Shape memory fiber, manufacturing method thereof and textile product manufactured by shape memory fiber

A memory fiber and textile technology, applied in the field of shape memory fiber, can solve problems such as low recovery force, shape fixity, environmental pollution of spinning, and impact on human health, and achieve good comfort and high environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

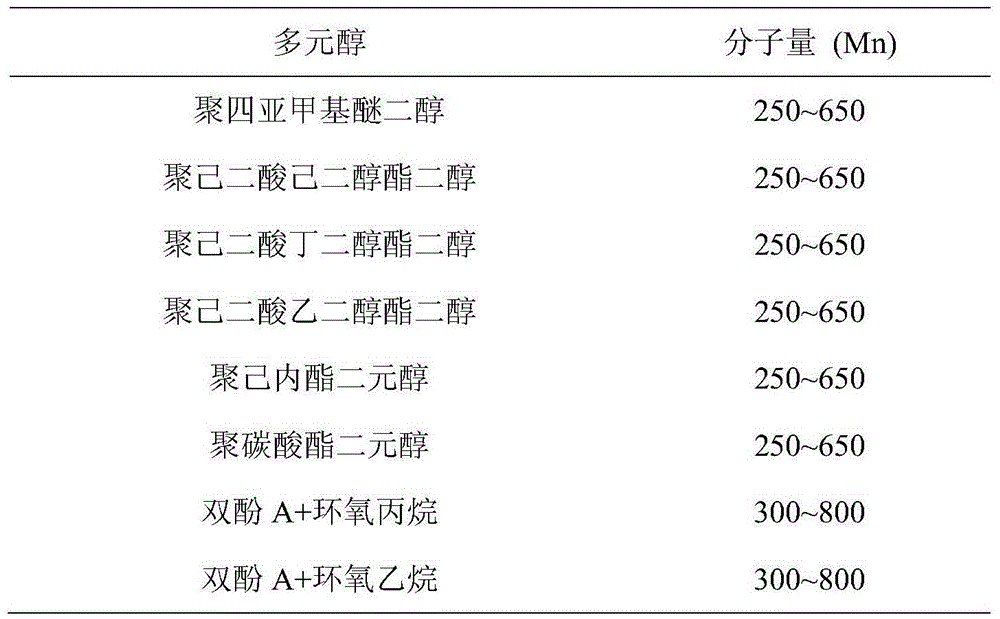

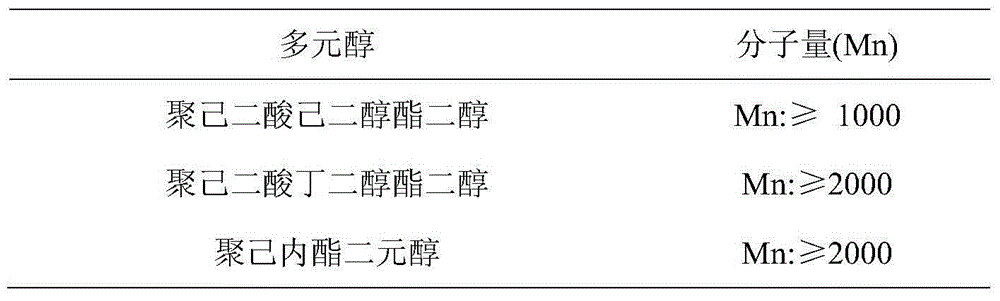

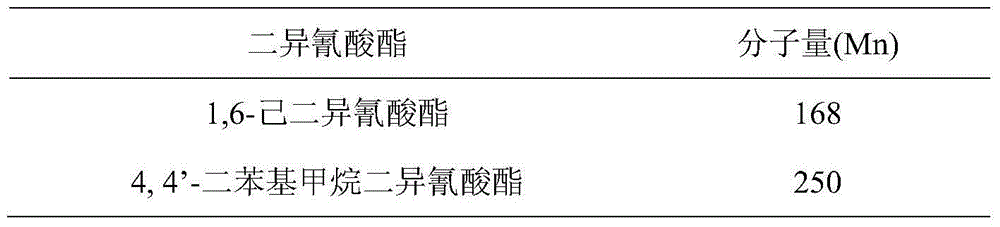

Method used

Image

Examples

example (1)

[0037] Example (1): Tg-type shape memory fiber 1 (SMF1)

[0038] Shape memory fibers were prepared by bulk polymerization using polycaprolactone diol (PCL) (molecular weight: 530), 1,4-butanediol and MDI, where PCL was used as the soft segment, MDI and 1,4-butanediol as a hard chain segment. The molar ratio of MDI, 1,4-butanediol and PCL was 1.5:0.5:1. The contents of soft segment and hard segment were 56% and 44%, respectively. First dehydrate PCL at 90°C for 2 hours under reduced pressure, add the measured 1,4-butanediol (through 4A molecular sieve to remove water) and MDI, stir rapidly for 15 seconds, and then pour into the pre-dried stainless steel tray Inside (the tray is coated with polytetrafluoroethylene), matured in a vacuum oven at 100 degrees for 24 hours, after being crushed, extruded from a single-screw extruder and pelletized. equipped with Measured by high performance liquid chromatography with a rEX refractive index detector; the obtained shape-memory poly...

example (2)

[0045] Example (2): Tg-type shape memory fiber 2 (SMF2)

[0046] Shape memory fibers were prepared by bulk polymerization using polybutylene adipate diol (PBA) (molecular weight 400), 1,4-butanediol and MDI, where PBA was used as the soft segment, MDI and 1,4 -Butanediol as hard segment. The molar ratio of MDI, 1,4-butanediol and PBA is 2:1:1. The soft segment content and the hard segment content are 40% and 60% respectively. First dehydrate the PBA at 90°C for 2 hours under reduced pressure, add the measured 1,4-butanediol (through 4A molecular sieve to remove water) and MDI, stir rapidly for 15 seconds, and then pour into the pre-dried stainless steel tray Inside (the tray is coated with polytetrafluoroethylene), matured in a vacuum oven at 100 degrees for 24 hours, after being crushed, extruded from a single-screw extruder and pelletized. equipped with The high-performance liquid chromatographic measurement of the rEX refractive index detector shows that the obtained s...

example (3)

[0054] Example (3): Tg-type shape memory fiber 3 (SMF3)

[0055] Shape memory fibers were prepared by bulk polymerization using polytetramethylene ether glycol (PTMEG) (molecular weight: 650), 1,4-butanediol and MDI, where PTMEG was used as the soft segment, MDI and 1,4-butane Diols serve as hard segments. The molar ratio of MDI, 1,4-butanediol and PTMEG was 1.5:0.5:1. The soft segment content and hard segment content were 61% and 39%, respectively. First dehydrate PTMEG at 90°C for 2 hours under reduced pressure, add measured 1,4-butanediol (water removed through 4A molecular sieve) and MDI, stir rapidly for 15 seconds, and then pour into the pre-dried stainless steel tray Inside (the tray is coated with polytetrafluoroethylene), matured in a vacuum oven at 100 degrees for 24 hours, after being crushed, extruded from a single-screw extruder and pelletized. equipped with The high-performance liquid chromatographic measurement of the rEX refractive index detector shows tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com