Recoverable artificial lawn and preparation method thereof

An artificial turf and artificial grass silk technology, applied in the field of artificial turf, can solve the problems of poor water permeability of the lawn system, insufficient grass silk pulling force, difficult to popularize and apply, etc., achieve good drainage performance, avoid pollution, and save manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of contrast sample is as follows:

[0050] (1) Artificial turf tufting is made into a semi-finished product on a conventional base cloth, and the artificial turf used, the line spacing and needle pitch of the tufting etc. are consistent with the embodiments of the present invention;

[0051] (2) Coat the back of the semi-finished product with styrene-butadiene and PU latex according to the normal amount of glue. After drying and curing, the finished product is obtained, and drain holes are made according to the conventional requirements.

[0052] Performance testing:

[0053] The pull-out force of the grass is tested according to the ISO4919-1978 standard required by FIFA; the water permeability of the lawn is tested according to the EN12616-200 standard required by FIFA.

[0054] Embodiment is described as follows:

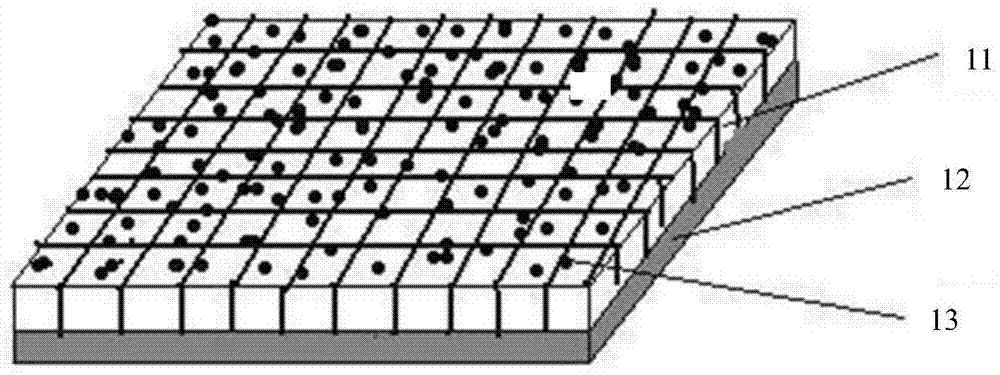

[0055] In embodiment 1-8, the selected specification of base cloth A is: 120g / m 2 Non-woven +70g / m 2 Mesh cloth (mesh size 2×2m...

Embodiment 1

[0059] According to 100g / m 2 Spread the PP hot-melt adhesive powder evenly on the base fabric A compounded by the grid cloth and the non-woven fabric, and pass through the heating device at a transmission speed of 6m / min. The heating temperature is controlled at 180-190°C. After the cloth and the non-woven fabric are bonded together, the base cloth A is obtained through cooling and rolling.

[0060] According to 60g / m 2 Spread PP hot-melt adhesive powder evenly on the base fabric B combined with grid cloth and non-woven fabric, and pass through the heating device at a transmission speed of 6m / min. The heating temperature is controlled at 180-190°C. After the cloth and the non-woven fabric are bonded together, the base cloth B is obtained through cooling and rolling.

[0061] According to the corresponding needle pitch and line spacing, the artificial turf is clustered on the base fabric A (the grid surface is below) to obtain a semi-finished lawn, and the base fabric B of th...

Embodiment 2

[0063] According to 100g / m 2 Spread the PP hot-melt adhesive powder evenly on the base fabric A compounded by the non-woven fabric and the mesh cloth, pass through the heating device at a transmission speed of 5m / min, and control the heating temperature at 170-180°C. After the cloth and the non-woven fabric are bonded together, the base cloth A is obtained through cooling and rolling.

[0064] According to 60g / m 2 Spread the PP hot-melt adhesive powder evenly on the base fabric B composed of non-woven fabric and mesh cloth, pass through the heating device at a transmission speed of 5m / min, and control the heating temperature at 170-180°C. After the cloth and the non-woven fabric are bonded together, the base cloth B is obtained through cooling and rolling.

[0065] According to the corresponding needle pitch and line spacing, the artificial turf is clustered on the base fabric A (the grid surface is below) to obtain a semi-finished lawn, and the base fabric B of the same siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com