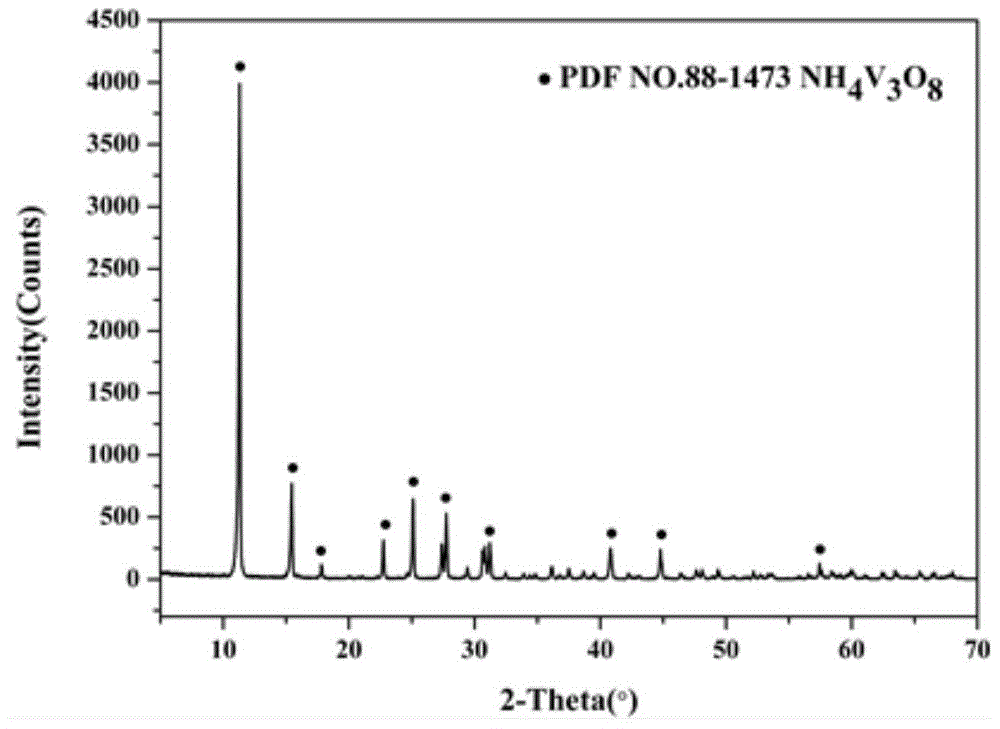

Method for preparing biochar/ammonium vanadate lithium ion cell cathode material

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of difficult control of the reaction process, low product purity, high reaction temperature, etc., and achieve improved cycle stability, low reaction temperature, and synthesis The effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

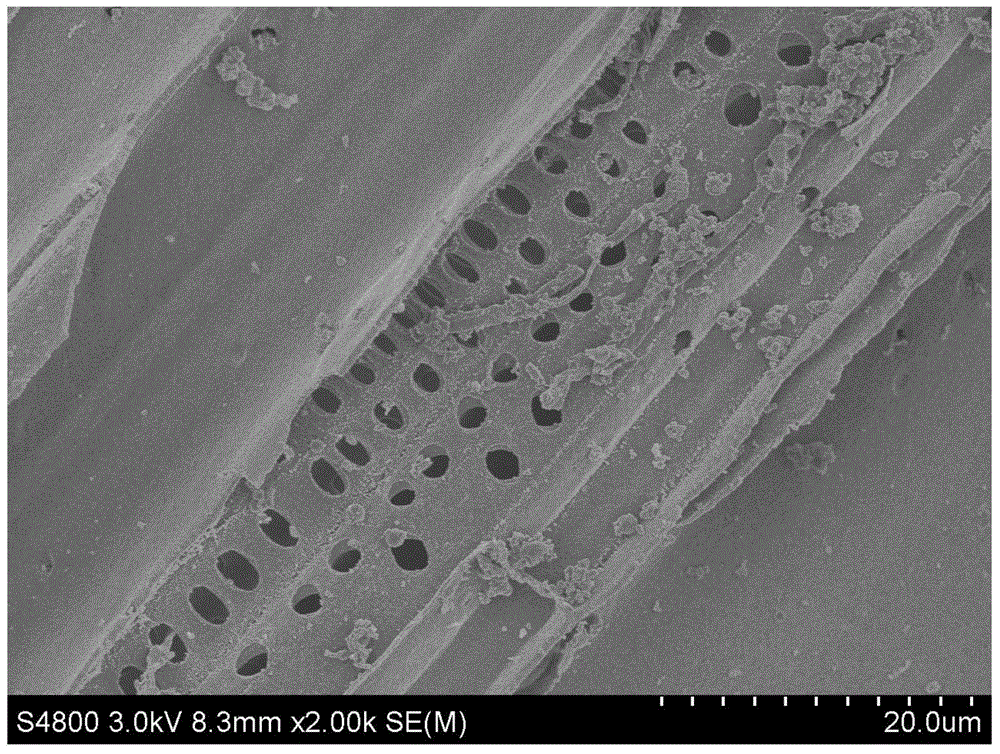

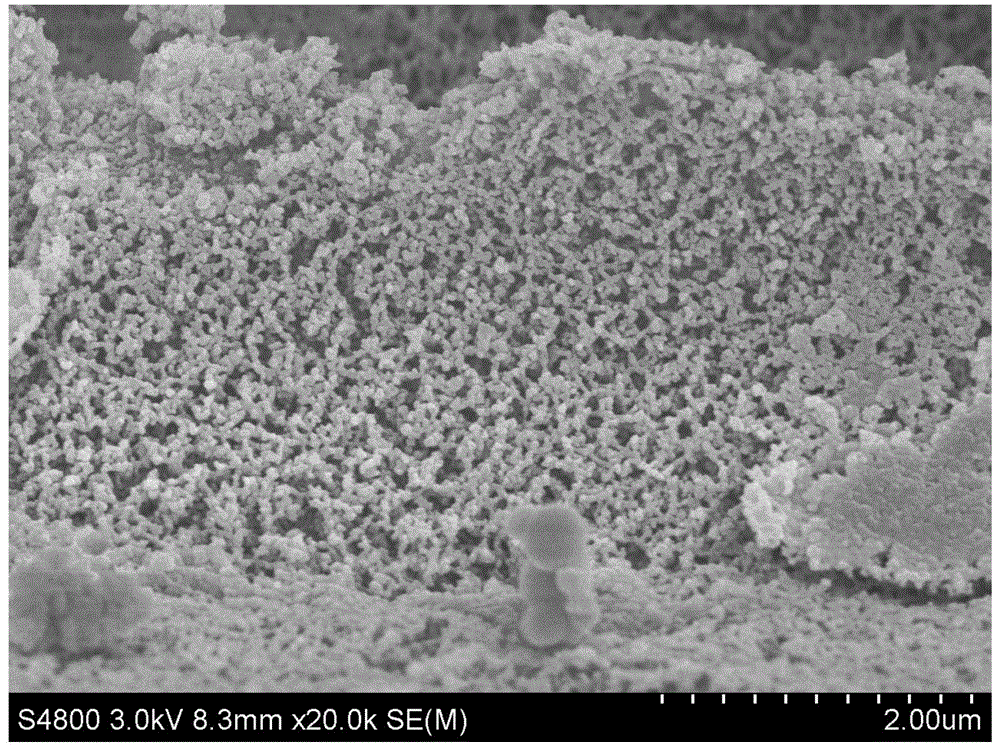

[0038] A preparation method of biological carbon / ammonium vanadate lithium ion battery cathode material, comprising the following steps:

[0039] (1) Wash the biomass prefabricated body (biomass prefabricated body is one of banana peel, shrimp shell, sycamore leaf, wheat straw or corn straw) to remove surface impurities, and cut it into pieces with a side length of 4-6mm Uniform block A;

[0040] (2) Dry the uniform block A at room temperature for 0.5-1 hour to obtain block B;

[0041] (3) Add the concentration of 2~5mol·L to block B -1 Carry out homogeneous reaction after the concentrated nitric acid, the condition of homogeneous reaction is: be heated up to 150 ℃~180 ℃ with the heating rate of 15 ℃ / min, keep warm for 20~50min, then naturally cool to room temperature, obtain reaction product C;

[0042](4) After the reaction product C is suction filtered and dried, it is moved into a tube-type atmosphere furnace for carbonization. The tube-type atmosphere furnace is fed wit...

Embodiment 1

[0049] (1) the sycamore leaves are washed to remove surface impurities, and shredded to obtain uniform block A with a side length of 4 mm;

[0050] (2) Dry the uniform block A at room temperature for 0.5h to obtain block B;

[0051] (3) Add the concentration of 2mol L to block B -1 After the concentrated nitric acid was added, the temperature was raised to 150°C at a heating rate of 15°C / min, and then kept for 20 minutes, and then naturally cooled to room temperature to obtain the reaction product C;

[0052] (4) After the reaction product C is suction filtered and dried, it is moved into a tubular atmosphere furnace for carbonization. The tubular atmosphere furnace is fed with nitrogen. The carbonization conditions are: heat the tubular atmosphere furnace to 50°C in 10 minutes, and raise the temperature to 600°C in 75 minutes. After heat preservation for 180min, the carbonized product D was obtained;

[0053] (5) Soak the carbonized product D in ethanol, then wash three tim...

Embodiment 2

[0059] (1) Wash the wheat stalks to remove surface impurities, and shred them to obtain uniform block A with a side length of 6 mm;

[0060] (2) Dry the uniform block A at room temperature for 1 hour to obtain block B;

[0061] (3) Add concentration of 5mol L to block B -1 After the concentrated nitric acid was added, the temperature was raised to 180°C at a heating rate of 15°C / min, and then kept at 180°C for 50 minutes, and then naturally cooled to room temperature to obtain reaction product C;

[0062] (4) After the reaction product C is suction filtered and dried, it is moved into a tubular atmosphere furnace for carbonization. Nitrogen is introduced into the tubular atmosphere furnace. The carbonization conditions are as follows: heat the tubular atmosphere furnace to 50°C in 10 minutes, and raise the temperature to 800°C in 75 minutes. After the heat preservation for 60min, the carbonized product D was obtained;

[0063] (5) The carbonized product D is soaked in ethano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com