Kieselguhr humidity regulating plate and preparation method thereof

A technology of diatom conditioning and plates, which is applied in the manufacture of tools, ceramic products, and other household appliances. It can solve the problems of affecting the investment return cycle of the production line, high equipment investment, and unfavorable promotion, so as to improve the quality of life of the crowd and reduce equipment investment. , change the effect of a single variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

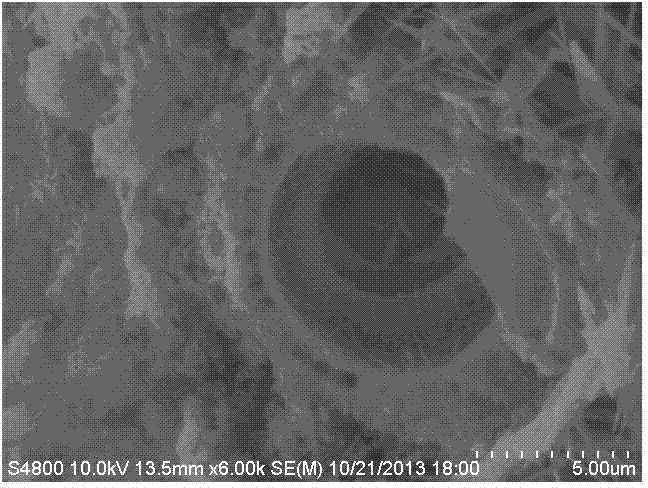

Image

Examples

Embodiment 1

[0033] Raw materials: diatomite is from a mine in Jilin, its diatom frustule content is 44%, SiO 2 Content 61%, specific surface area 86m 2 / g; the calcareous raw material adopts light gray slaked lime powder, the purity is 95%, and the fineness is 200 mesh; the cement adopts P.O 42.5 ordinary portland cement; the fluidizing agent adopts carboxylate polymer; 40% expanded perlite particles, fineness 200 mesh; fiber is paper fiber; water is tap water.

[0034]The method for preparing a diatom humidity-regulating board of the present invention: (a), mixing and dissolving, selecting solid raw materials according to the mass parts: 90 parts of diatomite; 30 parts of calcareous raw materials; 40 parts of cement; 7 parts of fiber; fluidization 3 parts of agent; 35 parts of expanded perlite; the ratio of water to the solid raw material is 1.5, diatomite, calcareous raw material, cement, fiber are added to the container of a mechanical mixer and mixed evenly, and the fluidizing agent ...

Embodiment 2

[0036] Raw materials: Calcareous raw materials are quicklime powder with a fineness of 200 meshes; fluidizers are made of sulfonate polymers; lightweight fillers are made of light ceramic sand particles that do not exceed 40% of the mass of diatomite with a fineness of 200 meshes.

[0037] The method for preparing a diatom humidity-regulating board of the present invention: (a), mixing and dissolving, selecting solid raw materials according to the mass parts: 100 parts of diatomite; 10 parts of calcareous raw materials; 20 parts of cement; 5 parts of fiber; fluidization 0.5 parts of agent; 30 parts of light filler; the ratio of water to the solid raw material is 1.2; (b), making slurry, adding the fluidizing agent solution to be used in three times into the running mixer container, each time The interval between adding the fluidizing agent solution is 10 minutes, and the corresponding slurry test cone with a volume of 111ml is used, and the horizontal fluidity of the slurry tes...

Embodiment 3

[0039] Raw materials: Calcareous raw materials are calcined dolomite powder, fineness 200 mesh; lightweight fillers are hollow vitrified microbeads not exceeding 40% of the mass of diatomite, fineness 200 mesh; fiber is pulp made of waste paper and water crushed .

[0040] The method for preparing a diatom humidity-regulating board of the present invention: (a), mixing and dissolving, selecting solid raw materials according to the mass parts: 80 parts of diatomite; 50 parts of calcareous raw materials; 60 parts of cement; 10 parts of fiber; fluidization 5.0 parts of agent; 30 parts of light filler; the ratio of water to the solid raw material is 2.0; (b), making slurry, adding the ready-to-use fluidizing agent solution into the running mixer container three times, each time The interval between adding the fluidizing agent solution is 5 minutes, and the corresponding slurry test cone with a volume of 111ml is used, and the horizontal fluidity of the slurry test cone is 150mm; (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com