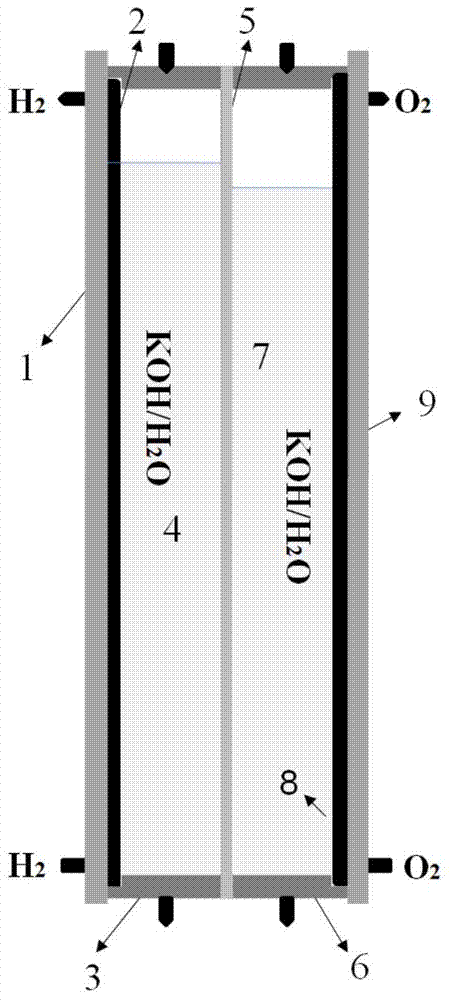

Electrochemical reactor for regeneration of chemical oxygen-iodine laser materials and regeneration method

An oxygen-iodine chemistry and laser technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of high cost, difficult to effectively guarantee the supply of raw materials, inconvenient transportation and storage, etc., to achieve a short production process, low intermediate loss, support The effect of low assurance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

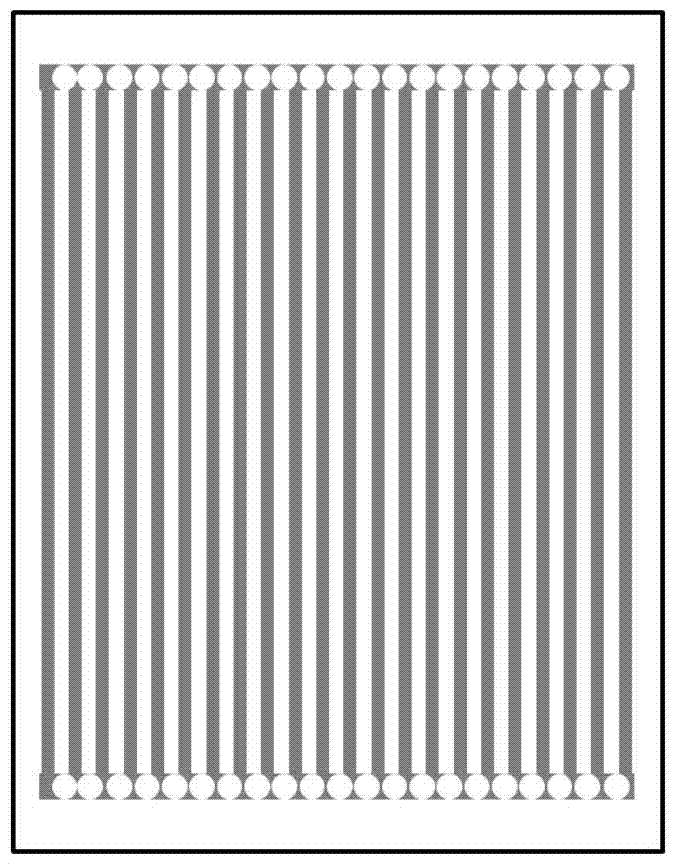

Embodiment 1

[0016] Anode using RuO 2 / C is used as a catalyst, and the cathode uses graphite powder as a catalyst. The process of preparing the cathode and anode electrodes is as follows: immerse the carbon paper in 10wt% PTFE emulsion for 1 to 2 minutes, take it out and dry it to remove the moisture therein. The amount of PTFE can be obtained by weighing the weight before and after impregnating PTFE, and the above process is repeated many times until the amount of PTFE impregnated into carbon paper meets the set requirements. Then put the above-mentioned hydrophobically treated carbon paper into a muffle furnace at 245° C. for half an hour to remove the surfactant in the PTFE emulsion. It was then treated at 345°C for another half an hour to melt the PTFE and form a hydrophobic network on the carbon paper fibers. PTFE content is 10wt.%. A microporous layer also needs to be prepared on the support layer to facilitate the loading of the catalyst. Weigh a certain amount of carbon powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com