Prednisone oral pulsatile tablet and preparation method thereof

The technology of pulse and prednisone is applied in the field of oral prednisone pulse preparation and its preparation, which can solve the problems of short action time and large fluctuation of blood drug concentration, and achieve the effects of reducing the therapeutic effect and solving the low curative effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

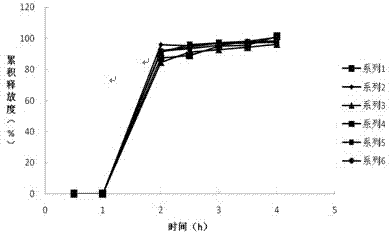

Embodiment 1

[0042] Chip core (10000 pieces):

[0043]

[0044] The raw and auxiliary materials used are passed through 80 mesh sieves, and the prescription amount of prednisone, PVPP, cross-linked CMC-Na, sorbitol, pregelatinized starch and MCC are mixed evenly, and the prescription amount of SiO2 is added according to the method of equal addition. Mix in a multi-sport mixer for 30 minutes, then add the prescribed amount of magnesium stearate and mix for 10 minutes to obtain the mixed material, punch the uniformly mixed material with a shallow arc of 5.0 mm, and press with a single-punch tablet machine to obtain the required tablet core. The tablet core weighs about 125mg and has a hardness of 2.8kg±0.5kg.

[0045] Dissolve HPMC in 60% ethanol to make a coating solution, and prepare a 5% HPMC alcohol solution to obtain a swelling layer coating solution; place the tablet core in the coating pan, and adjust the angle of the tumbling coating pan to 30° °, the speed is 25~35 / min, ...

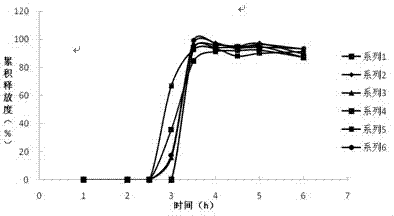

Embodiment 2

[0049] Chip core (10000 pieces):

[0050]

[0051] Pass the raw and auxiliary materials used through 80 mesh sieve, and mix the prescribed amount of prednisone, L-HPC, cross-linked CMC-Na, mannitol, lactose and MCC according to the method of equal addition, and then add the prescribed amount of SiO 2 , placed in a multi-sport mixer and mixed for 30 minutes, then added the prescribed amount of talcum powder and mixed for 10 minutes to obtain the mixed material, punched the uniformly mixed material with a shallow arc of 5.0 mm, and pressed it with a single-punch tablet machine to obtain the required tablet core. The tablet core weighs about 125mg and has a hardness of 2.1kg±0.5kg.

[0052] Dissolve HPMC in 60% ethanol to make a coating solution, and prepare a 5% HPMC alcohol solution to obtain a swelling layer coating solution; place the tablet core in the coating pan, and adjust the angle of the tumbling coating pan to 30° °, the speed is 25~35 / min, add the coating solution...

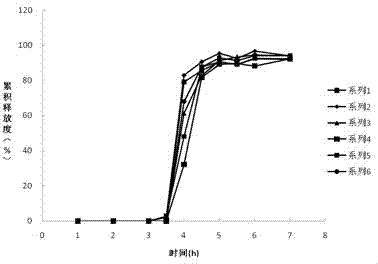

Embodiment 3

[0055] Chip core (10000 pieces):

[0056]

[0057]

[0058] Pass the used raw and auxiliary materials through 80 mesh sieves, and mix the prescribed amount of prednisone, PVPP, cross-linked CMC-Na, mannitol, lactose and MCC according to the method of equal addition, and then add the prescribed amount of SiO 2 , placed in a multi-sport mixer and mixed for 30 minutes, then added the prescribed amount of magnesium stearate and mixed for 10 minutes to obtain the mixed material, punched the uniformly mixed material with a shallow arc of 5.0mm, and pressed it with a single-punch tablet machine to obtain the desired tablet core. The tablet core weighs about 125mg and has a hardness of 2.5kg±0.5kg.

[0059] Dissolve HPMC in 60% ethanol to make a coating solution, and prepare a 5% HPMC alcohol solution to obtain a swelling layer coating solution; place the tablet core in the coating pan, and adjust the angle of the tumbling coating pan to 30° °, the speed is 25~35 / min, add the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com