A kind of manufacturing method of wireless radio frequency remote optical cable, electric cable and photoelectric composite cable for communication

A technology of radio frequency and manufacturing method, which is applied in the manufacture of cables/conductors, power cables including optical transmission elements, power cables, etc., can solve problems such as poor effect, unsatisfactory solar radiation resistance, and unsatisfactory softness performance. , to achieve the effect of simple structure, high qualified rate of finished products and strong resistance to solar radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

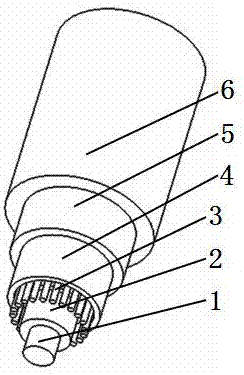

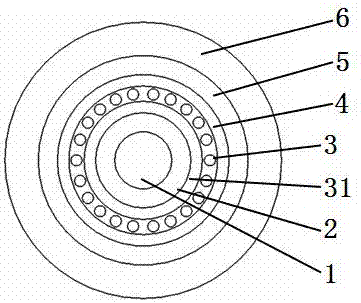

[0027] please see figure 1 with figure 2 , a wireless radio frequency remote optical cable for communication, characterized in that it consists of a central strength member 1 extruded with a plastic layer 2, an inner cushion 31 located outside the plastic layer 2, an outer cushion 4 located outside the inner cushion, and an inner cushion 4 located outside the inner cushion. The light transmission body 3 between the cushion layer and the outer cushion layer, the protective layer 5 located outside the outer cushion layer, and the outer sheath 6 coated outside the protective layer by extrusion; the inner cushion layer is close to the plastic layer, and the light transmission The body is distributed between the inner cushion layer and the outer cushion layer, and only one layer of light transmission body can be placed in the gap between the inner cushion layer and the outer cushion layer, and the protective layer is close to the outer cushion layer; the central reinforcement is m...

Embodiment 2

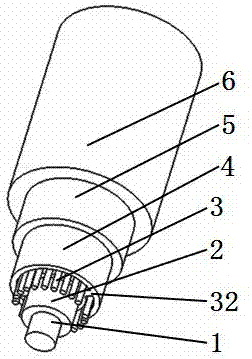

[0056] please see image 3 with Figure 4 , wireless radio frequency remote optical cable for communication, basic implementation example 1, the difference is: the inner cushion and the outer cushion are connected by two connecting bars 32, and the optical transmission body is located between the inner cushion and the outer cushion In the gap between them, the inner cushion layer, the connecting strip and the outer cushion layer can be integrally formed by extrusion.

[0057] Of course, it can also be the wireless remote radio cable and photoelectric composite cable as in the embodiment 1.

Embodiment 3

[0059] please see Figure 5 with Image 6 , wireless radio frequency remote optical cable for communication, basic implementation example 2, the difference is: the inner cushion and the outer cushion are connected by four connecting bars 32, and the optical transmission body is located between the inner cushion and the outer cushion In the gap between them, the inner cushion layer, the connecting strip and the outer cushion layer can be integrally formed by extrusion.

[0060] Of course, it can also be the wireless remote radio cable and photoelectric composite cable as in the embodiment 1.

[0061] Of course, the inner cushion layer and the outer cushion layer can also be connected through other multiple connecting bars, which can realize flexible distribution of optical transmission body and / or power distribution.

[0062] The wireless radio remote optical cable for communication, the radio remote remote cable or the radio radio remote photoelectric composite cable describ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com