Surface modification method of magnesium alloy

A surface modification and magnesium alloy technology, which is applied in metal material coating process, bulk chemical production, coating, etc., can solve the problems of magnesium alloy corrosion, achieve low preparation cost, improve corrosion resistance and cell response The effect of sex and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

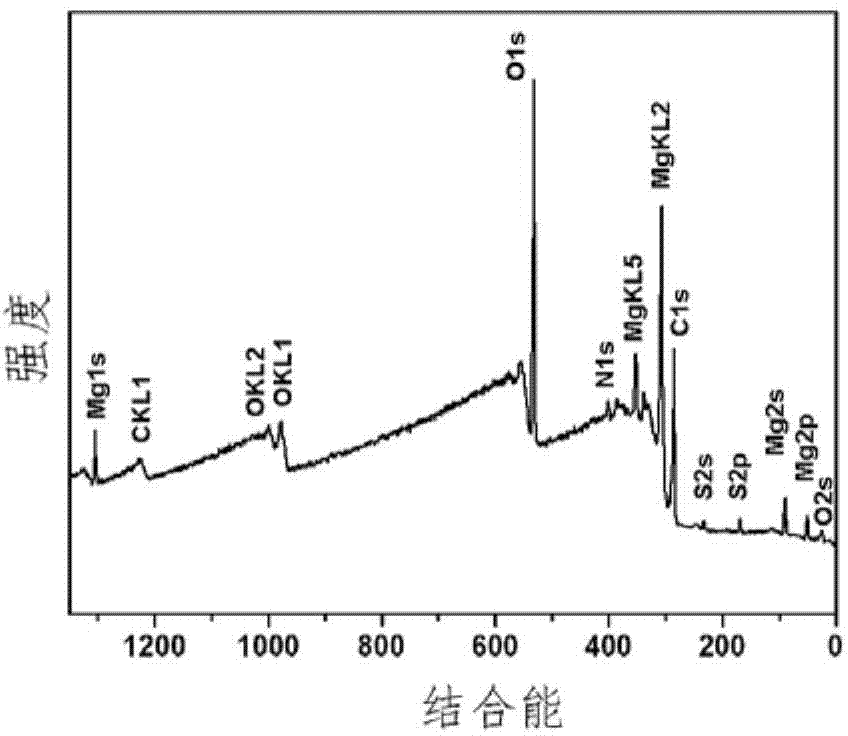

[0025] A method for modifying the surface of a magnesium alloy, the specific steps are as follows:

[0026] (1) Substrate pretreatment

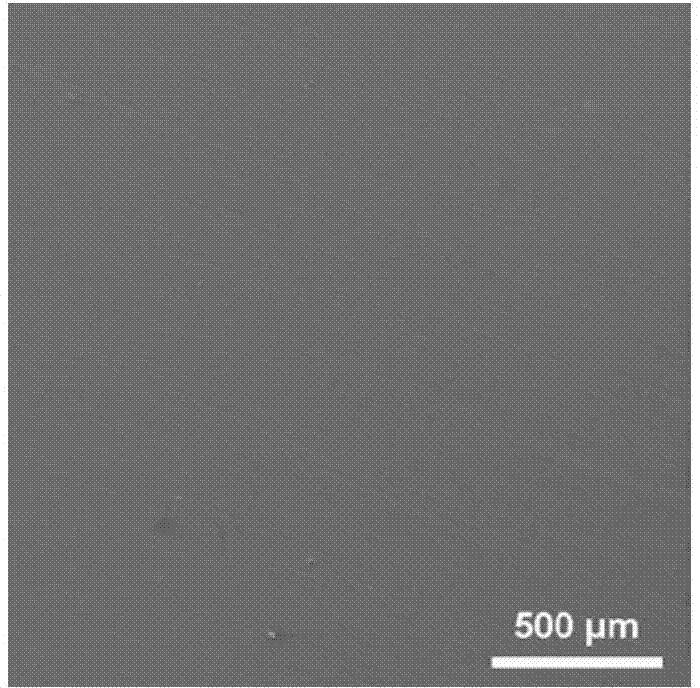

[0027] Polish the magnesium alloy until the surface is bright, and ultrasonically clean it with acetone to obtain a clean metal surface;

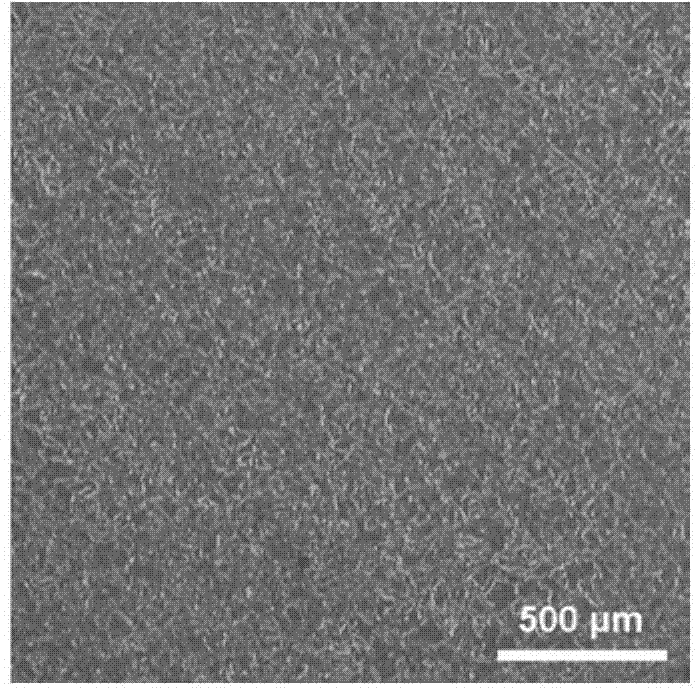

[0028] (2) Layer-by-layer self-assembly

[0029] Spin-coat the 1-ethyl-3-methylimidazole ethyl sulfate salt solution with a concentration of 5 mg / mL polyethyleneimine and sodium polystyrene sulfonate on the magnesium alloy surface after step (1) pretreatment in turn, spin The coating speed is 1500rpm, the spin coating time is 15s, wash with ultrapure water for 1 minute after each spin coating, spin coating two solutions as a layer-by-layer self-assembly cycle, a total of 25 cycles, and then blow dry with nitrogen; The concentration of 1-ethyl-3-methylimidazole ethyl sulfate salt solution was 5 mg / mL.

Embodiment 2

[0031] A method for modifying the surface of a magnesium alloy, the specific steps are as follows:

[0032] (1) Substrate pretreatment

[0033] Polish the magnesium alloy until the surface is bright, and ultrasonically clean it with acetone to obtain a clean metal surface;

[0034] (2) Layer-by-layer self-assembly

[0035] Spin-coat the 1-ethyl-3-methylimidazole ethyl sulfate salt solution with a concentration of 1 mg / mL polyethyleneimine and sodium polystyrene sulfonate on the surface of the magnesium alloy pretreated in step (1) in turn, spin The coating speed is 300rpm, and the spin coating time is 8s. After each spin coating, it is washed with ultrapure water for 1 minute. After spin coating the two solutions as a layer-by-layer self-assembly cycle, a total of 10 cycles, and then blow dry with nitrogen; The concentration of 1-ethyl-3-methylimidazole ethyl sulfate salt solution was 5 mg / mL.

Embodiment 3

[0037] A method for modifying the surface of a magnesium alloy, the specific steps are as follows:

[0038] (1) Substrate pretreatment

[0039] Polish the magnesium alloy until the surface is bright, and ultrasonically clean it with acetone to obtain a clean metal surface;

[0040] (2) Layer-by-layer self-assembly

[0041] Spin-coat the 1-ethyl-3-methylimidazole ethyl sulfate salt solution with a concentration of 10 mg / mL polyethyleneimine and sodium polystyrene sulfonate on the magnesium alloy surface after step (1) pretreatment in turn, spin The coating speed is 4000rpm, and the spin coating time is 50s. After each spin coating, wash with ultrapure water for 1 minute. After spinning the two solutions as a layer-by-layer self-assembly cycle, a total of 100 cycles, and then blow dry with nitrogen; The concentration of 1-ethyl-3-methylimidazole ethyl sulfate salt solution was 5 mg / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com