Radial forging strain-induced semi-solid integral die forging process for blades

A radial forging and strain-induced technology, applied in the field of blade manufacturing, can solve the problems of poor mechanical properties of products, large design margins, and easy shrinkage of castings, and achieves fine microstructure grains, good mechanical properties of products, metal Streamline complete effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the drawings.

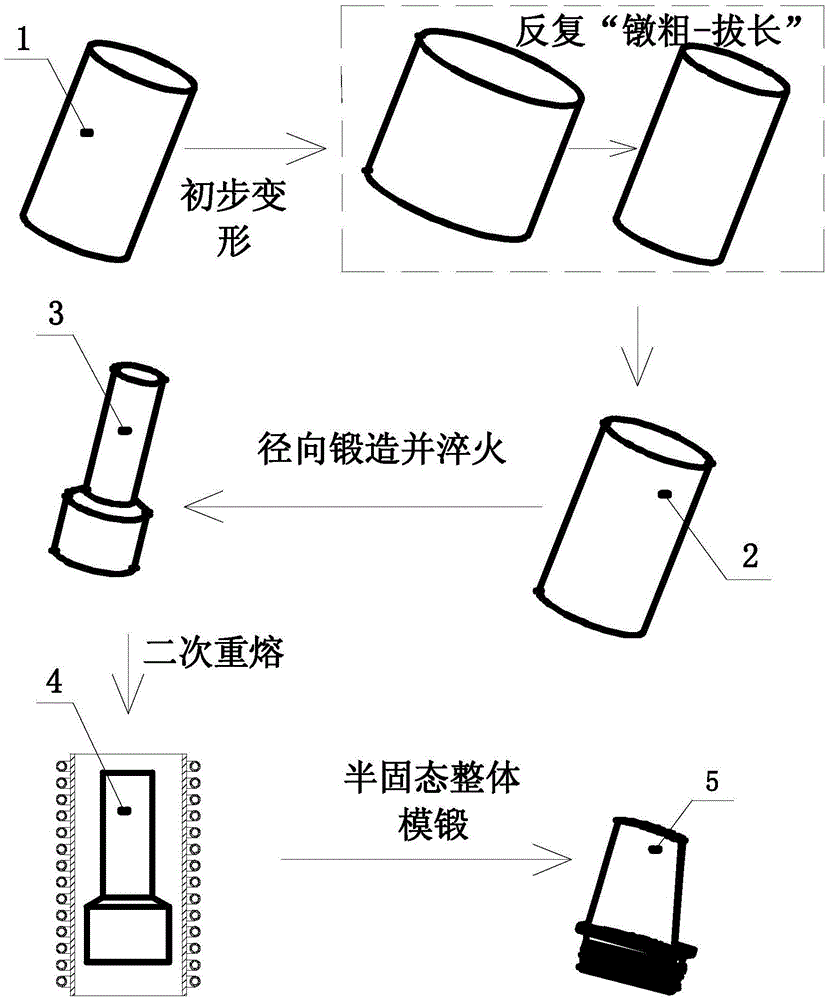

[0024] Reference figure 1 , The radial forging type strain-induced semi-solid integral die forging process of the blade includes the following steps:

[0025] 1) Preliminary deformation of the bar: first prepare a titanium alloy metal bar 1 for forming the blade. The selected metal bar 1 is made of titanium alloy Ti14, and its semi-solid temperature range is 990~1480℃; then the metal The bar 1 is heated to 880~940°C for preheating and the entire metal bar 1 is evenly heated through, and repeated upsetting and drawing are performed to obtain the deformed metal bar 2 with storage distortion energy;

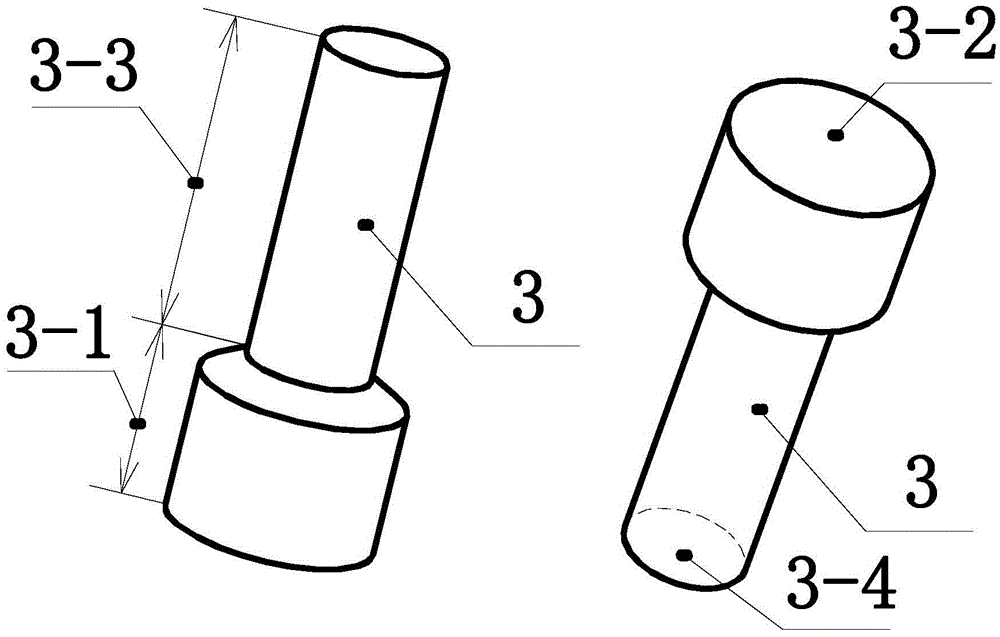

[0026] 2) Radial forging of bars: reference figure 2 and image 3 , Using waste heat to radially forge and quench the distorted metal bar 2 obtained in step 1) to obtain a stepped radial forging distorted blank 3, and radially forge the radial section of the large end of the distorted blank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com