Method for processing oily sludge through supercutical fluid

A supercritical fluid and oil sludge technology, which is applied in sludge treatment, special treatment targets, mining wastewater treatment, etc., can solve the problems of waste of crude oil resources, complicated treatment process, high treatment cost, etc. Simple process and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

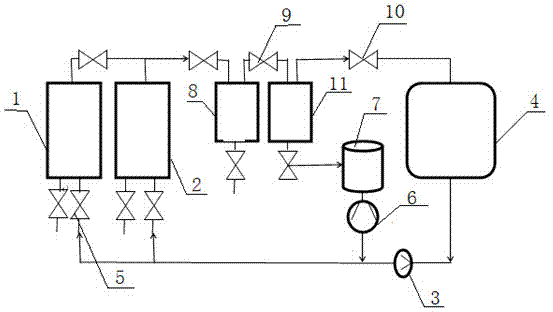

[0026] First, set the extraction temperature, extraction pressure, and separation temperature and separation pressure to 35°C, 15MPa, 40°C, 5MPa, put 1000 grams of pretreated oily sludge into the extractor 1, and the other extractor 2 to be used Standby, when the extraction temperature is stable at 35°C, pump carbon dioxide from the carbon dioxide storage tank 4 into the extractor 1 through the carbon dioxide high-pressure pump 3, adjust the pressure of the extractor to 15 MPa through the valve 5, and at the same time, through the carrier pump 6 The carrier acetone is injected into the extractor according to the weight ratio of 15% of the amount of carbon dioxide from the carrier tank 7, and then the carbon dioxide and the carrier agent dissolved in the fuel oil are allowed to enter the primary separator 8, and the pressure of the separator is adjusted through the valve 9 8MPa, let the fuel oil be separated out in the primary separator 8, adjust the pressure of the secondary se...

Embodiment 2

[0028] First, set the extraction temperature, extraction pressure and separation temperature and separation pressure to 45°C, 30MPa, 40°C, 5MPa, put 1000 grams of pretreated oily sludge into the extractor 1, and the other extractor 2 to be used Standby, when the extraction temperature is stable at 45°C, pump carbon dioxide from the carbon dioxide storage tank 4 into the extractor 1 through the carbon dioxide high-pressure pump 3, adjust the pressure of the extractor to 30 MPa through the valve 5, and at the same time, through the carrier pump 6 The carrier agent ethyl acetate is injected into the extractor according to the weight ratio of 15% of the amount of carbon dioxide from the carrier agent tank 7, and then the carbon dioxide and the carrier agent dissolved in the fuel oil are allowed to enter the primary separator 8, and the separation is regulated by the valve 9 The device pressure is 8MPa, allowing the fuel oil to separate out in the primary separator 8, regulating the...

Embodiment 3

[0030] First, set the extraction temperature, extraction pressure and separation temperature and separation pressure to 55°C, 45MPa, 40°C, 5MPa, put 1000 grams of pretreated oily sludge into the extractor 1, and the other extractor 2 to be used Standby, when the extraction temperature is stable at 550°C, pump carbon dioxide from the carbon dioxide storage tank 4 into the extractor 1 through the carbon dioxide high-pressure pump 3, adjust the pressure of the extractor to 45 MPa through the valve 5, and at the same time, through the carrier pump 6 The carrier agent acetocyanide is injected into the extractor 1 according to the weight ratio of 20% of the amount of carbon dioxide from the carrier tank 7, and then the carbon dioxide and the carrier agent dissolved in the fuel oil are allowed to enter the primary separator 8, and the separation is regulated by the valve 9 The device pressure is 8MPa, allowing the fuel oil to separate out in the primary separator 8, regulating the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com