Novel calcium enhancer based on poorly-soluble calcium and food-borne protein complexes as well as preparation method and characterization method thereof

An insoluble, complex technology, applied in food preparation, food science, color/spectral property measurement, etc., can solve the problems of easy precipitation, poor solubility, poor solubility, etc., and achieve simple and safe process, not easy to migrate, not easy to precipitate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Dispersion: Prepare whey protein isolate (WPI) into a 10mg / mL solution, accurately weigh 20mg of food-grade tricalcium phosphate (TCP) and disperse in 0.5mL ultrapure water to form a suspension;

[0033] (2) Mixing: at room temperature, add 0.5mL of 10mg / mL whey protein isolate solution into 0.5mL tricalcium phosphate suspension (when no pH adjustment is performed, the pH of the mixed solution is detected to be ~7.0), and mix the two evenly , cultivated on a rotary incubator for 4 hours;

[0034] (3) Separation: After the above reaction is completed, the mixed solution is centrifuged (4000r / min, 10min), the supernatant and the precipitate are separated, the precipitate is redispersed in water, and spray-dried to obtain tricalcium phosphate compounded with whey protein isolate;

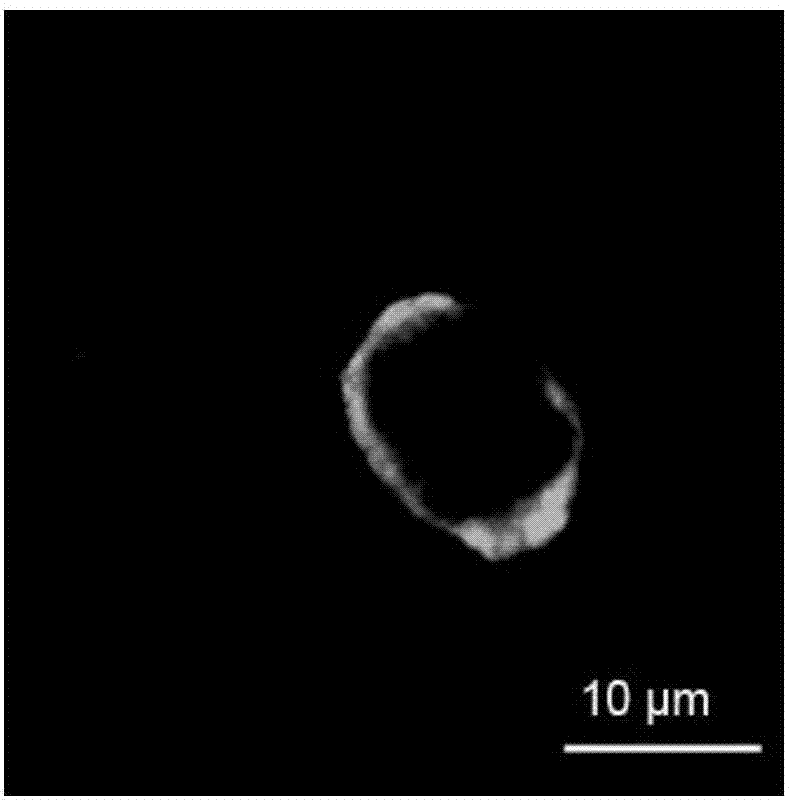

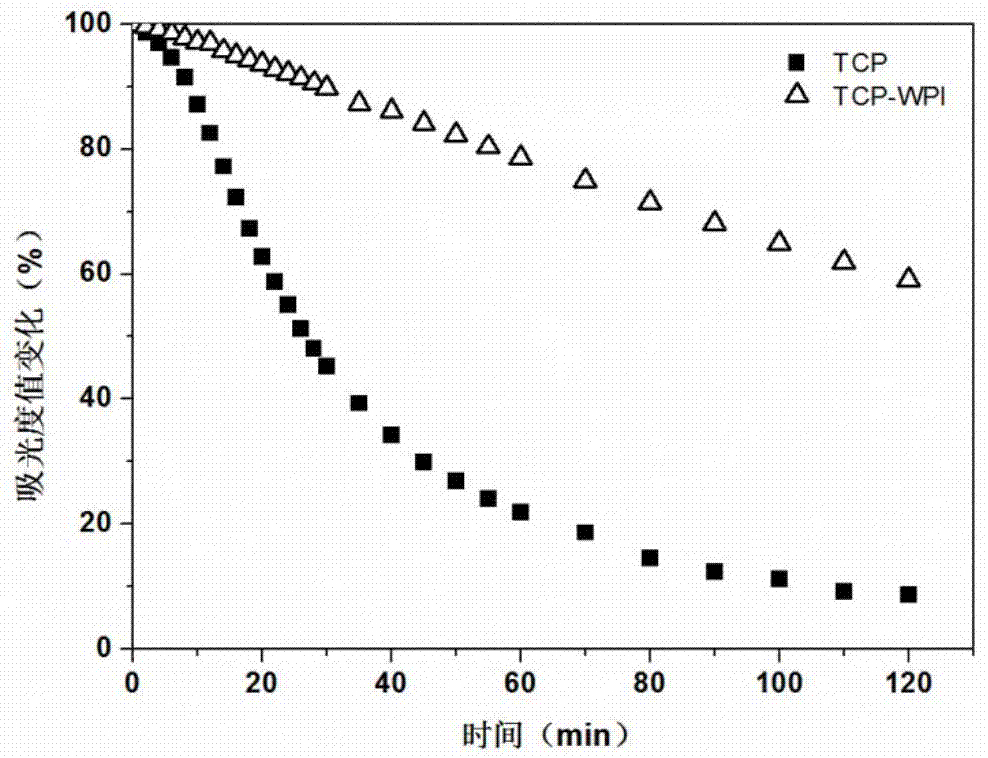

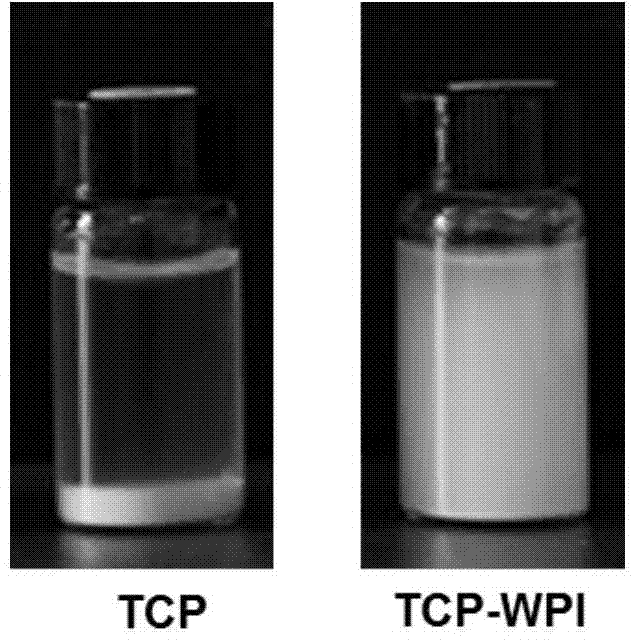

[0035] (4) Separation of staining and laser confocal imaging: after step (2), centrifuge the mixture (4000r / min, 10min), separate the supernatant and precipitate, rinse the precipitate and r...

Embodiment 2

[0039] (1) Dispersion: Prepare sodium caseinate (SC) into a 2 mg / mL solution, and accurately weigh 100 mg of food-grade calcium carbonate (CaCO 3 ) is dispersed in 2.5mL ultrapure water to form a suspension;

[0040] (2) Mixing: at room temperature, add 2.5mL of 10mg / mL sodium caseinate solution into 2.5mL of calcium carbonate suspension (when no pH adjustment is performed, the pH of the mixed solution is detected to be ~9.0), mix the two evenly, Spin culture on a rotary incubator for 2 h.

[0041] (3) Separation: After the above reaction is completed, the mixed solution is centrifuged (4000r / min, 10min), the supernatant and the precipitate are separated, the precipitate is redispersed in water, and spray-dried to obtain calcium carbonate compounded with sodium caseinate (CaCO 3 -SC).

[0042] (4) Separation of staining and laser confocal imaging: after step (2), centrifuge the mixture (4000r / min, 10min), separate the supernatant and precipitate, rinse the precipitate and re...

Embodiment 3

[0046] (1) Dispersion: Prepare milk protein concentrate (MPC) into a 10mg / mL solution, and accurately weigh 100mg of food-grade calcium carbonate (CaCO 3 ) and tricalcium phosphate (TCP) were dispersed in 2.5mL ultrapure water to form a suspension;

[0047] (2) Mixing: at room temperature, add 2.5mL of 10mg / mL MPC to 2.5mL of CaCO 3 and TCP suspension, mix well, and the control group (100mg CaCO 3 and 100mg TCP respectively dispersed in 5mL ultrapure water) together on a rotary incubator for 4 hours;

[0048] (3) Separation: After the above reaction is completed, the mixed solution is centrifuged (4000r / min, 10min), the supernatant and the precipitate are separated, the precipitate is redispersed in water, and spray-dried to obtain calcium carbonate (CaCO3) compounded with milk protein concentrate. 3 -MPC) and tricalcium phosphate (TCP-MPC).

[0049] (4) Separation of staining and laser confocal imaging: after step (2), centrifuge the mixture (4000r / min, 10min), separate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com