Sodium bismuth titanate-barium titanate lead-free transparent electro-optic ceramic and preparation method thereof

A technology of sodium bismuth titanate and electro-optical ceramics is applied in the field of sodium bismuth titanate-barium titanate lead-free transparent electro-optical ceramics and its preparation, which can solve the problems of opacity of ceramics, difficult to control volatilization, long sintering time, etc., and achieve inhibition and elimination Air holes, high electro-optic coefficient, the effect of suppressing the generation of impurity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

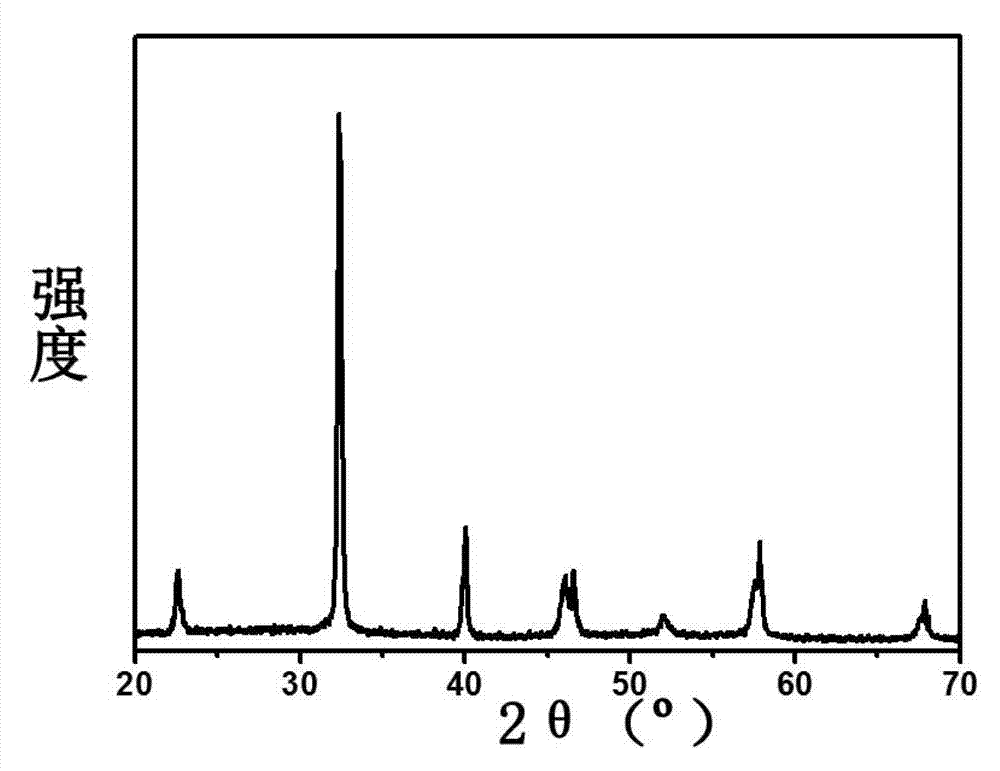

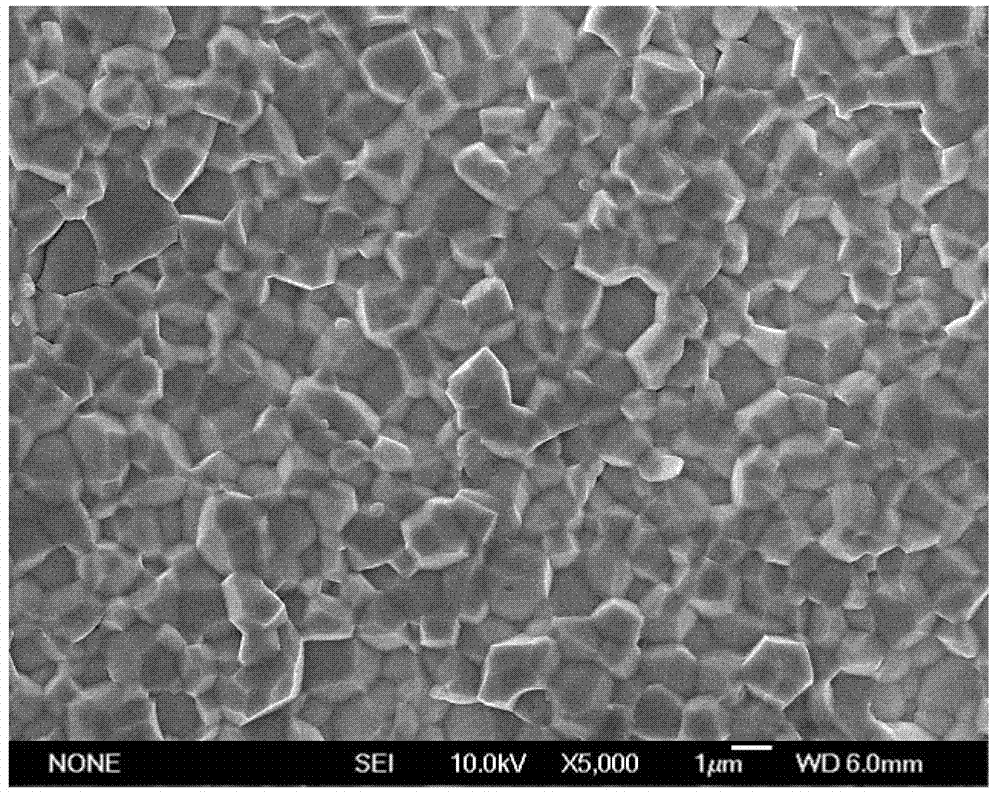

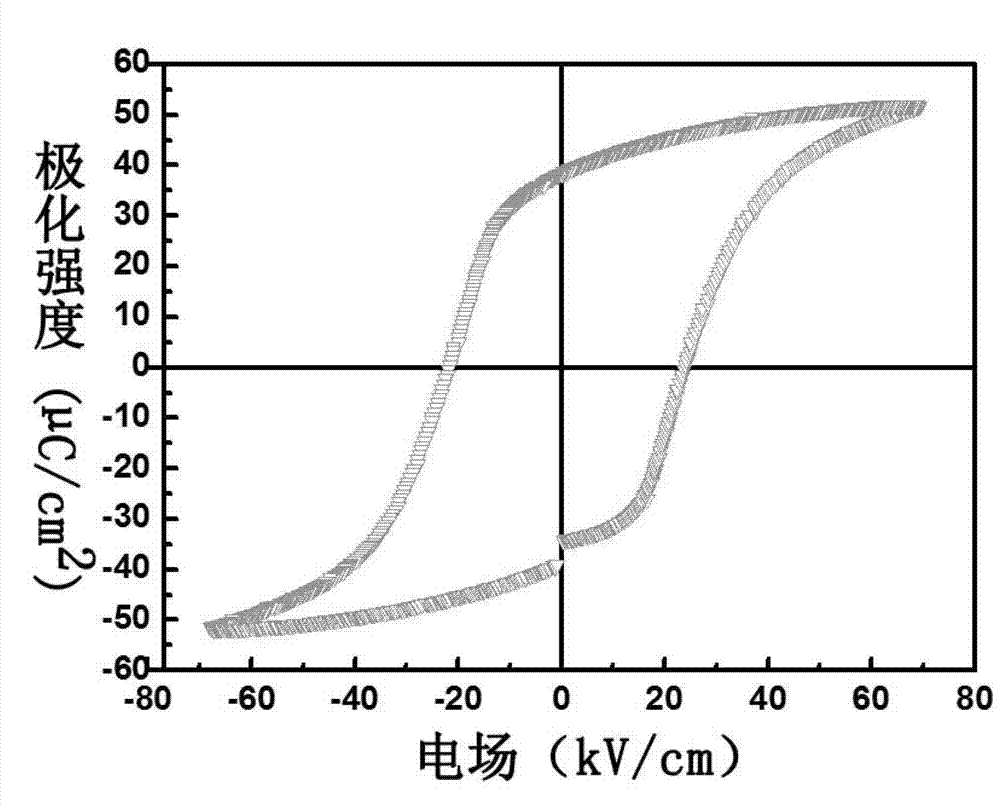

[0031] The invention provides a preparation method of bismuth sodium titanate-barium titanate lead-free transparent electro-optic ceramics, the chemical composition of the bismuth sodium titanate-barium titanate lead-free transparent electro-optic ceramics is (1-x)(Na 0.5 Bi 0.5 )TiO 3 -xBaTiO 3 , where 0.05≤x≤0.08. The preparation method adopts an oxygen-flowing-hot-pressing sintering process, controls the powder synthesis and sintering technology, suppresses the formation of impurity phases and eliminates pores, and achieves the purpose of improving the optical transmittance and electro-optic effect of the material. Specifically, as an example, the preparation method of the present invention may include the following steps.

[0032] (1) Ingredients: using Na 2 CO 3 、 Bi 2 o 3 、TiO 2 、BaCO 3 As raw materials, each raw material powder is accurately weighed according to the chemical composition of the above sodium bismuth titanate-barium titanate lead-free transparent ...

Embodiment 1

[0051] Press (1-x)(Na 0.5 Bi 0.5 )TiO 3 -xBaTiO 3 , where x=0.06 ingredients, using φ2mm ZrO 2 The mixed ball is used as the ball milling medium for planetary ball milling for 6 hours, and after drying, the raw material obtained is ground into powder, and then passed through a 200-mesh sieve to keep the components uniform. After sieving, the powder is put into an alumina crucible and pre-fired at 850°C for 2 hours to synthesize. After the synthesis, the powder is crushed through a 100-mesh sieve, planetary ball milled for 4 hours, then dried and added with a mass concentration of 6% PVA binder, and formed The pressure is 300MP, the forming mold is a cylinder of φ20×15, and then sintered by oxygen-hot pressing. The parameters of the sintering process are: the temperature rise rate is 200°C / hour from room temperature to 900°C, and the temperature is kept for 1 hour; then 100°C ℃ / hour to heat up, and gradually increase the pressure to 250MPa, then keep the pressure constant, ...

Embodiment 2

[0053] Press (1-x)(Na 0.5 Bi 0.5 )TiO 3 -xBaTiO 3 , where x=0.05, ingredients, using φ2mm ZrO 2 The mixed ball was used as the ball milling medium for ball milling for 5 hours. After drying, the obtained raw material was ground into powder, and then passed through a 200-mesh sieve to keep the components uniform. After sieving, the powder is put into an alumina crucible and pre-fired at 850°C for 3 hours to synthesize. After the synthesis, the powder is crushed through a 100-mesh sieve and ball milled for 4 hours. Add a PVA binder with a mass concentration of 6%. The molding pressure is 350MPa. The molding mold is The φ20×15 cylinder is then sintered by oxygen-hot pressing. The parameters of the sintering process are: the temperature rises from room temperature to 830°C at a rate of 200°C / hour, and the temperature is kept for 1 hour; then the temperature is raised at 100°C / hour, and Gradually increase the pressure to 240MPa, then keep the pressure constant, heat up to 1000°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com