Negative image treatment-free lithograph plate

A processing-free, lithographic technology, applied in the field of negative-image processing-free lithographic printing plates and processing-free lithographic printing plates on printing presses, can solve problems such as insufficient print durability, and achieve improved print durability and strong adsorption. , the effect of improved wear resistance and chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

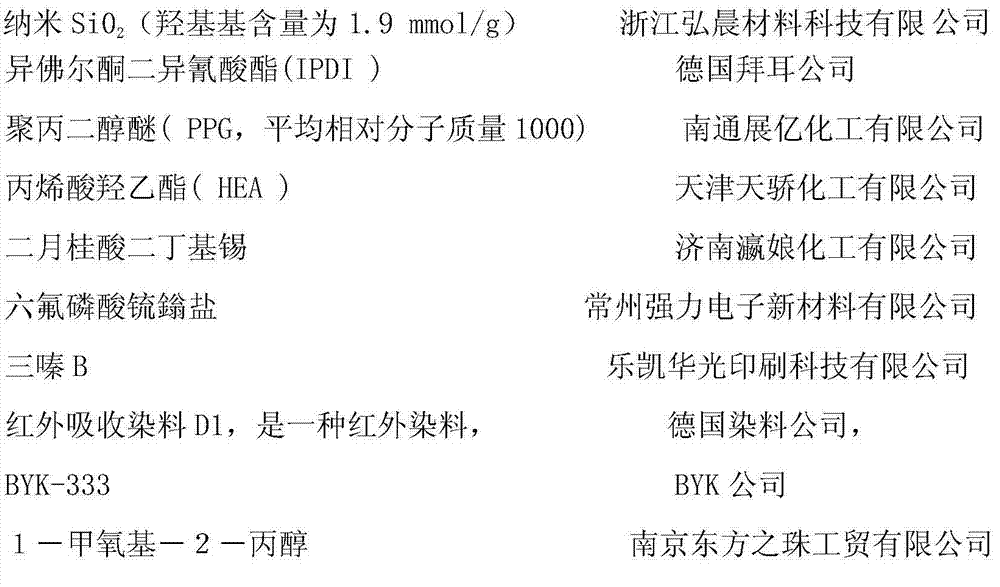

[0063] 100 grams of IPDI, 7.6 grams of nano-SiO with a diameter of 50nm 2 (hydroxyl value 1.9mmol / g) and 1g of dibutyltin dilaurate catalyst were added to a 500mL four-neck flask equipped with a thermometer, stirrer and nitrogen gas introduction device, and the 2 Stir and react at 60°C for 8 hours under protection, use the chemical titration method to determine that the -NCO content will no longer decrease, add 220 grams of PPG, wait for the temperature reaction to reduce the -NCO content to 45%, add 51.4 grams of HEA, and measure it by infrared spectroscopy 2235cm-NCO characteristic absorption peak disappears completely. Obtain about 380.0 g SiO 2 / Urethane Acrylic Prepolymer B1.

Synthetic example 2

[0065] 100 grams of IPDI, 19.0 grams of nano-SiO with a diameter of 10nm 2 Add 1g of dibutyltin dilaurate catalyst into a 500mL four-neck flask equipped with a thermometer, stirrer and nitrogen gas introduction device, under N 2 Stir and react at 60°C for 8 hours under protection, use chemical titration to determine that the -NCO content does not drop anymore, add 216.0 grams of PPG, wait for the temperature reaction to reduce the -NCO content to 45%, add 50.0 grams of HEA, and measure by infrared spectroscopy 2235cm-NCO characteristic absorption peak disappears completely. Obtain about 385.0 g of SiO 2 / Urethane Acrylic Prepolymer B2.

Synthetic example 3

[0067] 100 grams of IPDI, 1.9 grams of nano-SiO with a diameter of 100nm 2 (hydroxyl value 1.9mmol / g) and 1g of dibutyltin dilaurate catalyst were added to a 500mL four-neck flask equipped with a thermometer, stirrer and nitrogen gas introduction device, and the 2 Stir and react at 60°C for 8 hours under protection, use the chemical titration method to determine that the -NCO content will no longer decrease, add 224 grams of PPG, wait for the temperature reaction to reduce the -NCO content to 45%, add 52 grams of HEA, and use infrared spectroscopy to determine 2235cm-NCO characteristic absorption peak disappears completely. Obtain about 378.0 g SiO 2 / Urethane Acrylic Prepolymer B2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com