivation not in water conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

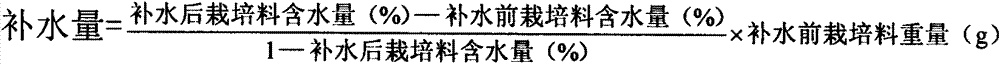

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: Pleurotus ostreatus cultivation method

[0019] (1) Bacteria bag preparation

[0020] Medium formula: corn cob 48%, cottonseed husk 40%, bran 4%-5%, superphosphate 1%, plant ash 1%-2%, urea 0.3%-0.5%, lime 2%-3%.

[0021] Mixing material bagging: Stir the main material and water-insoluble auxiliary materials evenly; prepare soluble materials into an aqueous solution, add them gradually, and mix well. According to the ratio of material to water 1: 0.9-1, add water and mix the material, adjust the water content to about 55% and the pH value to 7.5-8. Choose a 50x25x0.05 cm polyethylene plastic tube for loading, compact it while loading (about 2.5 kg of dry material per bag), and tie the two ends tightly with ropes.

[0022] Sterilization and inoculation: Sterilize at normal pressure, the temperature reaches 100°C, keep for 8-10 hours, then simmer for 8-10 hours after the fire is stopped. After being out of the pot, the temperature of the material is coole...

Embodiment 2

[0026] Embodiment 2: Flammulina velutipes cultivation method:

[0027] (1) Bacteria bag preparation

[0028] Medium formula: 70% to 80% of cottonseed hulls, 15% to 20% of bran, 3% to 5% of corn flour or soybean flour, 1% each of sugar and gypsum, 2% each of superphosphate and lime powder.

[0029] Mixing material bagging: Stir the main material and water-insoluble auxiliary materials evenly; prepare soluble materials into an aqueous solution, add them gradually, and mix well. According to the ratio of material to water 1: 0.9-1, add water and mix the material, adjust the water content to about 55% and the pH value to 7.5-8. Take a polypropylene plastic bag with a length × width of 35 × 17 cm and put it into the bag after mixing the materials evenly. The filling capacity is about 50% of the bag volume. Each bag contains 750g of wet material, and the upper end of the fungus bag is tied tightly with a rope. . Sterilization and inoculation: Sterilize at normal pressure, the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com