Porous calc silicate bioceramic material, preparation method and application

A calcium silicate, porous material technology, applied in the field of biomedical materials, can solve the problems of different mechanical properties, degradation properties and regeneration efficiency requirements, limitations that have not been paid attention to by the academic community, and poor mechanical strength of porous ceramics. Efficiency and progress of bone regeneration, favorable cell migration, and easily adjustable scale effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

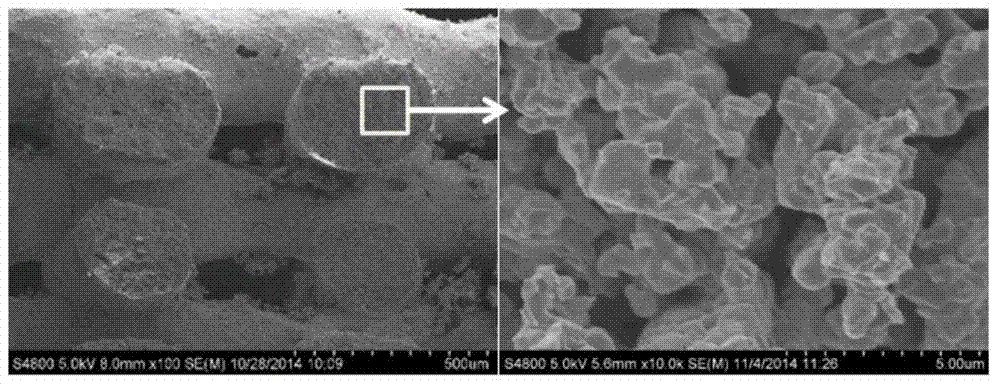

[0049] Example 1: [Zinc and magnesium co-doped β-calcium silicate porous ceramic material]

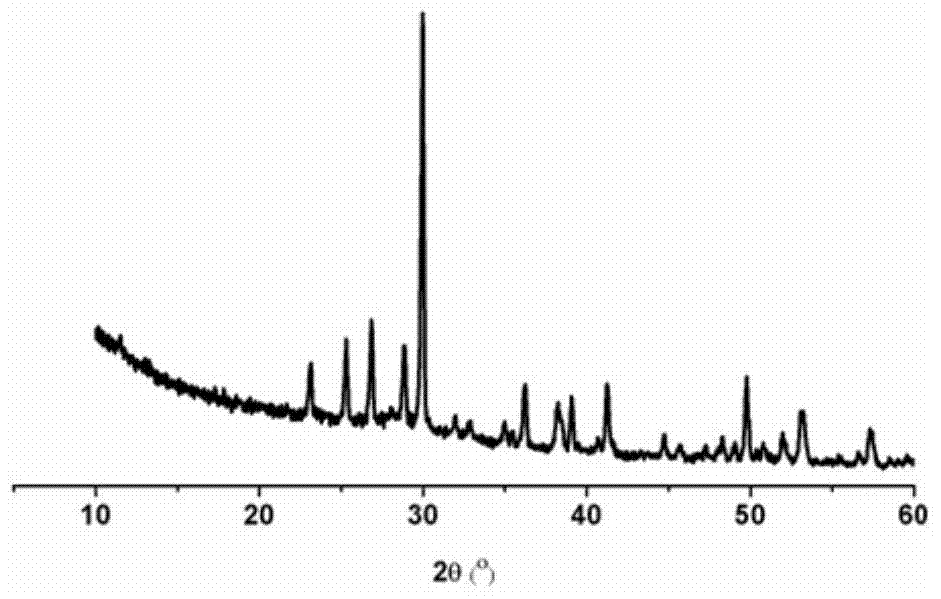

[0050] 1) Put 250 mL of 0.28 mol / L Ca (NO 3 ) 2 , 0.014 mol / L ZnCl 2 , 0.014 mol / L Mg (NO 3 ) 2 The pH of the aqueous solution was adjusted to 10.6, and the solution was added dropwise to 0.308 mol / L Na with a pH of 10.6 and a volume of 250 mL. 2 SiO 3 In the aqueous solution, continue to stir for 120 minutes after the dropwise addition, then filter the reaction sediment, wash twice with deionized water, and then wash three times with absolute ethanol, at 80 o Dry at C, after 1000 o Calcined at C for 3 hours, and then ball-milled for 4 hours to obtain zinc and magnesium co-doped β-calcium silicate powders with a particle size of 0.5-3 μm. tested by X-ray diffraction (eg figure 1 It is proved that the phase of the powder is pure β-calcium silicate, and the mass content of zinc and magnesium in the powder is 2.25% and 1.07%, respectively, by atomic absorption spectrometry.

[0...

Embodiment 2

[0052] Example 2: [Boron and magnesium co-doped α-calcium silicate ceramic porous material]

[0053] 1) Mix 500 mL of 0.30 mol / L CaCl 2 , 0.018 mol / L MgCl 2 The pH of the aqueous solution was adjusted to 10.6, and the solution was added dropwise to 0.30 mol / L Na with a pH of 10.2 and a volume of 500 mL. 2 SiO 3、 0.018 mol / L HBO 3 In the aqueous solution, continue stirring for 180 minutes after the dropwise addition, and then filter the reaction deposit, wash twice with deionized water, and then wash three times with absolute ethanol, at 120 o Drying under C, after 1220 o calcined at C for 2 hours, and then ball-milled for 6 hours to obtain powders with a particle size of 0.8-5.0 μm. The X-ray diffraction test proves that the powder is α-calcium silicate and does not exist any other crystalline phase substances (such as Image 6 The content of boron and magnesium in the α-calcium silicate powder is 0.78% and 1.18%, respectively. Boron and magnesium co-doped α-calcium sil...

Embodiment 3

[0055] Example 3: [Zinc, magnesium, boron co-doped β-calcium silicate ceramic porous material]

[0056] 1) 500 mL of 0.30 mol / L Ca (NO 3 ) 2 , 0.009 mol / L ZnCl 2 , 0.018 mol / L Mg (NO 3 ) 2 The pH value of the aqueous solution was adjusted to 10.5, and the solution was added dropwise to 0.32 mol / L Na with a pH of 10.5 and a volume of 500 mL. 2 SiO 3、 0.007 mol / L HBO 3 In the aqueous solution, continue to stir for 90 minutes after the dropwise addition, then filter the reaction sediment, wash it with deionized water 4 times, and then wash it with absolute ethanol 2 times, at 120 o Dry at C, after 950 o Calcined at C for 2 hours, and then ball-milled for 6 hours to obtain zinc, magnesium and boron co-doped β-calcium silicate powder with particle size of 0.3-2 μm. The X-ray diffraction test proves that the powder phase is pure β-calcium silicate, and there is no other crystalline phase. The atomic absorption spectrometry analysis and test show that the mass content of zinc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com