Solvent-free epoxy coating

An epoxy coating, solvent-free technology, applied in the field of coatings, can solve problems such as ineffective protection of steel, and achieve the effects of stable storage, strong corrosion resistance, and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

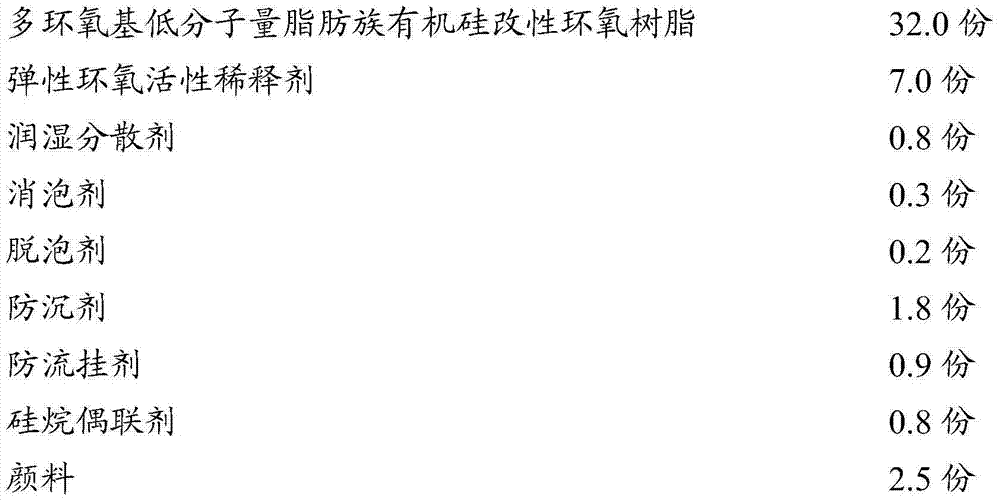

Embodiment 1

[0013] The unit is parts by mass

[0014] Main agent:

[0015]

[0016]

[0017] The main agent and the curing agent are prepared in a mass ratio of 8:1 to prepare the coating of the present invention. The specific preparation method is: adding each component in the main agent except the anti-settling agent and the anti-sagging agent to the reaction kettle Stir at high speed, disperse into a slurry, then grind to 60 microns with a grinder, add anti-settling agent and anti-sagging agent and stir evenly at low speed; then add modified m-xylylenediamine and curing accelerator to the main ingredient and stir Discharge evenly.

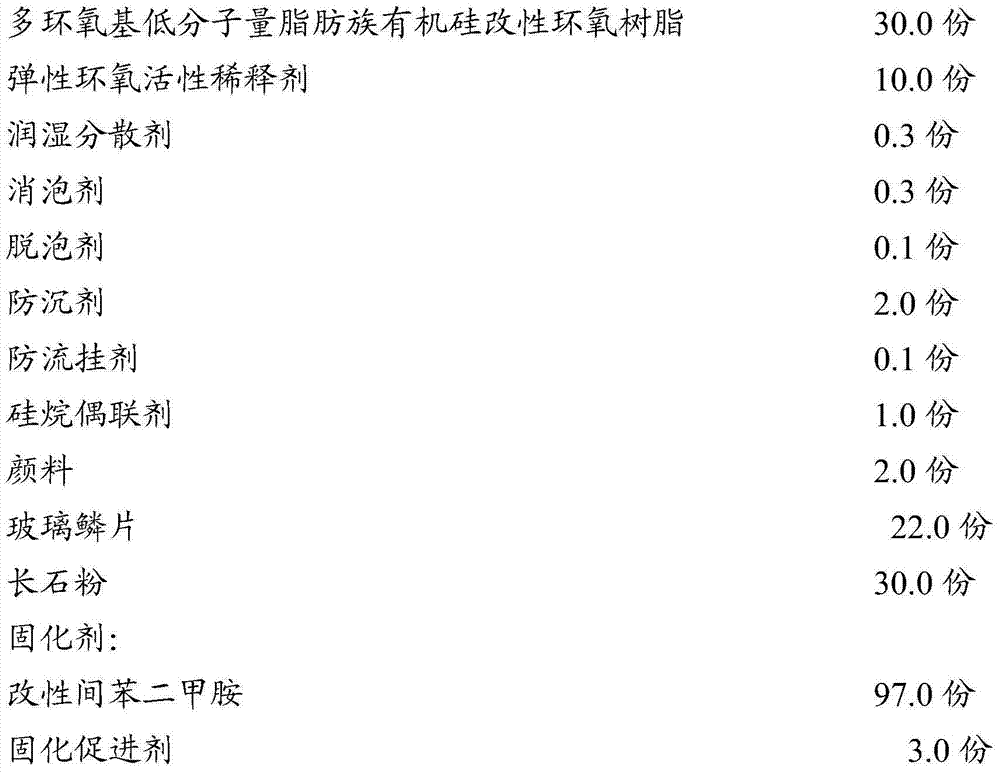

Embodiment 2

[0019] The unit is parts by mass

[0020] Main agent:

[0021]

[0022] The main agent and curing agent are prepared in a mass ratio of 8:1, and the preparation method is the same as in Example 1.

Embodiment 3

[0024] The unit is parts by mass

[0025] Main agent:

[0026]

[0027] The main agent and curing agent are prepared in a mass ratio of 8:1, and the preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com