Preparation method of 3D printing material

A 3D printing and photosensitive resin technology, applied in the field of material chemistry, can solve the problems of difficult coloring and low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

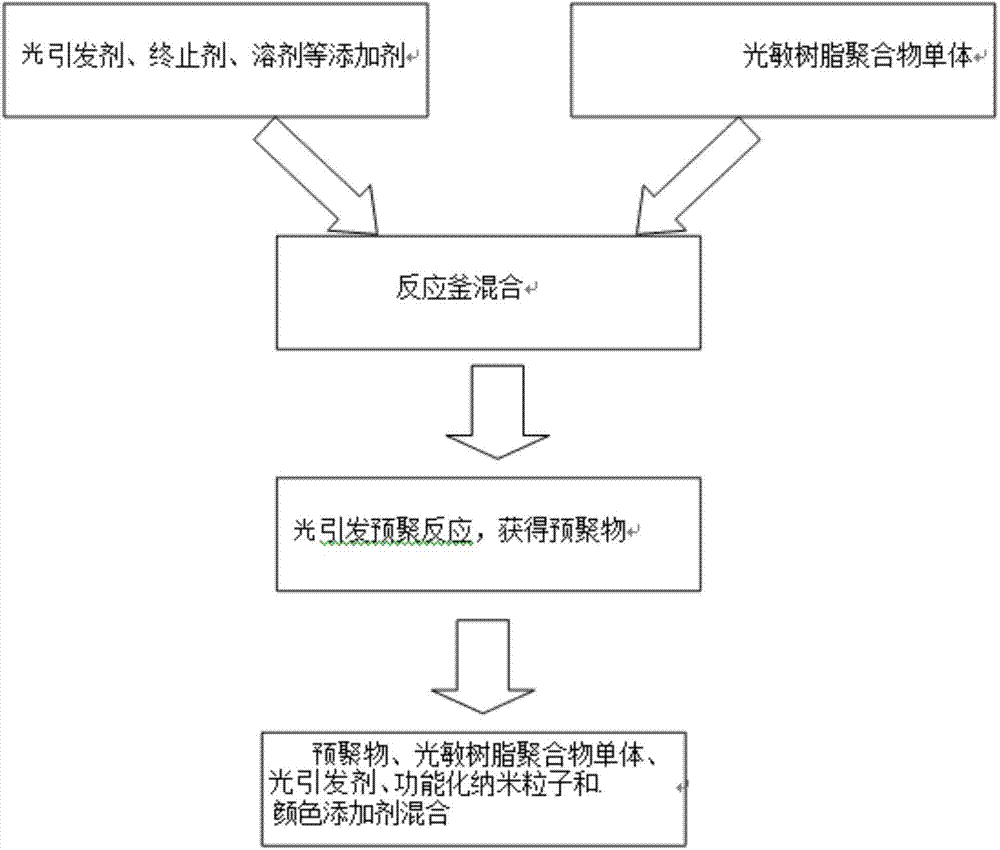

[0037] According to the first aspect provided by the present invention, the preparation method of 3D printing material comprises the following steps:

[0038] Step 1, preparing the prepolymer: dissolving the photosensitive resin polymer monomer, photoinitiator and terminator in a solvent, and performing a prepolymerization reaction at a certain temperature to obtain a prepolymer, so that the viscosity of the prepolymer is 100~ 50000cps.

[0039]In the present invention, before preparing the 3D printing material, the photosensitive resin polymer monomer, the photoinitiator and the terminator are made into a viscosity of 100-50000 cps so that the follow-up reaction is fast, and the prepared 3D printing material has excellent performance.

[0040] The present invention does not specifically limit the solvent used, it is preferred not to react with the photosensitive resin polymer monomer, photoinitiator or terminator, such as aromatic hydrocarbon solvents, aliphatic hydrocarbon s...

Embodiment 1

[0155] (1) Preparation of prepolymer: 48.8g photosensitive resin polymer monomer diethylene glycol dimethacrylate, 0.2g photoinitiator Irgacure369 (BDMB) and 1.0g terminator hydroquinone and 10.0g crosslinking The methyl etherified melamine was dissolved in 100mL of dichloromethane, and the prepolymerization reaction was carried out at 150°C to obtain a prepolymer with a polymerization degree of 50-200, and the viscosity of the prepolymer was about 10000cps;

[0156] (2) Combine the prepolymer prepared in (1) with 28.5g photosensitive resin polymer monomer diethylene glycol dimethacrylate, 0.3g photoinitiator Irgacure369 (BDMB), 1.0g terminator terephthalate Phenol, 10.0g cross-linking agent methylated melamine, 1.0g functionalized nano-particle calcium carbonate (particle size 20-40nm), 1.0g color additive TiO 2 (particle size 20-40 μm) and 0.1 g of solubilizer octylphenol polyoxyethylene ether-10 were mixed at room temperature to prepare a 3D printing material.

[0157] The...

Embodiment 2

[0159] (1) Preparation of prepolymer: 60.0g photosensitive resin polymer monomer dipentaerythritol hexaacrylate, 2.0g photoinitiator 4-methylbenzophenone, 2.0g terminator sodium dimethyldithiocarbamate and Dissolve 5.0g of cross-linking agent methylated melamine in 200mL of chloroform, and carry out prepolymerization reaction at 100°C to obtain a prepolymer with a polymerization degree of 50-200, and the viscosity of the prepolymer is about 8000cps;

[0160] (2) the prepolymer prepared in (1) and 40.0g photosensitive resin polymer monomer dipentaerythritol hexaacrylate, 8.0g photoinitiator 4-methylbenzophenone, 3.0g terminator dimethyl Sodium dithiocarbamate, 5.0g crosslinking agent methylated melamine, 5.0g functionalized nanoparticle calcium phosphate (particle size 80-100μm), 5.0g color additive cobalt blue and 2.0g solubilizer fatty alcohol polyoxyethylene ether- 7. Mix at room temperature to prepare a 3D printing material, and the viscosity of the prepared 3D printing mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com