Aluminum alloy pulse ultrasound and electric arc composite welding device and method

An ultrasonic arc and composite welding technology, applied in the field of aluminum alloy welding, can solve problems such as affecting product quality and performance, weld metal cracks, loose material, etc., to improve arc instability, refine weld structure, and improve energy. The effect of distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

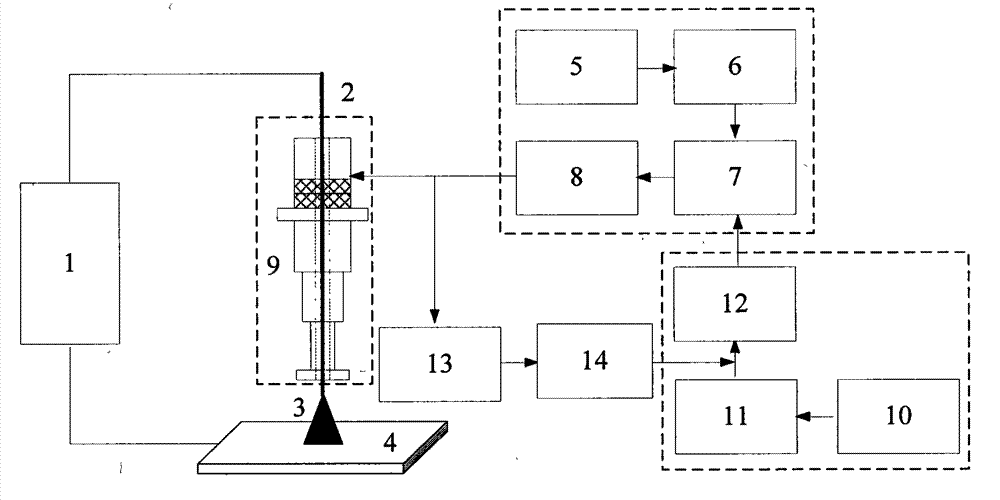

[0021] combine figure 1 , an aluminum alloy pulsed ultrasonic arc hybrid welding device, including a welding power source 1, an electrode 2, a transducer 9, and an ultrasonic generating system, the welding power source 1 is connected to the electrode 2, the electrode passes through the center of the transducer, and the ultrasonic generating system and The transducer 9 is connected, the welding power supply 1, the electrode 2 and the workpiece 4 to be welded form a complete arc 3 arc striking circuit system. According to different welding methods, the electrode 2 is a non-melting electrode tungsten electrode or a melting electrode welding wire. This device also includes a current Voltage detection circuit 13, DSP processor 14, single-chip microcomputer 10, triode switch circuit 11 and drive circuit 12; Current and voltage detection circuit 13 is connected with the output end of matching circuit 8 of ultrasonic generating system, current and voltage detection circuit 13 and DSP p...

Embodiment 2

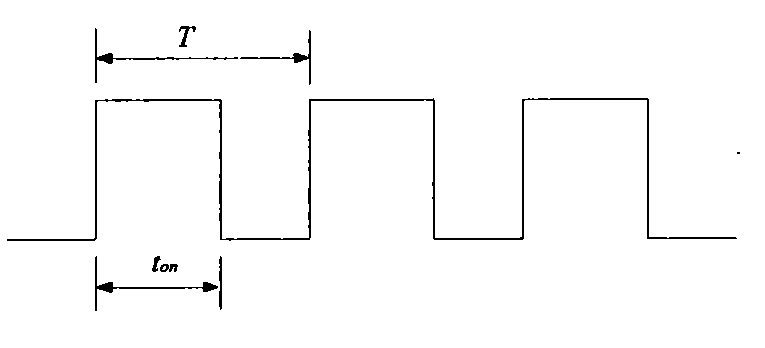

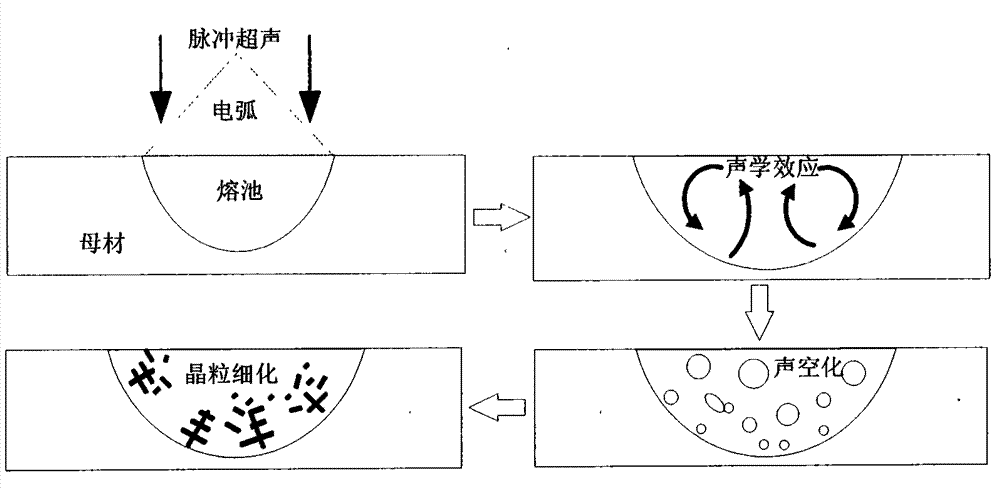

[0027] combine image 3 , an aluminum alloy pulsed ultrasonic arc hybrid welding method. It includes the following steps: ① Check the welding equipment before welding, clean the debris at the welding position of the workpiece to be welded, place the transducer above the workpiece to be welded, and fix the workpiece to be welded at the same time. The diameter of the lower surface of the transducer is 35mm. Non-melting electrode aluminum alloy plate welding is more suitable for thin plate welding with a thickness of less than 3mm. The distance between the upper surface of the workpiece to be welded and the lower end surface of the transducer is 12-28mm, while the melting electrode welding aluminum alloy plate is suitable for thick plate welding. The distance between the lower end faces of the device is required to be 5-15mm. ② During welding, first start the welding power supply 1 to start the arc, and then start the single-chip microcomputer 10 to control the opening and clos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com