Method and system for extracting part of crude oil from high-oil-content nut jam mud

A technology for extracting part and nut butter, which is applied in the direction of edible oil/fat, fat oil/fat production, fat production, etc., can solve the problems of low loss rate of crude oil, oil and seed meal can not be used at the same time, and achieve easy preservation, nuts High utilization rate and strong fragrance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

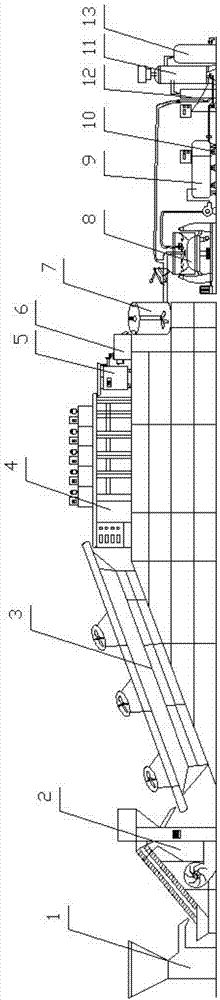

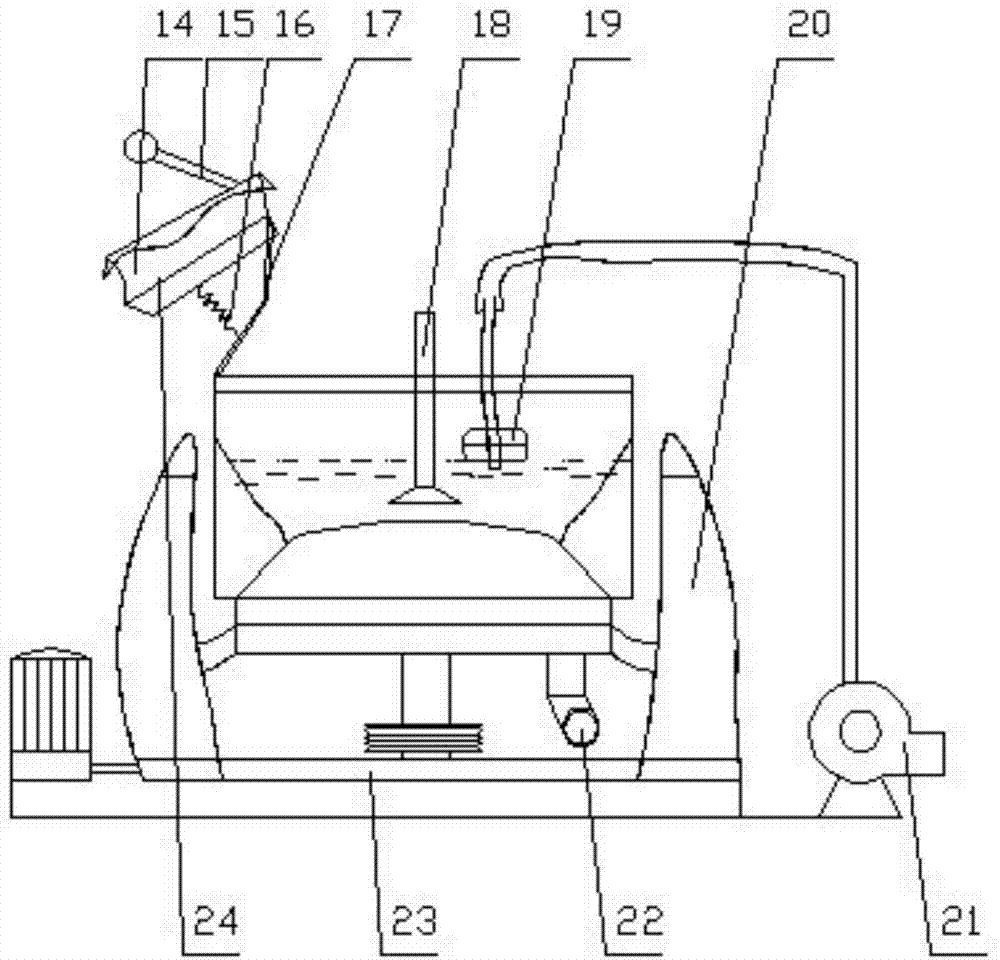

[0041] A method for extracting part of crude oil from high-oil walnut puree, the steps are as follows:

[0042] (1) Storage: Pour 50kg of peeled walnut kernels into the storage hopper, and the walnut kernels enter the conveyor belt of the winnowing machine at a constant speed (the transmission speed of the conveyor belt is 0.01-0.03m / s);

[0043] (2) Wind selection: remove dust, stones, metal shavings or other impurities mixed in walnut kernels by wind separation machine;

[0044] (3) Air-drying: walnut kernels are air-dried through an air-drying conveyor belt;

[0045] (3) Baking: After the walnut kernels pass through the winnowing machine, they enter the baking tunnel, the baking temperature is 90°C, and the baking time is 5-20 minutes;

[0046] (4) Pulverization: in order to improve the efficiency of stone roller grinding process, walnut kernel is carried out preliminary pulverization with mincer, obtains walnut meal;

[0047] (5) Grinding: the walnut meal is ground once ...

Embodiment 2

[0054] A method for extracting part of the crude oil from high oily pine nut puree, the steps are as follows:

[0055] (1) Storage: Pour 50kg of pine nut kernels into the storage hopper, and the pine nut kernels enter the air separator conveyor belt at a constant speed (the transmission speed of the conveyor belt is 0.01-0.03m / s);

[0056] (2) Wind selection: remove the dust, stones, metal shavings or other impurities mixed in the pine nuts by wind selection machine;

[0057] (3) air-drying: the pine nuts are air-dried through the air-drying conveyor belt;

[0058] (3) Roasting: After the pine nuts pass through the winnowing machine, they enter the baking tunnel, the baking temperature is 120°C, and the baking time is 5-20 minutes;

[0059] (4) Pulverization: in order to improve the efficiency of the stone roller grinding process, use a grinder to carry out preliminary pulverization to the pine nut kernel to obtain the pine nut meal;

[0060] (5) Grinding: the pine nut meal ...

Embodiment 3

[0067] A method for extracting part of the crude oil from high oily pine nut puree, the steps are as follows:

[0068] (1) Storage: Pour 50kg of pine nut kernels into the storage hopper, and the pine nut kernels enter the conveyor belt of the winnowing machine at a constant speed (the transmission speed of the conveyor belt is 0.01-0.03m / s);

[0069] (2) Wind selection: remove the dust, stones, metal shavings or other impurities mixed in the pine nuts by wind selection machine;

[0070] (3) air-drying: the pine nuts are air-dried through the air-drying conveyor belt;

[0071] (3) Roasting: After the pine nuts pass through the winnowing machine, they enter the baking tunnel, the baking temperature is 140°C, and the baking time is 5-20 minutes;

[0072] (4) Pulverization: in order to improve the efficiency of the stone roller grinding process, use a grinder to carry out preliminary pulverization to the pine nut kernel to obtain the pine nut meal;

[0073] (5) Grinding: the pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com