Method for synthesizing Cu-SSZ-13 in one step under sodium-free system

A cu-ssz-13 system technology, applied in the direction of chemical instruments and methods, molecular sieve catalysts, physical/chemical process catalysts, etc., can solve problems such as complicated and complicated processes, and avoid ion exchange and calcination processes , process simplification, beneficial to load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

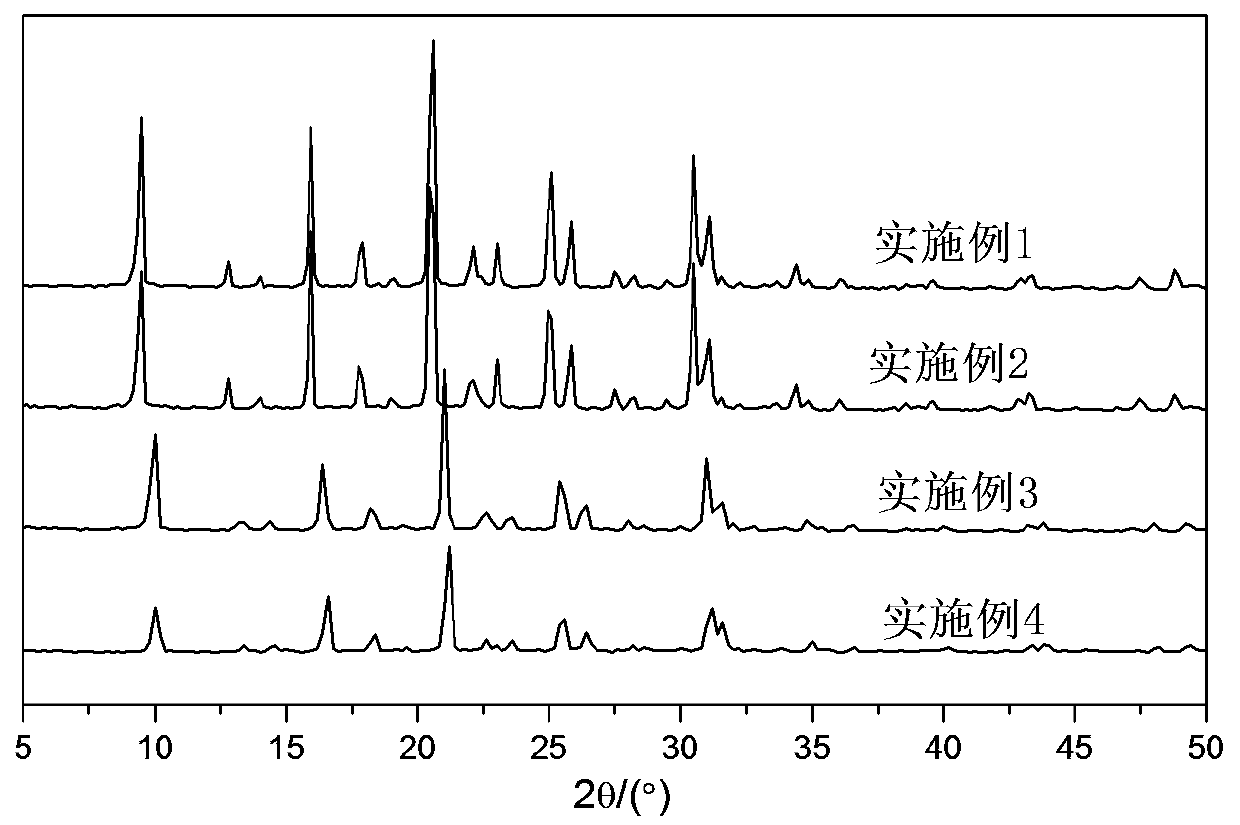

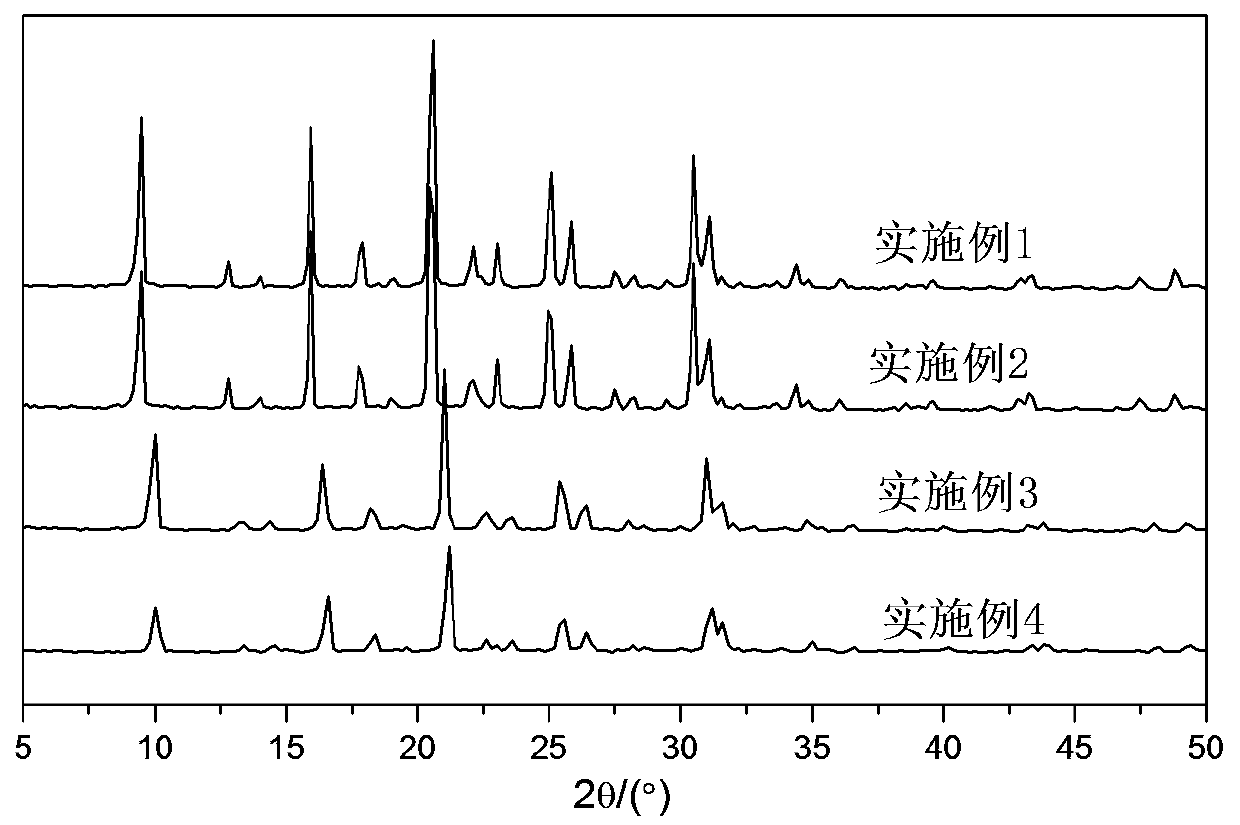

Embodiment 1

[0028] Configuration of copper ammonium complex: first add copper sulfate pentahydrate to 10 times the amount of deionized water, stir until it is completely dissolved, and obtain an aqueous solution of copper sulfate, and then use a molar ratio of 1.0Cu 2+ : 4.0NH 3 ·H 2 O Add ammonia water (25wt%) gradually into the copper sulfate aqueous solution, stir evenly to obtain the copper ammonium complex.

[0029] Preparation of Cu-SSZ-13 molecular sieve: according to the synthetic molar ratio of 1.0SiO 2 : 0.05Al 2 o 3 : 0.05Cu-NH 3 : 0.004C 2 h 5 OH: 0.2R: 30H 2 O, first measure aluminum isopropoxide (Al 2 o 324.0wt%) into the metered deionized water, stirred rapidly for 10min; added into the metered N,N,N-trimethyladamantyl ammonium hydroxide (TMADaOH 25wt%), stirred until completely dissolved, added the metered copper ammonium complex Stir rapidly for 10 minutes; finally add metered ammonium silica sol (SiO 2 25wt%) was fully stirred to get the initial gel. Seal it...

Embodiment 2

[0031] The configuration of copper ammonia complex: first add copper nitrate trihydrate to 10 times the amount of deionized water, stir until it is completely dissolved, and obtain an aqueous solution of copper nitrate, and then use a molar ratio of 1.0 Cu 2+ : 5.0NH 3 ·H 2 O gradually add ammonia water (25wt%) into the copper nitrate aqueous solution, stir evenly to obtain the copper ammonium complex.

[0032] Preparation of Cu-SSZ-13 molecular sieve: according to the synthetic molar ratio of 1.0SiO 2 : 0.1Al 2 o 3 : 0.02Cu-NH 3 : 0.001C 2 h 5 OH: 0.1R: 50H 2 O, first add metered triisobutylaluminum (1.0mol / L) into metered deionized water, stir rapidly for 10min; add metered N,N,N-trimethyladamantyl ammonium hydroxide (TMADaOH 25wt%), Stir until it is completely dissolved, add and measure the above-mentioned copper ammonia complex, and stir rapidly for 10 minutes; finally add and measure ethyl orthosilicate (SiO 2 28.80wt%) was fully stirred to get the initial gel. ...

Embodiment 3

[0034] Configuration of copper ammonium complex: first add copper acetate monohydrate to 10 times the amount of deionized water, stir until it is completely dissolved, and obtain an aqueous solution of copper acetate, and then use a molar ratio of 1.0Cu 2+ : 6.0NH 3 ·H 2 O gradually add ammonia water (25wt%) into the copper acetate aqueous solution, and stir evenly to obtain the copper ammonium complex.

[0035] Preparation of Cu-SSZ-13 molecular sieve: according to the synthetic molar ratio of 1.0SiO 2 : 0.07Al 2 o 3 : 0.12Cu-NH 3 : 0.01C 2 h 5 OH: 0.4R: 40H 2 O, first add metered triethylaluminum (1.0mol / L) into metered deionized water, stir rapidly for 10min; add metered N,N,N-trimethyladamantyl ammonium hydroxide (TMADaOH 25wt%), stir Until it is completely dissolved, add and measure the above-mentioned copper ammonium complex, and stir rapidly for 10 minutes; finally add and measure ethyl orthosilicate (SiO 2 28.80wt%) and ammonium silica sol (SiO 2 25wt%) mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com