Synthesis method of HZSM-5 molecular sieve

A synthesis method and molecular sieve technology, applied in the chemical industry, can solve the problems of complicated preparation process, long time consumption, harm and the like, and achieve the effects of simplifying the preparation process, high yield and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

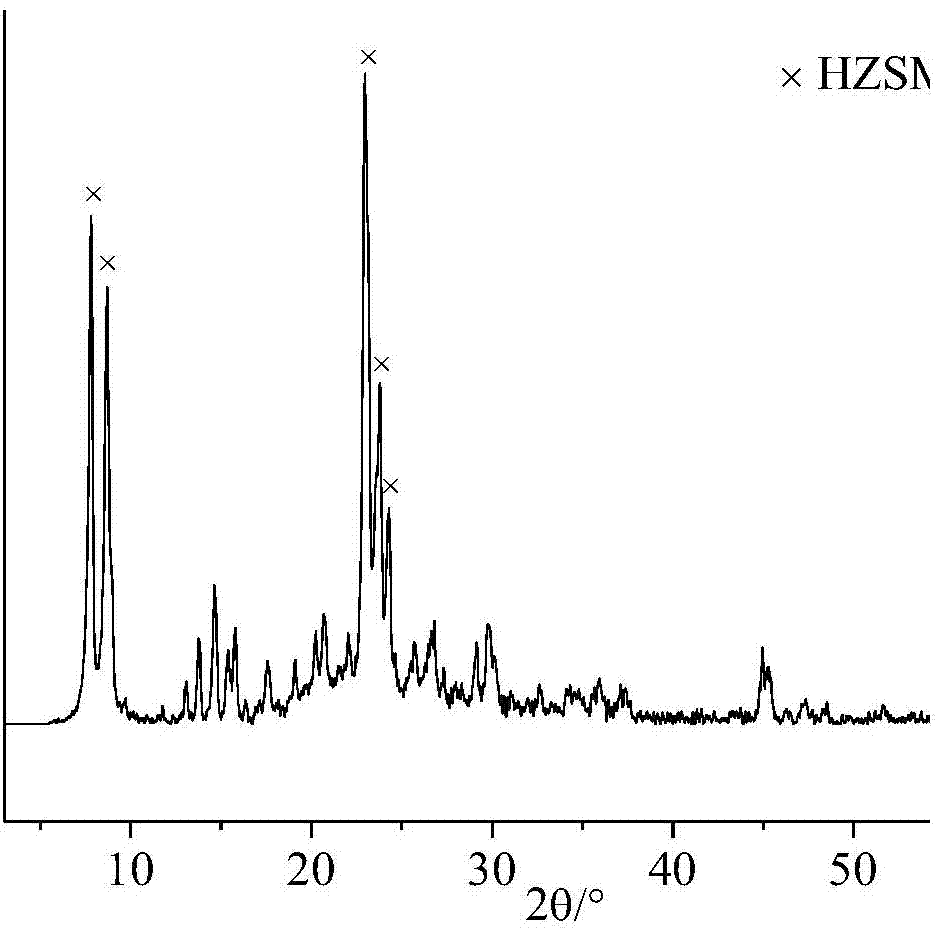

[0031] According to the synthesis ratio SiO 2 :Al 2 O 3 :TPA + :NH 3 :C 2 H 5 OH:H 2 O=100:1:40:250:300:2200, mix 13.313g TPABr, 5g deionized water, 43.75g ammonia water, stir evenly, add 17.25g C 2 H 5 OH and 0.9378g aluminum nitrate were stirred for 2h, 18.75g silica sol was added dropwise, and stirring was continued for 2h, the obtained gel was dried at 80°C for 12h, and ground in a mortar for 10min to obtain a dry powder. Weigh 3g of dry gel powder, put it into a crucible, place the crucible in a crystallization reaction kettle with 15g of water at the bottom, crystallize at 180℃ for 72h, cool to room temperature, filter and wash until neutral, dry at 120℃ for 12h, 550 It is calcined at ℃ for 6h to obtain HZSM-5 molecular sieve powder. The synthesis yield is based on the ratio of the quality of the product obtained after roasting to the theoretical output quality, and the yield is 90%. The XRD spectrum of the obtained product sample is as follows figure 1 Shown.

Embodiment 2

[0033] According to the synthesis ratio SiO 2 :Al 2 O 3 :TPA + :NH 3 :C 2 H 5 OH:H 2 O=100:1:30:250:250:2200, mix 9.9848g TPABr, 5g deionized water, 43.75g ammonia water, stir evenly, add 14.375g C 2 H 5 OH and 0.9378g aluminum nitrate were stirred for 2h, 18.75g silica sol was added dropwise, and stirring was continued for 2h, the obtained gel was dried at 90°C for 12h, and ground in a mortar for 10min to obtain a dry powder. Weigh 3g of dry gel powder, put it into a crucible, place the crucible in a crystallization reaction kettle with 15g of water at the bottom, crystallize at 180℃ for 72h, cool to room temperature, filter and wash until neutral, dry at 120℃ for 12h, 550 It was calcined at ℃ for 6 hours to obtain HZSM-5 molecular sieve powder with a yield of 88%.

Embodiment 3

[0035] According to the synthesis ratio SiO 2 :Al 2 O 3 :TPA + :NH 3 :C 2 H 5 OH:H 2 O=100:1:50:250:300:2200, mix 16.6406g TPABr, 5g deionized water, 43.75g ammonia water, stir evenly, add 17.25g C 2 H 5 OH and 0.9378g aluminum nitrate were stirred for 2h, 18.75g silica sol was added dropwise, and stirring was continued for 3h, the obtained gel was dried at 100°C for 12h, and ground in a mortar for 10min to obtain a dry powder. Weigh 3g of dry gel powder, put it into a crucible, place the crucible in a crystallization reaction kettle with 15g of water at the bottom, crystallize at 180℃ for 72h, cool to room temperature, filter and wash until neutral, dry at 120℃ for 12h, 550 It was calcined at ℃ for 6 hours to obtain HZSM-5 molecular sieve powder with a yield of 88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com