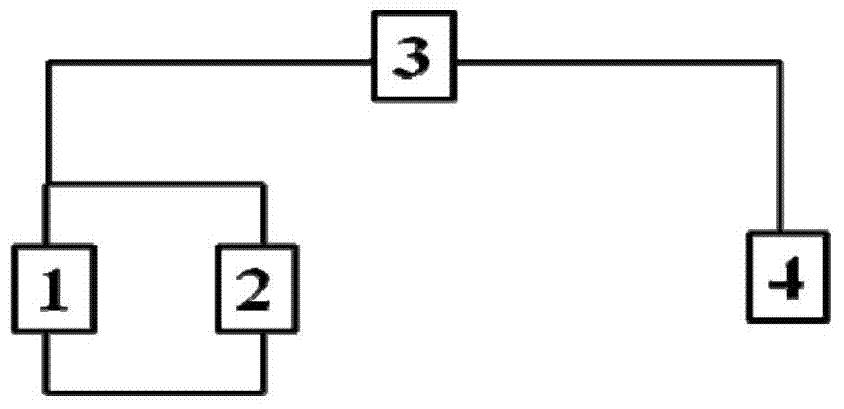

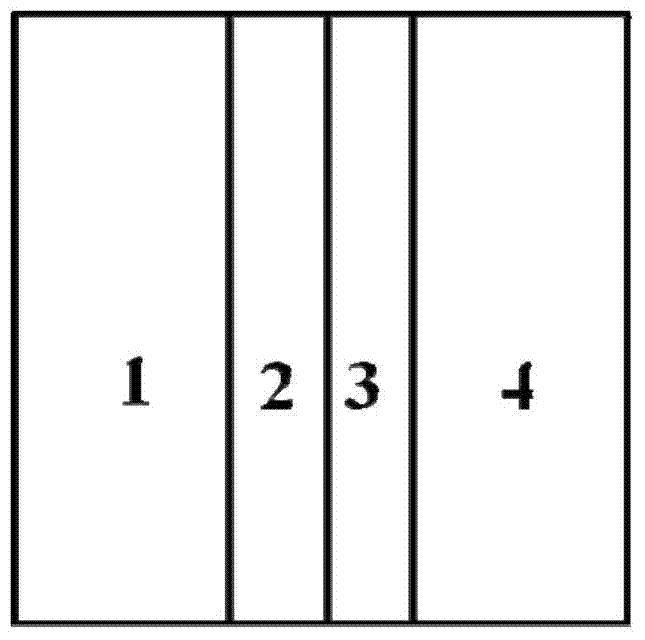

Lithium-sulfur battery structure

A sulfur battery and lithium negative electrode technology, applied in the field of lithium-sulfur battery structure, can solve the problems of high implementation cost, unfavorable commercial promotion and application of batteries, complicated process, etc., and achieve the effect of protecting the negative electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Blend 100mg KB600 carbon powder with polytetrafluoroethylene emulsion (PTFE, 5% mass fraction) in ethanol to obtain electrode slurry, wherein the mass ratio of carbon powder to polytetrafluoroethylene is 4:1, solid matter The ratio of the solvent to the solvent is 20 mg solid / ml solvent; the flake carbon layer is prepared by rolling, and dried at 60 degrees Celsius. The surface density of the carbon material in the carbon layer is 0.5 mg / cm 2 .

[0041] Mix sulfur and Super P carbon powder in a ball mill tank with a mass ratio of 3:1, and then keep it in an argon-protected tube furnace at 155 degrees Celsius for 2 hours to liquefy the elemental sulfur and enter the pores constructed by the carbon powder , the carbon-sulfur composite electrode material was obtained. Further, using it as the positive electrode material and PTFE as the binder, the mass ratio of the two is 9:1, and the same process as above is used to prepare the positive electrode for lithium-sulfur batte...

Embodiment 2

[0044] Blend 100mg of SuperP carbon powder with polytetrafluoroethylene emulsion (PTFE, 5% mass fraction) in ethanol to obtain electrode slurry, wherein the mass ratio of carbon powder to polytetrafluoroethylene is 4:1, solid matter The ratio of the solvent to the solvent is 20 mg solid / ml solvent; the flake carbon layer is prepared by rolling, and dried at 60 degrees Celsius. The surface density of the carbon material in the carbon layer is 0.5 mg / cm 2 .

[0045] Lithium sheet is used as the negative electrode, porous polypropylene diaphragm, 1M LiTFSi / TEGDME electrolyte, and the above carbon layer are used to assemble the lithium-air battery, in a pure oxygen atmosphere of 1.2 atmospheres, using 50mA / g (based on the quality of the carbon material) Discharge at a current density of 1 V, and the cut-off voltage is 1V. The discharged positive electrode is cleaned with ethylene glycol dimethyl ether to remove the electrolyte therein, and a conductive porous functional layer cont...

Embodiment 3

[0049] Blend 100mg of SuperP carbon powder with polytetrafluoroethylene emulsion (PTFE, 5% mass fraction) in ethanol to obtain electrode slurry, wherein the mass ratio of carbon powder to polytetrafluoroethylene is 4:1, solid matter The ratio of the solvent to the solvent is 20 mg solid / ml solvent; the flake carbon layer is prepared by rolling, and dried at 60 degrees Celsius. The surface density of the carbon material in the carbon layer is 0.5 mg / cm 2 .

[0050] The above electrode was placed in an aniline aqueous solution with a concentration of 1M hydrochloric acid and 1M ammonium sulfate, wherein the mass fraction of aniline was 10%, and stirred for 2 hours to obtain a polyaniline-modified functional layer. Stir and wash in deionized water to remove impurity ions, dry in a vacuum oven at 60 degrees Celsius, and use it as a conductive porous functional layer.

[0051] The carbon-sulfur composite positive electrode was prepared by the same process as in Example 1.

[0052...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com