Glass welded double-vacuum-layer metal vacuum composite plate and production method thereof

A double vacuum, composite panel technology, applied in building components, thermal insulation, sound insulation and other directions, to achieve the effect of improving heat insulation, less cost and process, saving manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

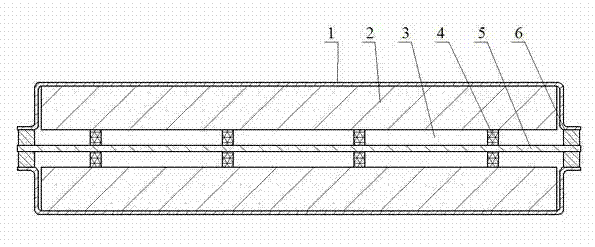

[0036] Embodiment 1: see figure 1 , the glass-welded double-vacuum-layer metal vacuum composite board is composed of a shell 1, a core plate 2, a vacuum chamber 3, a support 4 and a partition 5, the shell 1 is made of a low-carbon steel plate with a thickness of 0.3-1.0mm; the core plate 2 is Metal plate, ceramic plate, glass plate, plastic plate or composite plate, etc., preferably 1-2mm thick aluminum alloy plate or 3-5mm thick tempered glass plate, etc.; the partition 5 can be made of low-carbon steel plate, which is directly welded to the shell 1 Together, the vacuum chamber 3 forms two independent vacuum layers; the support 4 is made of metal, ceramics, glass or polymer, and is distributed on the partition in a lattice by printing, printing, spraying, mechanical placement, etc. On the upper and lower surfaces of 5, the supporting height of the support 4 is preferably 0.15-1.0 mm, and the diameter of the supporting point is preferably 0.3-1.0 mm. The manufacturing method ...

Embodiment 2

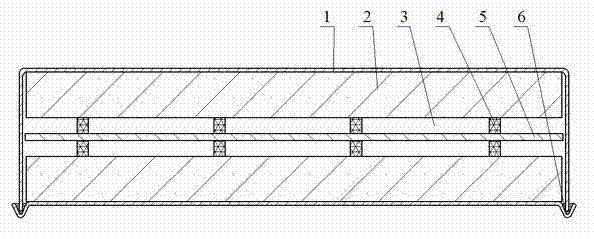

[0037] Example 2: See Example 1 and figure 2 , which is basically the same as in Example 1, except that the separator 5 is made of an aluminum alloy plate and placed directly in the vacuum chamber 3, and the low-carbon steel plate forming the shell 1 is directly punched out of a sealing groove for edge sealing during stamping and forming, sealing Glass solder is placed in the groove.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com