High-strength degradable cartilage tissue engineering scaffold and preparation method thereof

A cartilage tissue, high-strength technology, applied in the field of high-strength degradable cartilage tissue engineering scaffold and its preparation, chitosan/gelatin composite porous scaffold for cartilage repair and reconstruction and its preparation field, can solve the problem of unknown degradation performance, mechanical properties and poor performance. Biocompatibility is not up to the problem, to achieve the effect of controllable degradation rate, high strength, high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

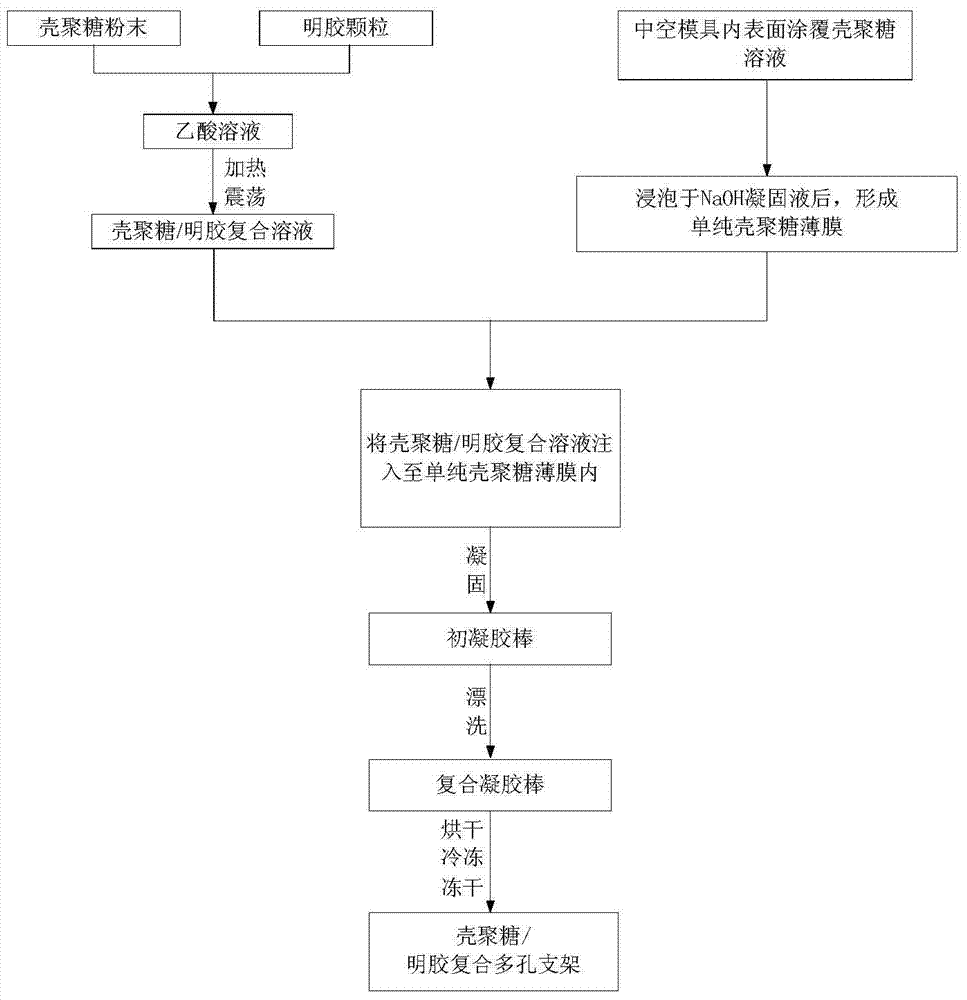

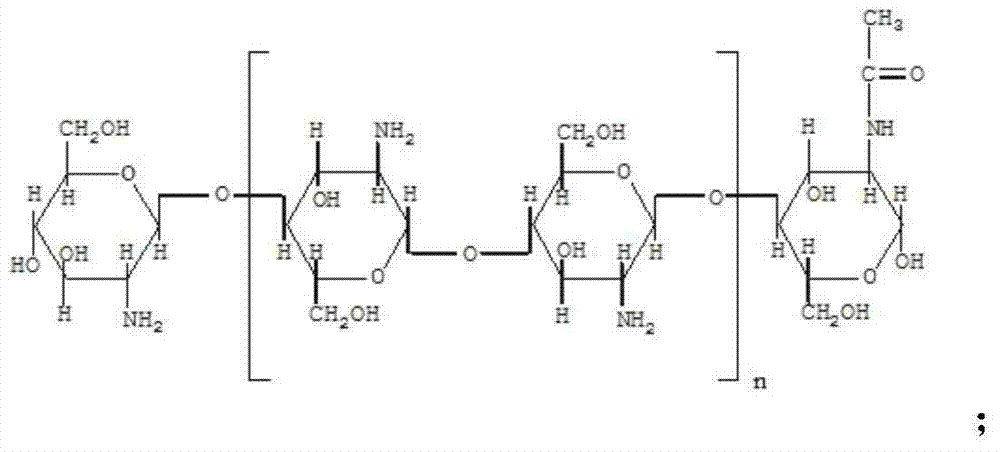

[0030] (1) Dissolve 2ml acetic acid in 100ml deionized water to form a 2% acetic acid solution by volume percentage, then dissolve 4g chitosan and 4g gelatin in 2% acetic acid solution by volume to form the final mass volume of chitosan ratio of 4% and gelatin mass volume ratio of 4% mixed solution, mix evenly and seal, place in 50°C water bath and stir at 100 rpm for 24h until a light yellow homogeneous and stable solution is formed, stand for 12h for defoaming , to obtain chitosan / gelatin composite solution;

[0031] (2) Take 5 mL of chitosan aqueous solution with a mass percentage content of 5% and inject it into the mold, soak in a sodium hydroxide solution with a mass percentage content of 5% for 10 minutes to form a layer of inner film with a thickness of 0.5 mm, and then remove the mold;

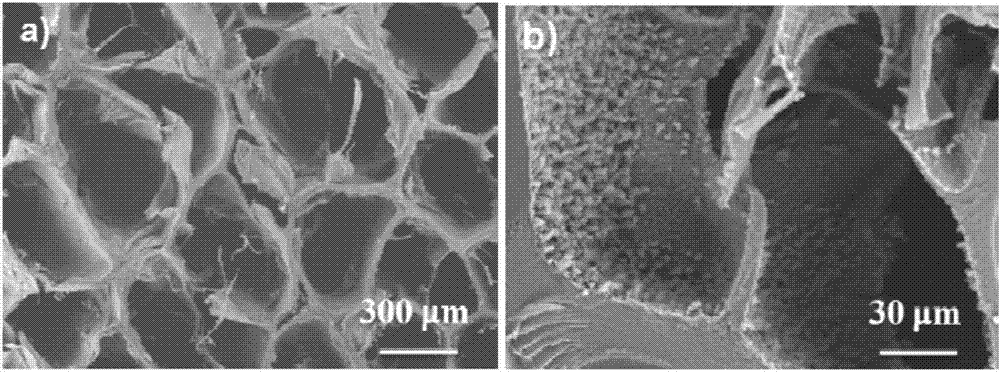

[0032] (3) Fill the film with chitosan / gelatin mixed solution, put it into the same coagulation solution for 12 hours, then remove the prepared gel stick and put it into distilled wa...

Embodiment 2

[0040] Same as Example 1, but the addition of gelatin in step (1) becomes 2g, and others remain unchanged.

[0041] The chitosan / gelatin porous composite scaffold obtained in this embodiment is a composite scaffold in which the weight ratio of chitosan and gelatin is 2:1, wherein the mass percentage concentration of chitosan is 4%, and the mass percentage concentration of gelatin is 2%. .

Embodiment 3

[0043] Same as embodiment 1, but the add-on of gelatin becomes 8g in the step (1), other changeless.

[0044] The chitosan / gelatin porous composite scaffold obtained in this embodiment is a composite scaffold in which the weight ratio of chitosan and gelatin is 1:2, wherein the mass percentage concentration of chitosan is 4%, and the mass percentage concentration of gelatin is 8%. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com