Preparation method for transition metal oxide nanoparticle

A technology for nanoparticles and transition metals, applied in the field of preparing transition metal nanoparticles, can solve problems such as unfavorable large-scale production, cumbersome methods, time-consuming, etc., and achieves the effects of strong versatility, simple process, and prevention of particle aggregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

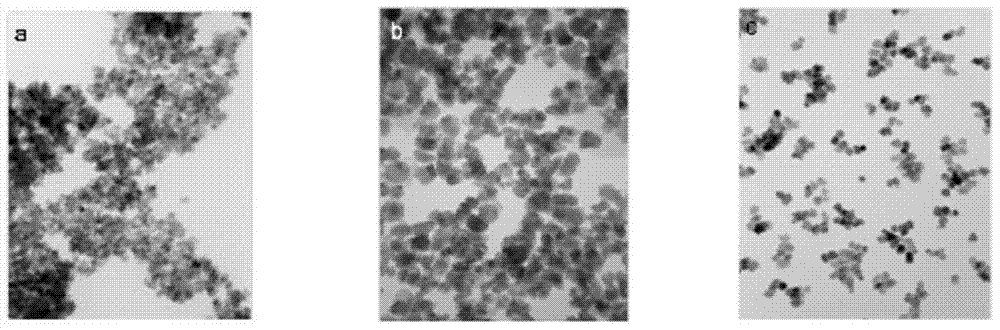

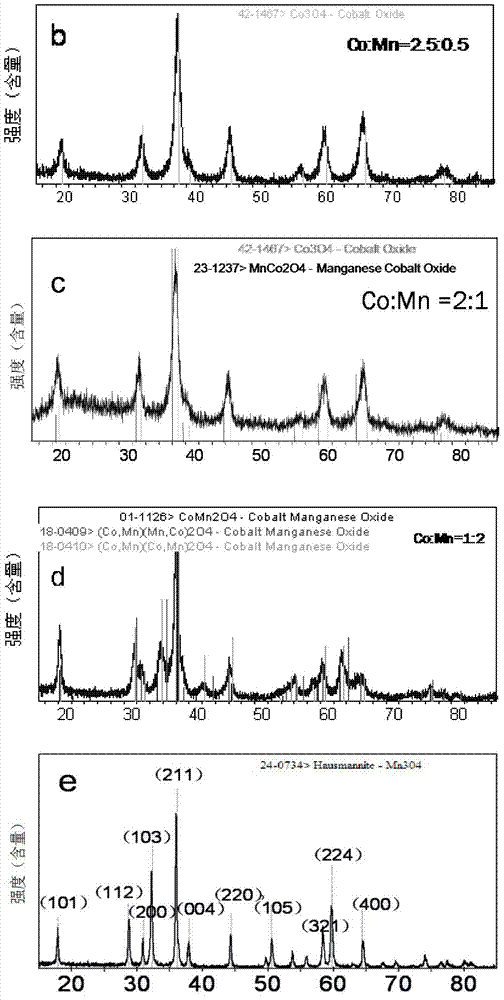

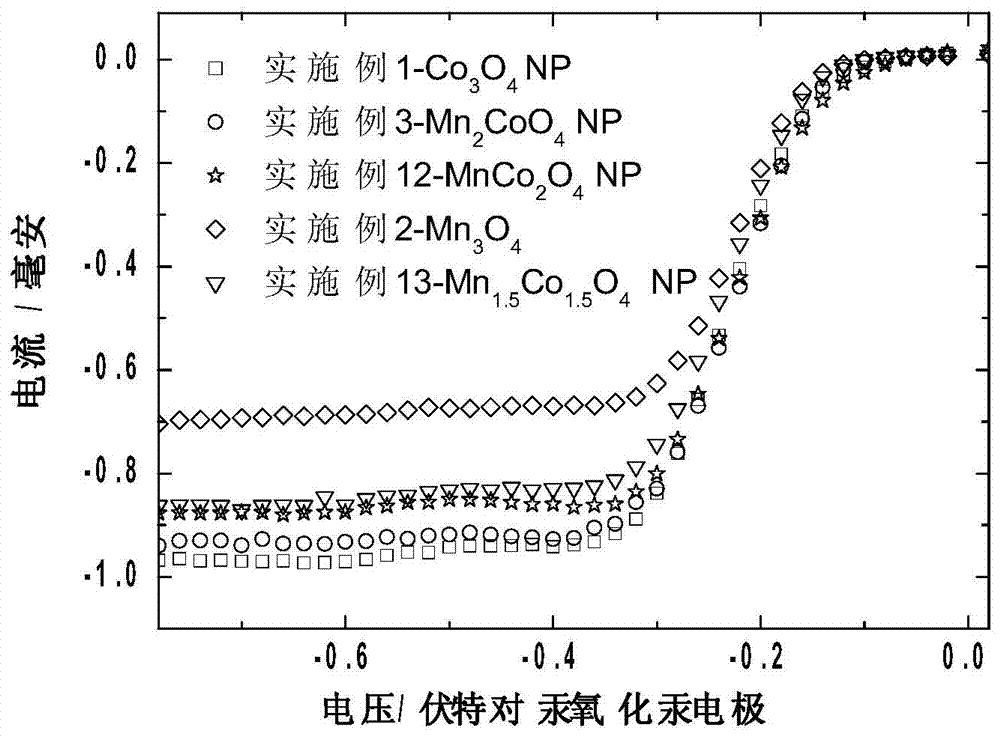

Embodiment 1

[0026] Add 0.5g of cobalt acetate tetrahydrate to 25ml of water, ultrasonically disperse until uniform, then add 2.5mL of ammonia solution with a mass fraction of 25%, and stir in the air for a certain period of time for 15min. Put the above suspension in an oil bath at 100°C reflux in 3h, the black Co 3 o 4 precipitation.

Embodiment 2

[0028] Add 0.5g of manganese acetate tetrahydrate to 25ml of ethanol, ultrasonically disperse until uniform, then add 2.5mL of ammonia solution with a mass fraction of 25%, put it in the air and stir for a certain period of time for 15min, put the above suspension in an oil bath at 100°C reflux in 3h, the brown-yellow Mn 3 o 4 precipitation.

Embodiment 3

[0030] Add 0.17g manganese acetate tetrahydrate and 0.33g Co salt tetrahydrate acetate to 25ml ethanol, ultrasonically disperse until uniform, then add 2.5mL ammonia solution with a mass fraction of 25%, and stir in the air for a certain period of time for 15min to dissolve the above suspension Reflux in an oil bath at 100°C for 3 hours to obtain CoMn 2 o 4 precipitation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com