Preparation method for superstructure Au/Ag@Al2O3@Ag nanosphere array and SERS performance of superstructure Au/Ag@Al2O3@Ag nanosphere array

A technology of nanotube arrays and nanospheres, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems that the nanogap cannot generate electromagnetic field enhancement, is not conducive to SERS performance, and achieves high activity , good repeatability, wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

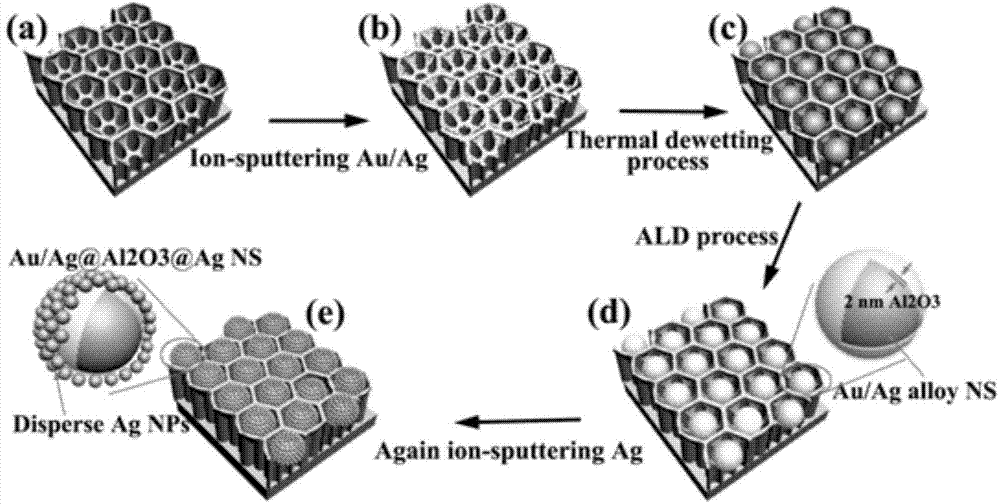

[0022] Example 1: Superstructure Au / AgAl 2 O 3 Preparation of Ag Nanosphere Array

[0023] (1) Preparation of titanium dioxide nanobowl array

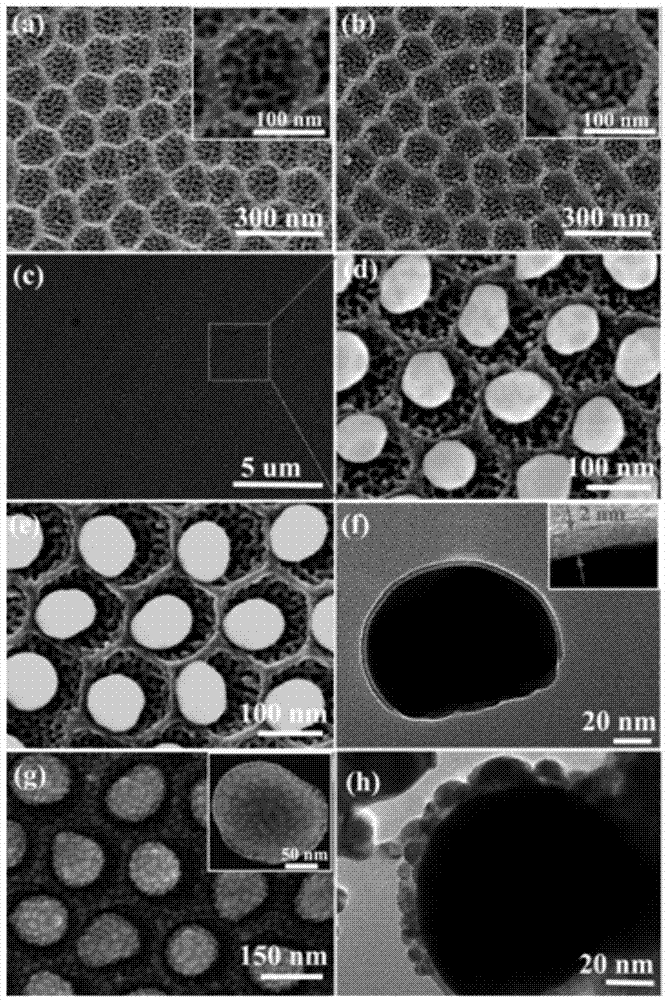

[0024] Oxidize the pure titanium sheet in 0.26M ammonium fluoride glycol solution at 50 V oxidation voltage for 1.5 hours to obtain TiO 2 Nanotube array; then the generated TiO is removed by ultrasonic oscillation 2 Nanotube array, leaving lighter TiO on the titanium sheet 2 Nanobowl array. Finally, the titanium sheet with the shallower nanobowl array is oxidized in 0.26M ammonium fluoride glycol solution at 10 V oxidation voltage for 40 minutes to obtain hierarchical TiO 2 Nanobowl array; from figure 1 a It can be seen that the diameter of the nanobowl is about 150nm and the depth is about 60nm.

[0025] (2) Preparation of Au / Ag nanosphere array

[0026] TiO 2 The nanobowl array is used as a template, and two kinds of Au and Ag nanoparticles are ion sputtered sequentially to form an Au / Ag nanoparticle film (such as figure 2 b) Covered in...

Embodiment 2

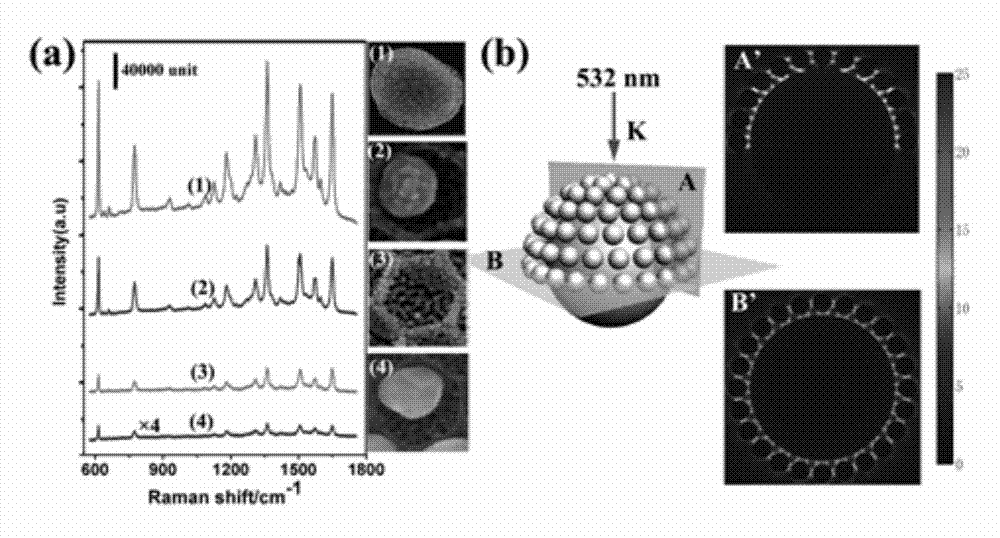

[0029] Example 2: Superstructure Au / AgAl 2 O 3 SERS performance test of Ag nanosphere array

[0030] By selecting three other SERS substrates with different structures and a superstructure Au / AgAl 2 O 3 Compare the SERS performance of the Ag nanosphere array and evaluate its SERS performance. The other three selected substrates are: TiO 2 Nanobowl array template array ion sputtering Au and Ag nanoparticles, Au / Ag nanoparticle ball arrays, and Au / AgAg nanosphere arrays directly obtained by ion sputtering Ag nanoparticles on Au / Ag composite nanospheres (Au There is no Al between the Ag particles in the / AgAg nanospheres and the Au / Ag nanospheres 2 O 3 Dielectric layer separation). During the SERS performance test, these different substrates were tested in 10 -7 Soak in M rhodamine (R6G) solution for 1 hour, and measure its Raman signal after drying at room temperature. image 3 a is 10 on the left -7 MR6G adsorbs the SERS spectra measured on these four substrates, image 3 a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com