Etomidate fat emulsion concentrated solution, preparation method and application thereof

A technology of etomidate and fat emulsion, applied in the directions of emulsion delivery, oil/fat/wax inactive ingredients, pharmaceutical formulations, etc., can solve the problems of oil-water stratification, inability to perform clarity detection, complex preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0150] Embodiment 1: the preparation of etomidate fat emulsion concentrate sample 1

[0151] Its composition is as follows:

[0152] Etomidate 2.5g

[0153] Medium-chain fatty acid glycerides (Capmul MCM, Abitec) 25g

[0154] 30g soybean oil

[0155] 1,2-propanediol 9 grams

[0156] Soy Lecithin (Epikuron 170, Degussa) 10g

[0157] Polyglyceryl Oleate 3 g

[0158] Tween 80 9 grams

[0159] Polyethylene glycol lauryl hydroxystearate (Solutol HS 15, BASF) 11 g

[0160] Sodium Oleate 0.2g

[0161] Vitamin E 0.3g

[0162] The preparation method of this etomidate fat emulsion concentrate is as follows:

[0163] 1) At 20°C, add the above-mentioned weight of soybean lecithin and polyglycerol oleate into medium-chain fatty acid glycerides and soybean oil, and stir at 20,000 rpm until a transparent and clear solution is formed;

[0164] 2) Add the above-mentioned weight of 1,2-propanediol and etomidate to the product of step 1) at 20°C, and keep stirring at 200rpm until...

Embodiment 2

[0167] Embodiment 2: the preparation of etomidate fat emulsion concentrate sample 2

[0168] Its composition is as follows:

[0169] Etomidate 1.5g

[0170] Medium chain fatty acid triglycerides (Crodamol, GTCC) 70g

[0171] 1,2-Propanediol 8g

[0172] Soy Lecithin (Epikuron 170, Degussa) 7.5g

[0173] Polyglyceryl Oleate 1 g

[0174] Tocopheryl Polyethylene Glycol Succinate 4g

[0175] Tween 80 3.7g

[0176] Polyethylene glycol lauryl hydroxystearate (Solutol HS 15, BASF) 4 g

[0177] Vitamin E 0.3 grams

[0178] The preparation method of this etomidate fat emulsion concentrate is as follows:

[0179] 1) At 45°C, add the above-mentioned weight of soybean lecithin and polyglycerol oleate to medium-chain fatty acid triglycerides, and stir at 2000 rpm until a transparent and clear solution is formed;

[0180] 2) Add the above-mentioned weight of 1,2-propanediol and etomidate to the product of step 1) at 35°C, and keep stirring at 1000rpm until the whole system is ...

Embodiment 3

[0183] Embodiment 3: the preparation of etomidate fat emulsion concentrate sample 3

[0184] Its composition is as follows:

[0185] Etomidate 2g

[0186] Caprylic Capric Glycerides (Miglyol 812, SASOL) 65g

[0187] 1,2-Propanediol 12g

[0188] Soy Lecithin (Epikuron 170, Degussa) 12g

[0189] Tween 80 3 grams

[0190] Polyethylene glycol lauryl hydroxystearate (Solutol HS 15, BASF) 5.5 g

[0191] Sodium Oleate 0.3g

[0192] Vitamin A 0.2g

[0193] The preparation method of this etomidate fat emulsion concentrate is as follows:

[0194] 1) At 30°C, add the above-mentioned weight of soybean lecithin to caprylic capric glyceride, and stir at 10,000 rpm until a transparent and clear solution is formed;

[0195] 2) Add the above-mentioned weight of 1,2-propanediol and etomidate to the product of step 1) at 45°C, and continue stirring at 1000 rpm until the whole system is transparent;

[0196] 3) Add the above-mentioned weight of Tween 80, polyethylene glycol lauryl hy...

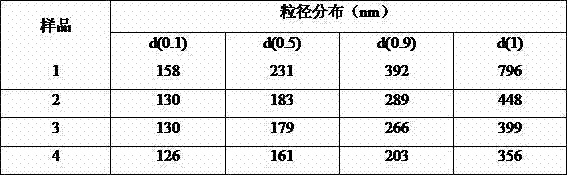

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com