A high-precision deep-hole grinding mandrel with a plastic grinding body

A grinding body and high-precision technology, applied in the direction of grinding tools, etc., can solve the problems of large cylindricity error, waste of resources, and low efficiency of the grinding body, and achieve the effects of improving production efficiency, saving processing costs, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

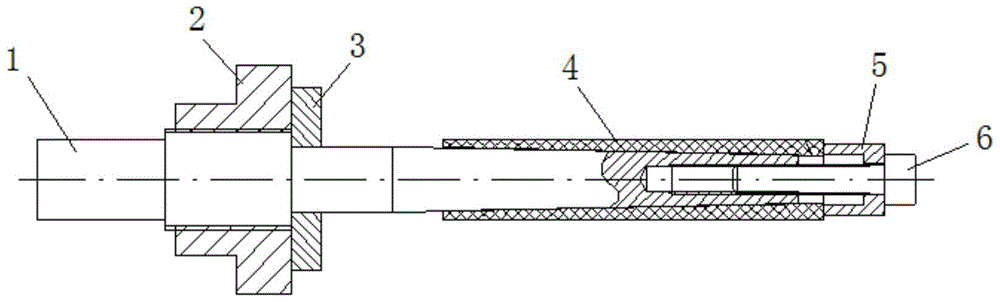

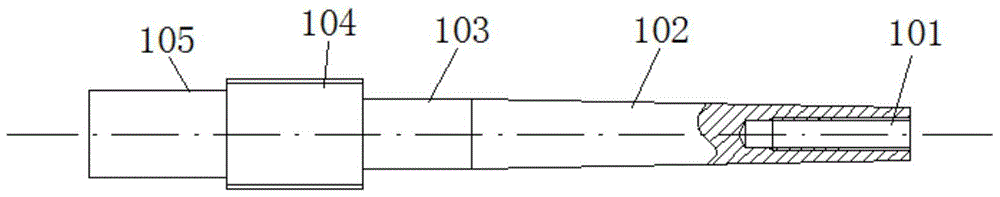

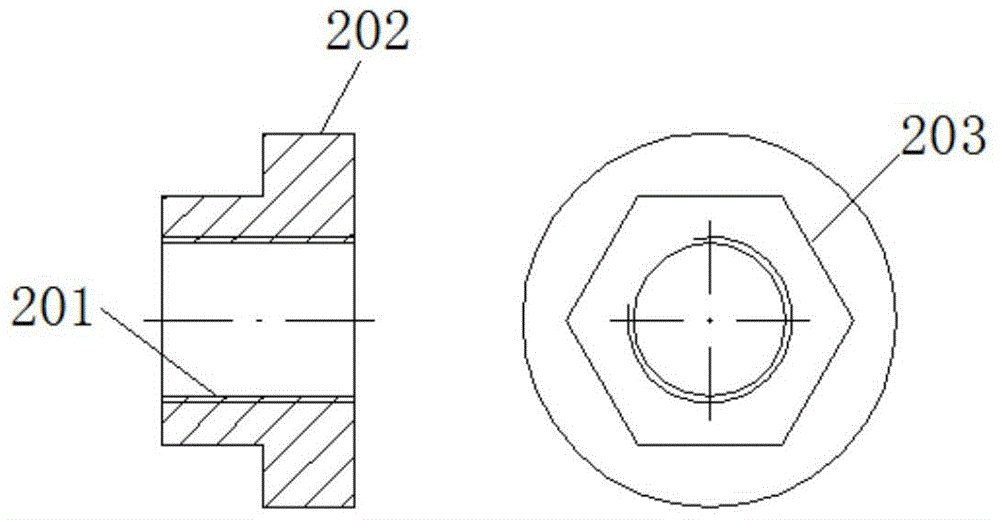

[0019] Take the tapered mandrel 1 as the basic component of assembly, screw the adjusting nut 2 into the external thread section 102 on the tapered mandrel 1, assemble the ejector washer 3 into its transition section 103 and make it fit the external thread The end face of the section 1-3, the inner cone plastic grinding body 4 is assembled into its outer cone segment 102, the pressing surface 504 on the accessory adjustment top cap 5 is close to the end face at the small cone hole of the plastic grinding body 4, through The inner hexagon screw 6 is screwed into the inner screw hole 101 at the end of the outer cone section 102. After the inner hexagon screw 6 is tightened to make the inner cone plastic grinding body 4 fit into the outer cone section 102, then the inner hexagon screw is unscrewed 6 and unload the accessory adjustment top cap 5, which has just formed a kind of adjustable plastic grinding body high precision deep hole mirror grinding mandrel.

[0020] Before grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com